Dynamic and static ring structure of molded pulp rotating hub machine

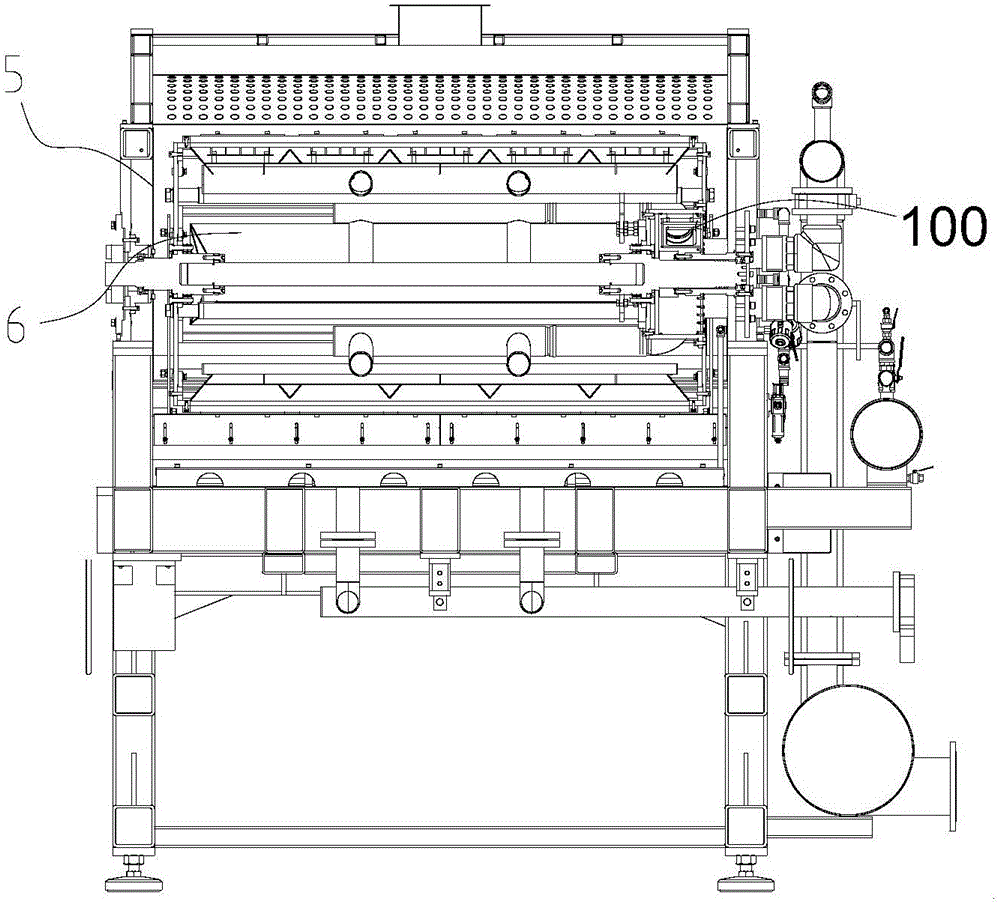

A pulp molding, dynamic and static ring technology, applied in textiles and papermaking, etc., can solve the problems of easy plane wear, unstable air pressure, large fluctuations, etc., and achieve the effect of good sealing and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

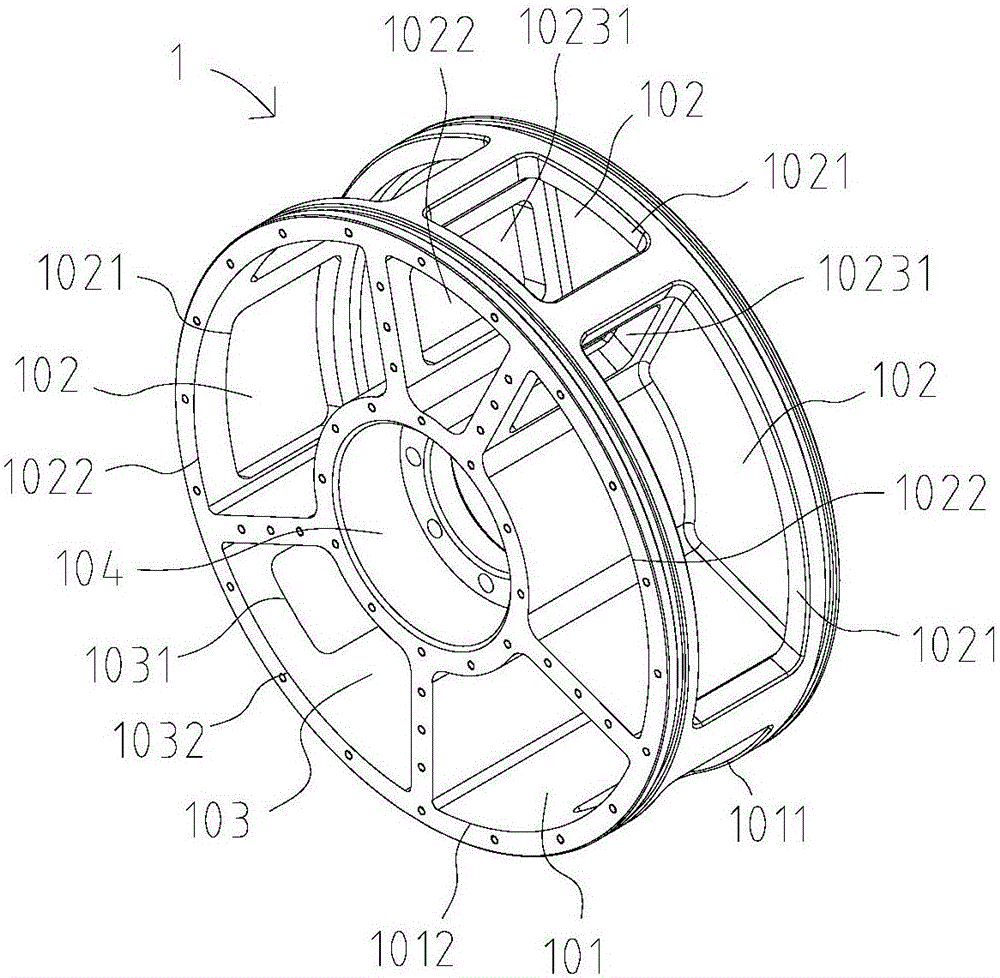

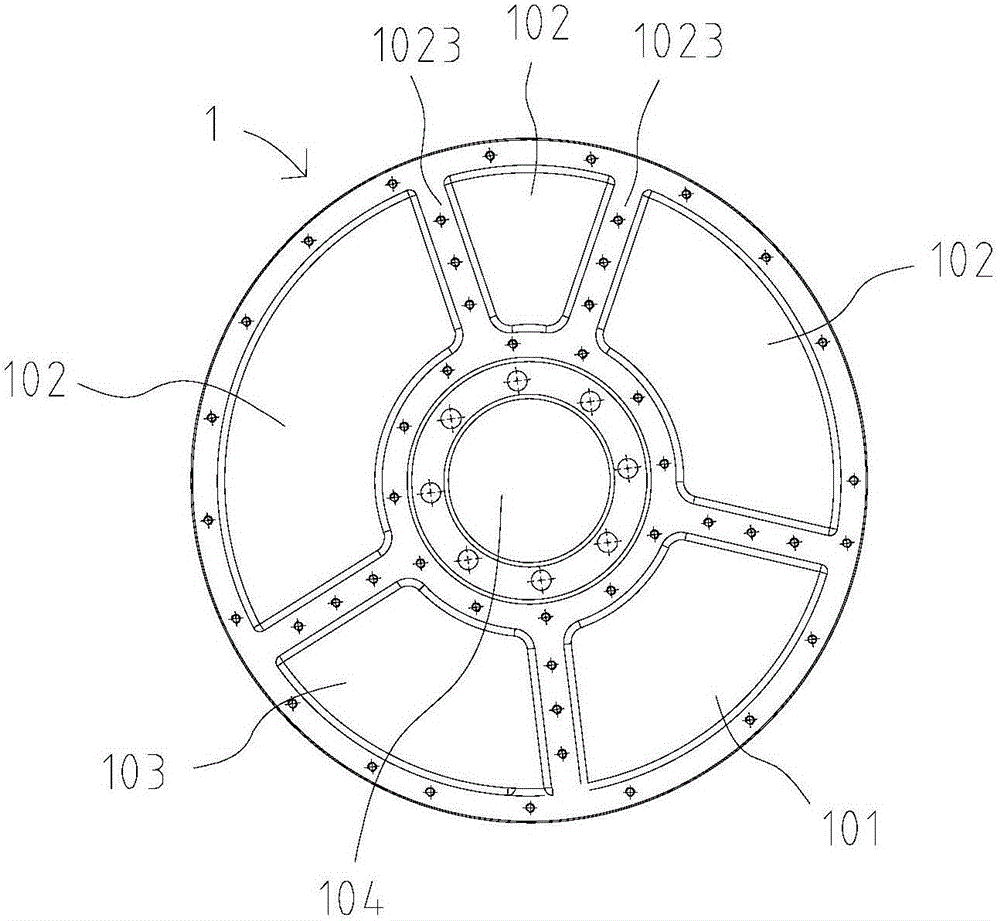

[0025] The technical scheme of the present invention is illustrated below in conjunction with accompanying drawing:

[0026] see Figure 2 to Figure 7 , the dynamic and static ring structure 100 of the pulp molding rotary hub machine of the present invention includes a dynamic ring body 2 and a static ring body 1, a first connecting shaft hole 104 is provided in the middle of the static ring body 1, and a first connecting shaft hole 104 is arranged in turn around the first connecting shaft hole 104. There are slurry suction air chamber 101, dehydration air chamber 102 and blowing air chamber 103, and the moving ring body 2 is provided with an air flow channel 202 and a second connecting shaft hole (not shown in the figure), and the moving ring body 2 can be opposite to the static ring The body 1 rotates, and the air flow channel 202 is switched to communicate with the above three air chambers in sequence; the static ring body 1 is columnar, and the slurry suction chamber 101, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com