Co-moving hydraulic shears without stand

A shearing machine and motion technology, applied in shearing devices, devices for shearing forming blanks, shearing machine equipment, etc., can solve problems such as large size, large structural complexity, and increased cost, and achieve fewer components and cost savings. , the effect of compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

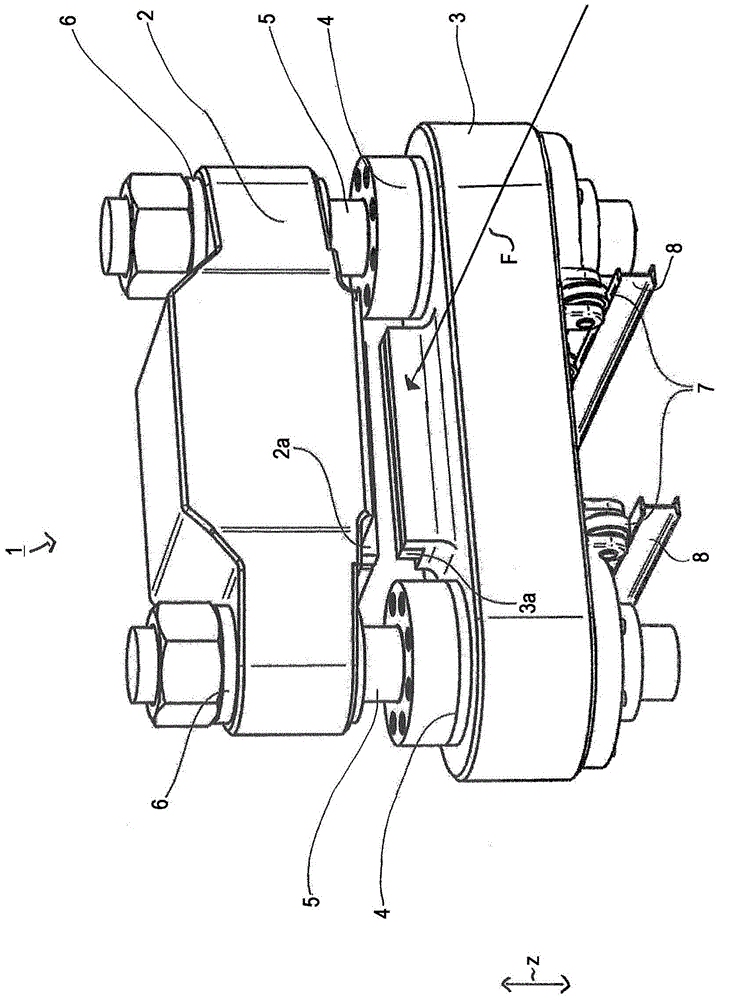

[0019] figure 1 The shearing machine 1 according to the invention is shown in perspective illustration. The shearing machine 1 includes an upper knife rest 2 and a lower knife rest 3 . An upper knife 2 a and a lower knife 3 a are installed at the upper knife rest 2 and the lower knife rest 3 . The upper knife rest 2 can move relative to the lower knife rest 3 . For this purpose, two hydraulic cylinders 4 are mounted on the lower tool carrier 3 , wherein corresponding piston rods 5 of the hydraulic cylinders 4 are connected to the upper tool carrier 2 . Through the control of the hydraulic cylinder 4, the upper tool rest 2 can move up and down relative to the lower tool rest 3, that is, along the figure 1 Movement in the direction of the arrow z shown in.

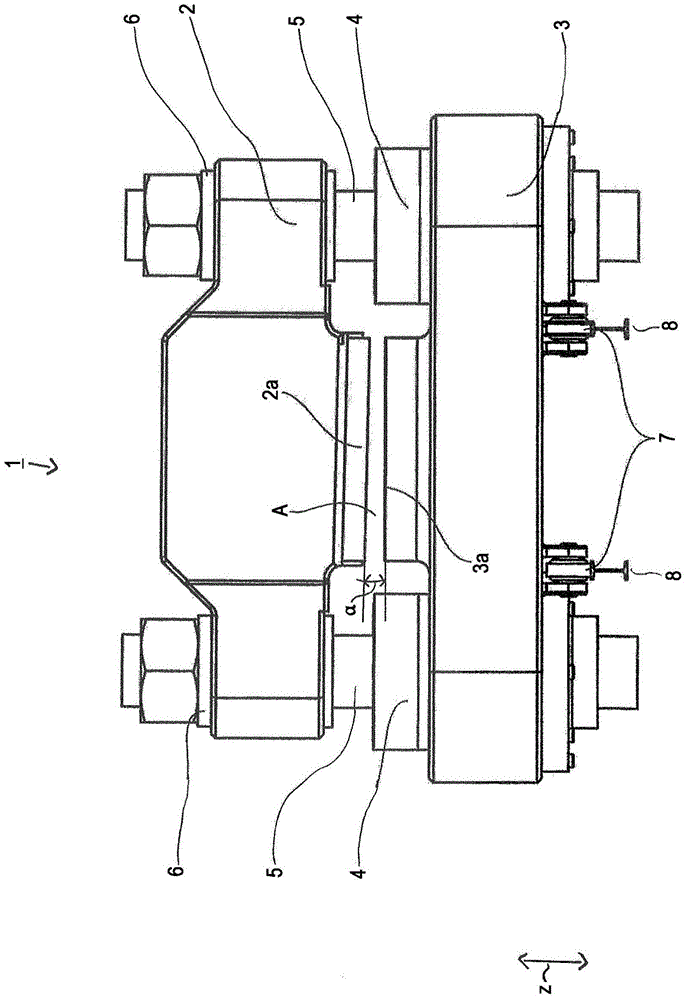

[0020] figure 2 Shown in side view from the front figure 1 The shearing machine1. This means that the lower tool holder 3 serves as a receiving element for the two hydraulic cylinders 4 . When the hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com