Controllable fast reciprocating point feed grinding system and grinding method based on grinding temperature empirical model

A grinding temperature and empirical model technology, applied in the field of mechanical grinding, can solve the problems of thermal damage to the grinding surface, reduce the service life of the grinding wheel, and affect the grinding quality, so as to ensure the processing quality, improve the processing efficiency, and reduce the grinding wheel. The effect of blocking and passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific examples.

[0025] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

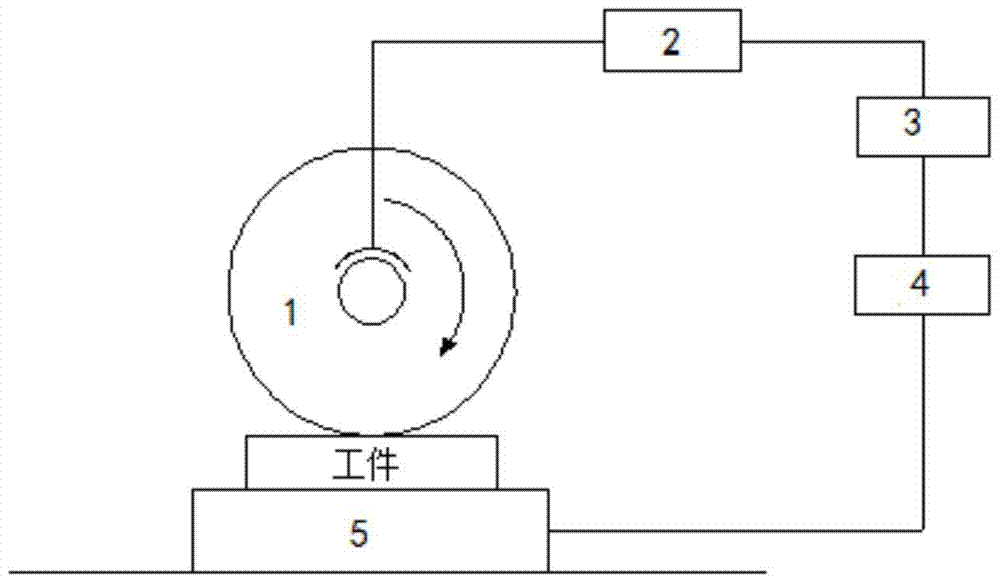

[0026] Such as figure 1 As shown, the present invention provides a controllable fast reciprocating point feed grinding system based on the grinding temperature empirical model. The grinding system includes a high-speed grinding wheel spindle system 1, a spindle power signal real-time acquisition and processing system 2, and an expert database system 3 , CNC control system 4 and fast reciprocating point feed table 5.

[0027] During grinding, the high-speed grinding wheel spindle system 1 drives the grinding wheel to rotate at high speed to grind the workpiece; at the same time, the spindle power signal re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap