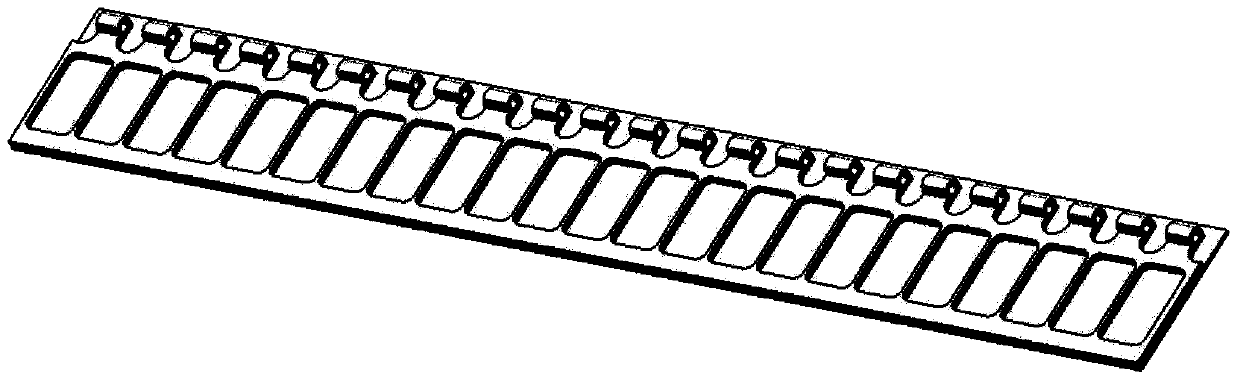

A hinged part drilling jig

A drilling jig, hinged technology, used in drilling/drilling equipment, manufacturing tools, components of boring machines/drilling machines, etc., can solve problems such as drilling deep holes, and achieve the effect of ensuring accuracy and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

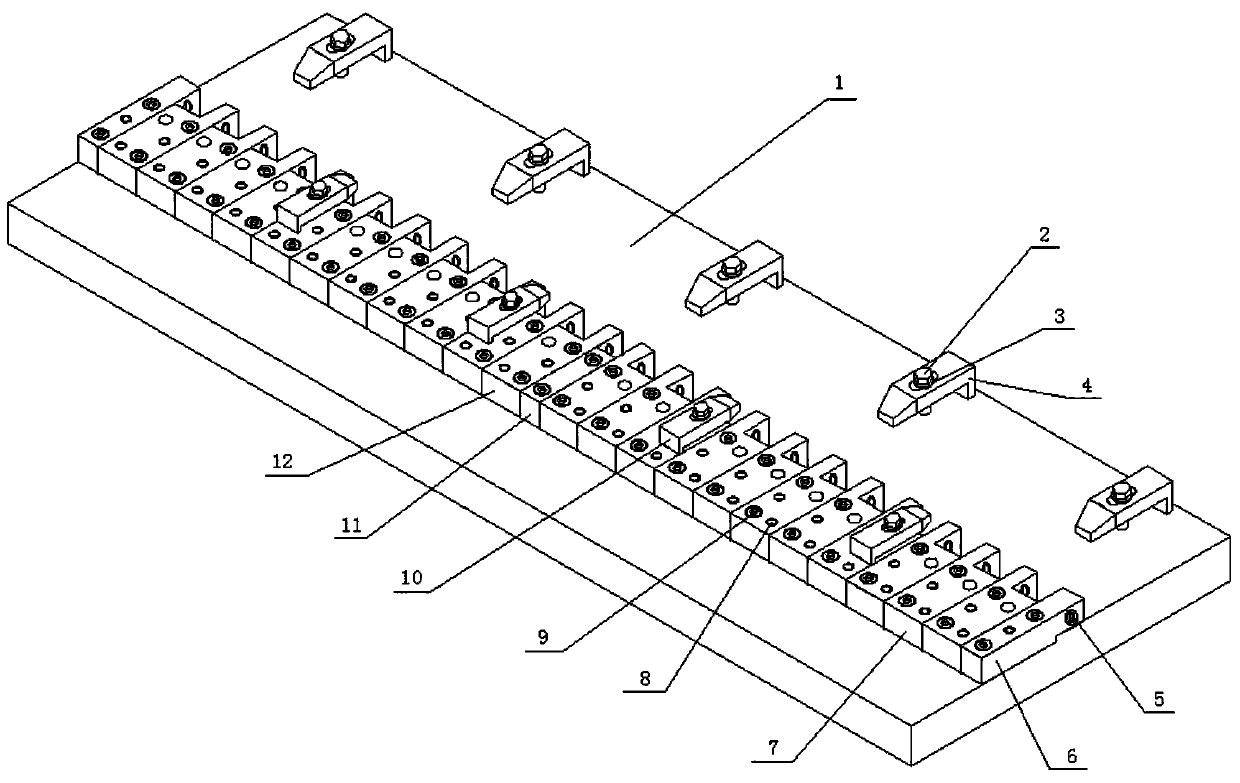

[0013] The present invention will be described in detail below with reference to the drawings and embodiments.

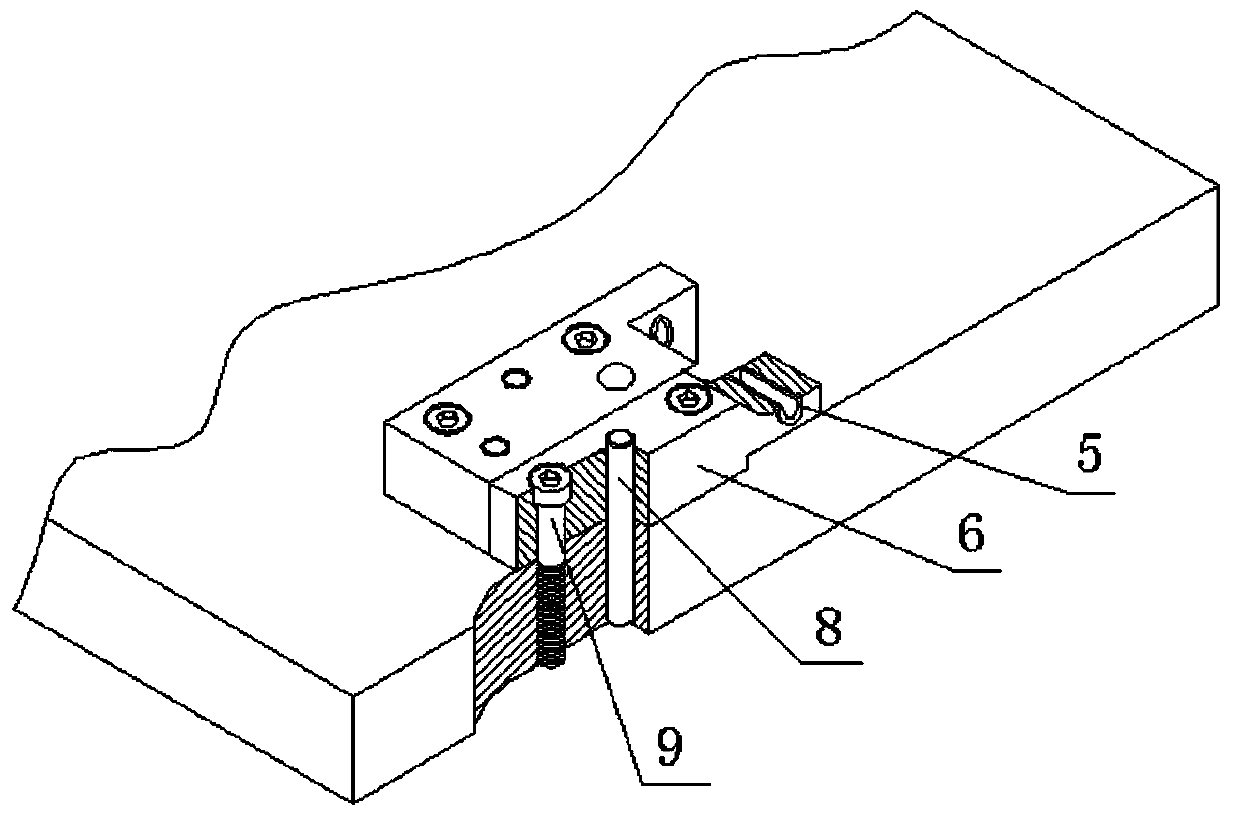

[0014] The present invention provides a hinge type parts drilling fixture, which includes: a support plate 1, a hexagonal head bolt 2, a gasket 3, a long pressing plate 4, a bushing 5, an end positioning block 6, a left-offset positioning block 7, Positioning pin 8, inner hexagonal bolt 9, short pressing plate 10, adjustment block 11, right-offset positioning block 12;

[0015] The upper surface of the support plate 1 is designed to be step-shaped, and the upper, lower and side surfaces of the step are finished, and the parallelism and straightness reach IT7 accuracy according to GB1800-79. The side surface of the step is the reference for installing the positioning block, so that the positioning hole of the positioning block can be located on a straight line.

[0016] A number of positioning blocks are installed on the support plate 1. The lower surface of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com