Planar ultrasonic motor driven based on H-shaped piezoelectric transducer structure and working mode thereof

A piezoelectric transduction and planar technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of slow motor speed, achieve stable operation, avoid The effect of plane motion error and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

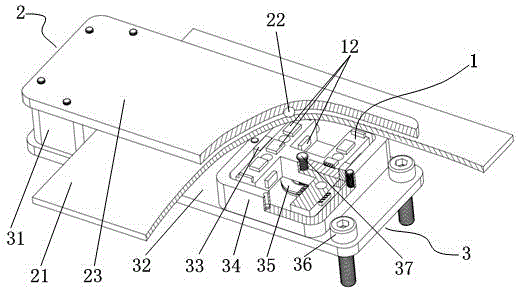

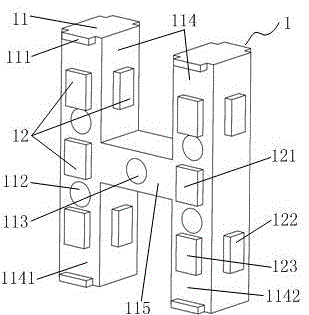

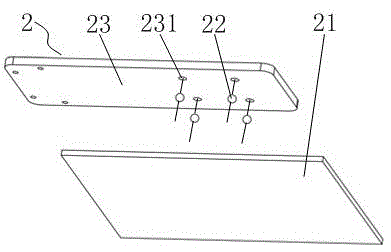

[0037] Embodiment: The present invention is based on a planar ultrasonic motor driven by an H-shaped piezoelectric transducer structure, including a stator assembly 1, a mover assembly 2 and a support assembly 3, see Figure 1 to Figure 4 . The support assembly 3 is connected to the mover assembly 2 through the fixed vertical plate 31 on one side of the bottom plate 32, the stator assembly 1 is located between the support assembly 3 and the mover assembly 2, and is connected to the mover assembly 2 through the driving foot 111, and The stator fixing screw 37 of the support assembly 3 is connected to the bottom plate 32; the stator assembly 1 includes an H-shaped structural plate 11 and a piezoelectric ceramic excitation assembly 12, and the H-shaped structural plate 11 is connected by two longitudinal rods 114 and the middle section of the longitudinal rod 114. The horizontal bar 115 is formed, the vertical bar 114 is provided with an adjustment hole 112, and the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com