Ventilation mattress

A technology of mattresses and cushion cores, applied in the field of ventilated mattresses, can solve problems such as inability to effectively generate airflow layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

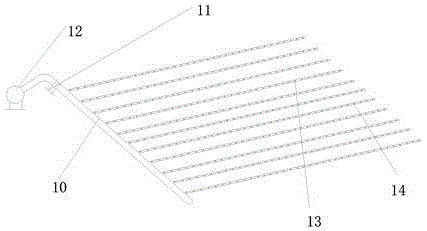

[0018] A ventilated mattress, including a cushion core and a cushion cover, is characterized in that a thicker air guide tube sealed at the far end is arranged on the upper side of the cushion core, and a number of thin and soft air vent tubes with a plurality of air holes evenly distributed therein and the air guide tube The trachea is connected and distributed in a grid pattern in the cushion core; the pores on the trachea are upward and arranged in rows, and the pore diameter is 100 nanometers; an air inlet is provided at the non-sealed end of the air guide tube, and the air intake tube It is connected to the compressed air bag through the control of the intake valve; the intake valve is controlled in multiple stages according to the intake flow rate, and the intake rate can be adjusted through the intake valve to adjust the air flow rate on the mattress; it is made of a material with good air permeability The finished cushion cover wraps the cushion core; when in use, open ...

Embodiment 2

[0020] A kind of ventilated mattress, comprising a cushion core and a cushion cover, characterized in that the air guide tube is arranged on the cushion core, and the air guide tube surrounds the surrounding edges arranged on the above cushion core, and the two ends are connected; several uniform The two ends of the thin and soft trachea with a plurality of air holes are respectively connected with the air guide tube, and are distributed in a grid shape in the cushion core; the pores on the trachea tube are opened upward and arranged in rows, and the pore diameter is 200 nanometers; in the air guide tube There is an air inlet on the top, and the air inlet is set at a corner of the air guide pipe; the air inlet pipe is controlled by the air inlet valve and connected to the compression fan; the air inlet valve is controlled in multiple stages according to the air intake flow, and through The air valve can adjust the air intake to adjust the air flow on the mattress; the cushion c...

Embodiment 3

[0022] A ventilated mattress, including a cushion core and a cushion cover, is characterized in that a thicker air guide tube sealed at the far end is arranged on the upper side of the cushion core, and a number of thin and soft air vent tubes with a plurality of air holes evenly distributed therein and the air guide tube The trachea is connected and distributed in a grid pattern in the cushion core; the pores on the trachea are upward and arranged in rows, and the pore diameter is 100 nanometers; an air inlet is provided at the non-sealed end of the air guide tube, and the air intake tube It is connected to the compressed air tank through the control of the intake valve; the intake valve is controlled in multiple stages according to the intake flow, and the intake volume can be adjusted through the intake valve to adjust the air flow on the mattress; An air heating device is installed on the inner side. When using in cold weather, turn on the air heating device to moderately h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com