Method for determining time of tool changing based on dynamic reliability

A technology of tool change time and reliability, applied in the field of determining tool change time and determining tool change time based on dynamic reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

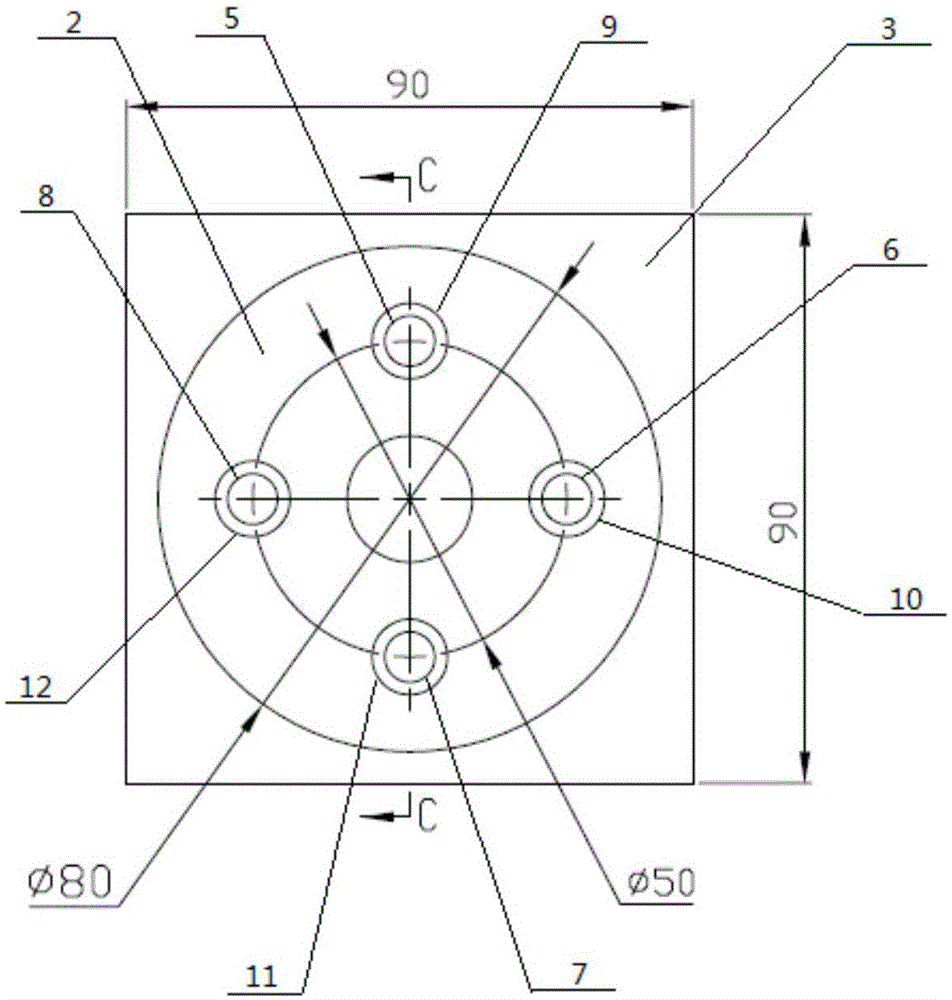

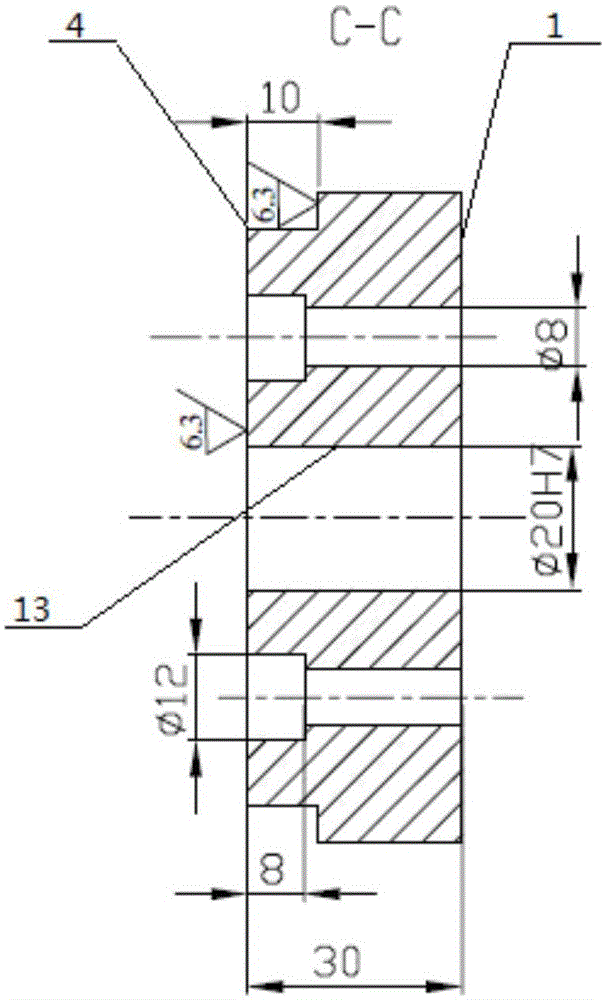

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] The method for determining the tool change time based on the dynamic reliability of the present invention is specifically implemented according to the following steps:

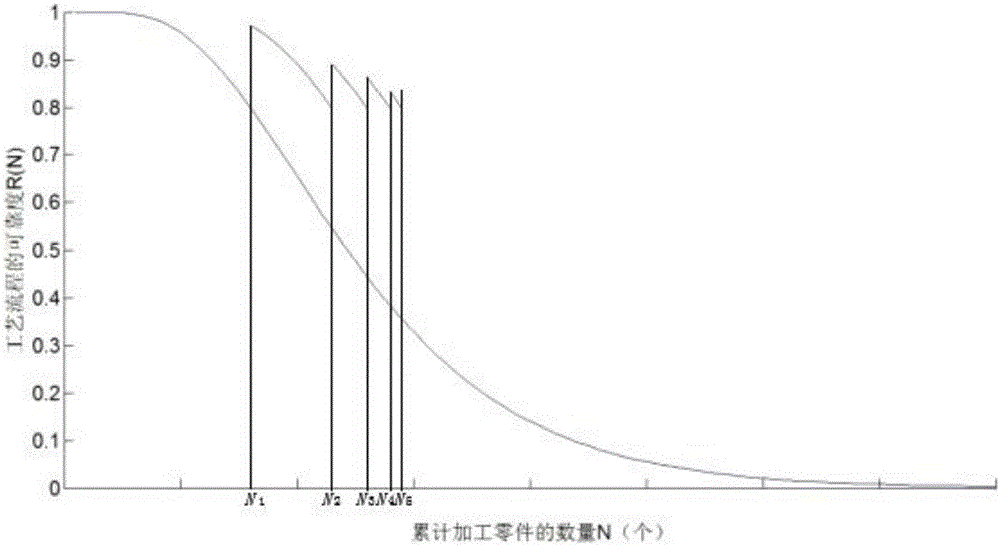

[0054] Step 1, establish the dynamic reliability model of the whole process flow

[0055] When processing parts, the machine tool, operator, and tool form a series system and are independent of each other, then the reliability of the entire process flow is expressed as:

[0056] R b (t)=R m (t)×R o (t)×R t (t)(1)

[0057] In the formula, R b (t), R m (t), R o (t), R t (t) represent the reliability of the overall process, machine tool, operator and tool respectively;

[0058] Assuming that when the machine tool is processing a batch of parts, the machine tool itself and the operator do not fail, that is, R m (t)=R o (t)=1, then there is

[0059] R b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com