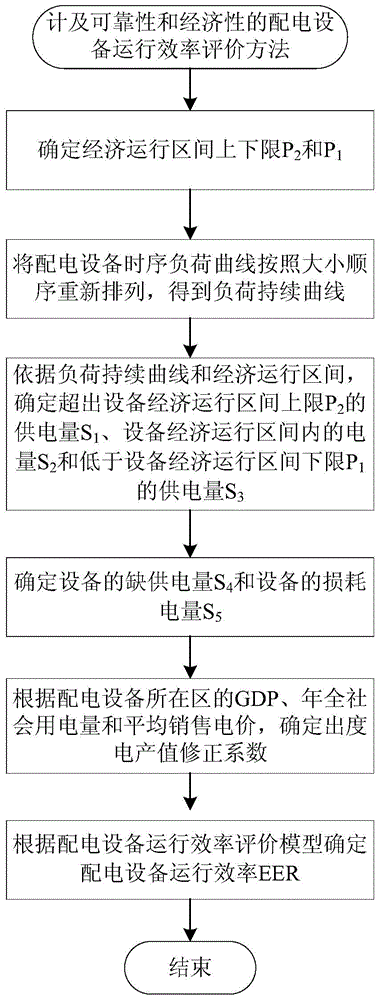

Distribution equipment operation efficiency evaluation method involving reliability and economy

A technology for power distribution equipment and operation efficiency, applied in computing, data processing applications, system integration technology, etc., can solve the problems such as the overall situation that cannot accurately reflect the dynamic change of the operation efficiency of the distribution network, and achieve accurate and objective equipment operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

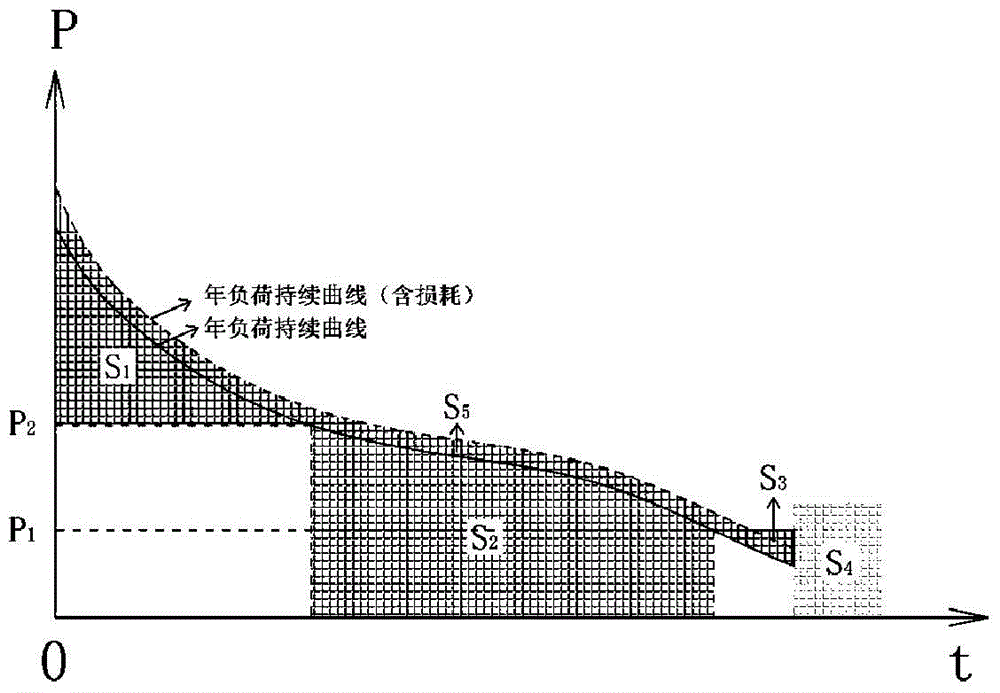

Method used

Image

Examples

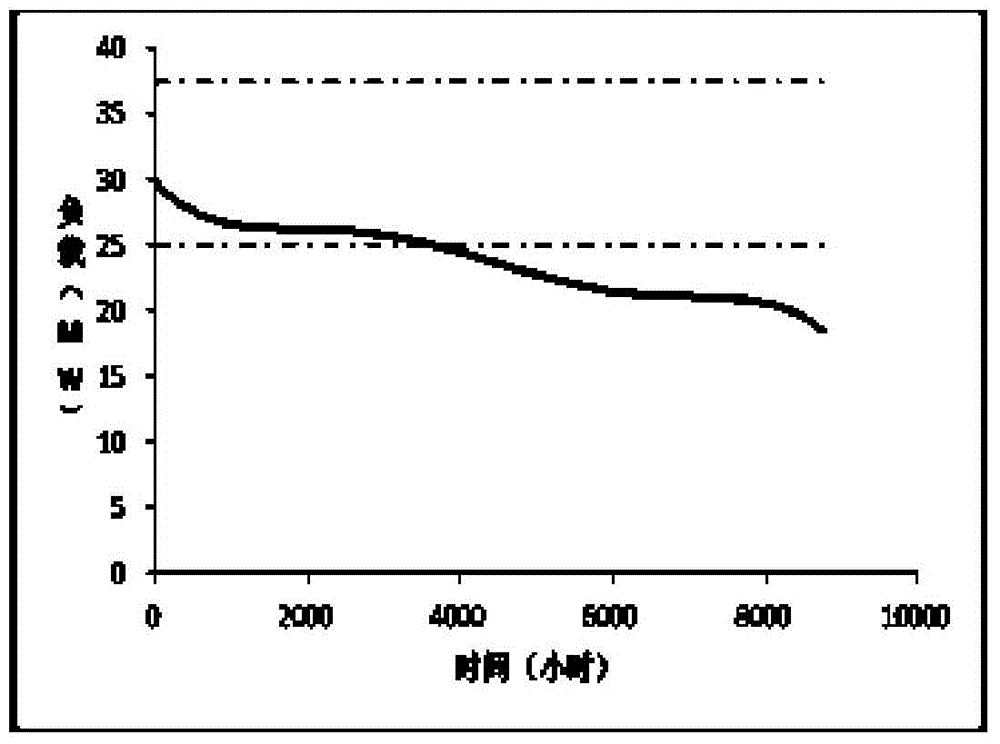

Embodiment

[0056] Taking 110kV transformer A and 110kV transformer B as examples, the calculation data of transformer operating efficiency (EER) are shown in Table 1 below.

[0057] Table 1 Transformer operating efficiency (EER) calculation related data

[0058]

[0059] According to the implementation steps of the present invention, the operating efficiencies (EER) of 110kV transformer A and 110kV transformer B are 0.7972 and 0.7211 respectively, see Table 2 below.

[0060] Table 2 Operation Efficiency (EER) of 110kV Transformer A and 110kV Transformer B

[0061] transformer name

[0062] The invention comprehensively considers factors such as safety and reliability, economical operation, utilization rate and duration, and can more comprehensively evaluate the operation efficiency of the power distribution equipment in the full time domain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com