Stepless speed change device and application thereof

A technology of continuously variable speed change device and speed change gear, which is applied in the direction of vehicle gearbox, wheel drive device, transportation and packaging, etc., can solve the problems of chain twist, chain jam, production quality fluctuation, etc., to overcome the unstable speed change, control Simple, comfort-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

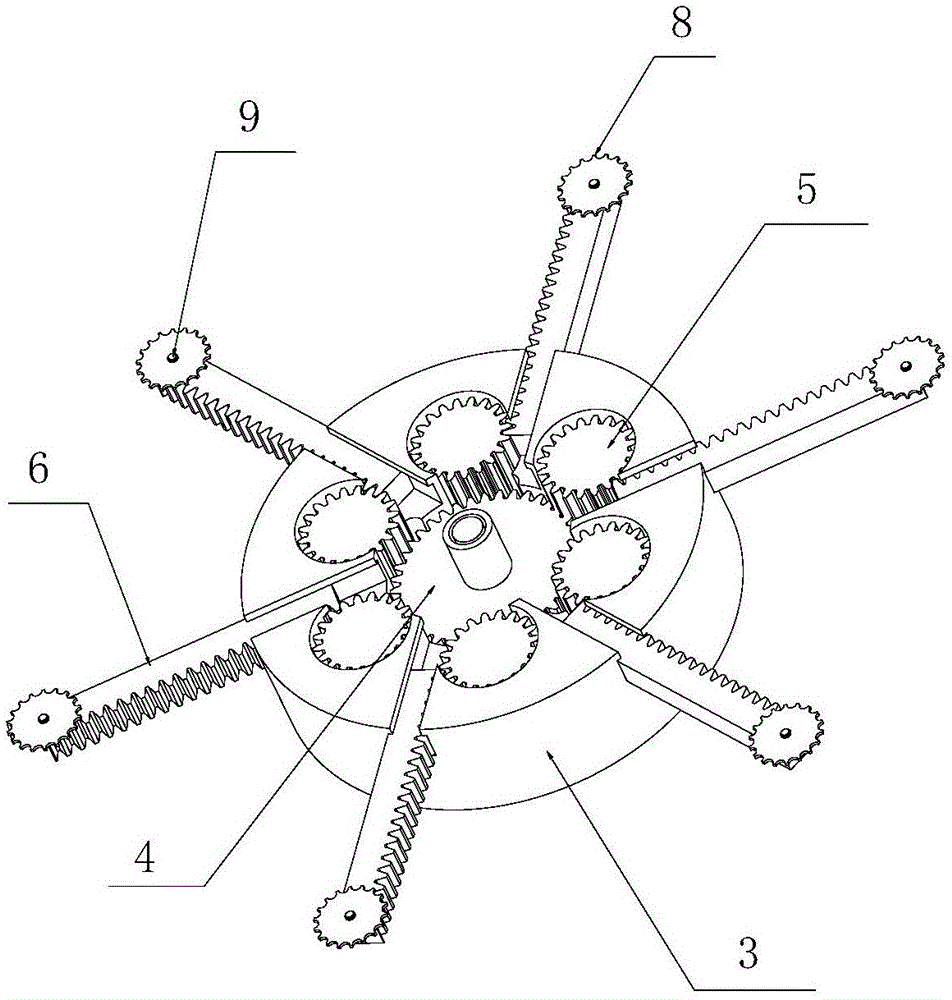

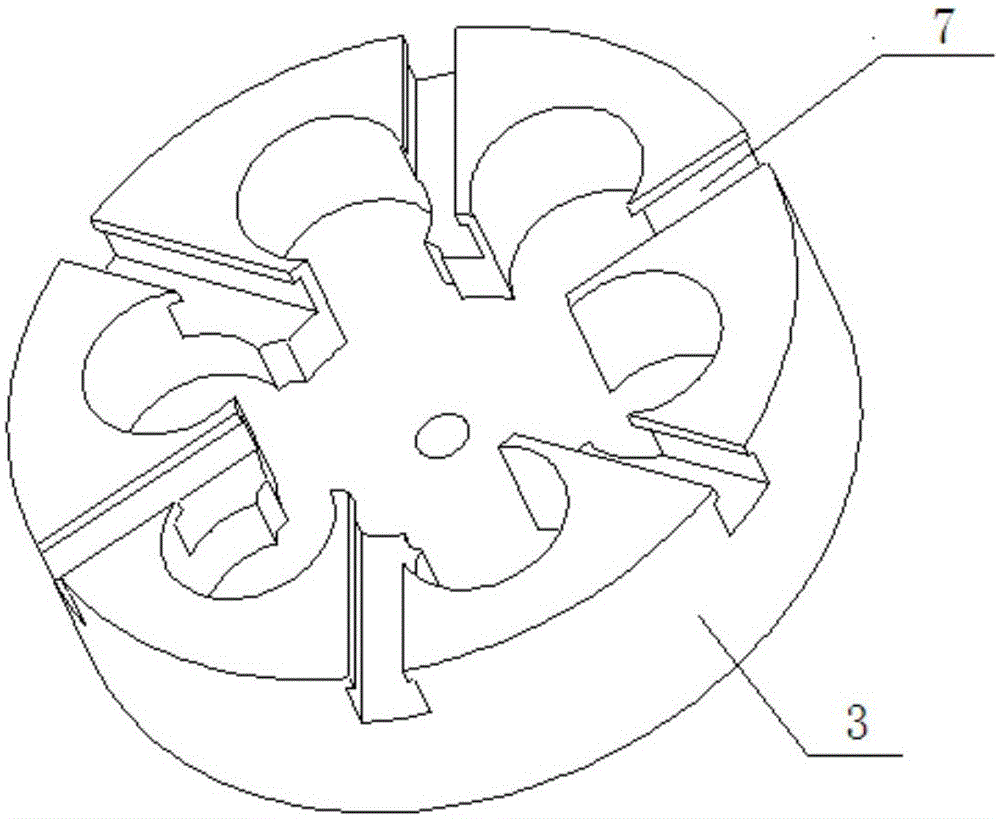

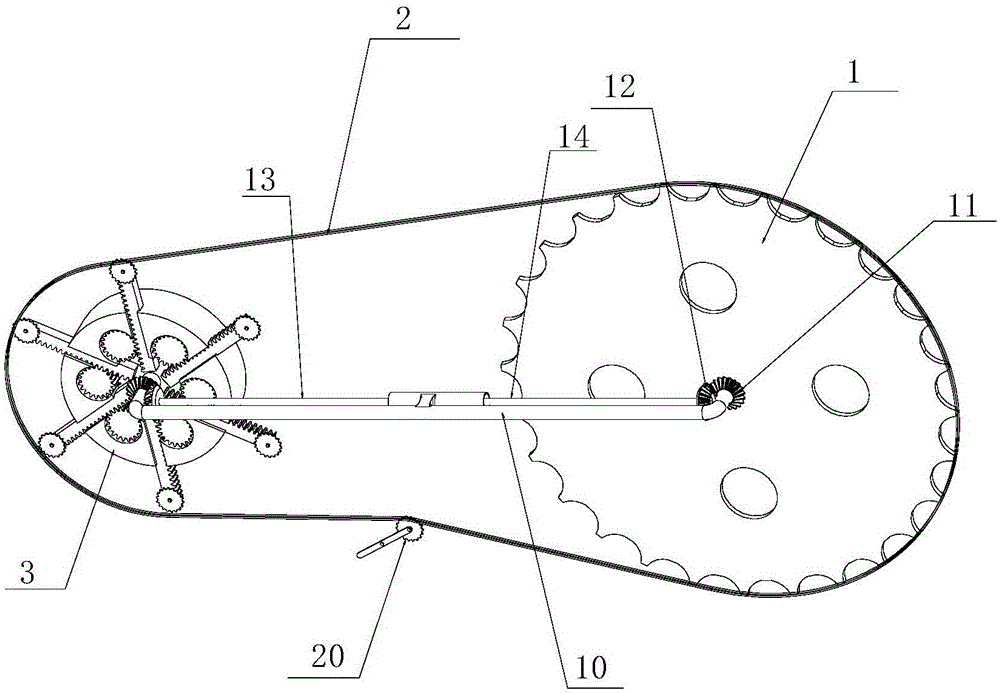

[0035] refer to image 3 , the above-mentioned continuously variable transmission device is applied to the bicycle, the left side is the continuously variable transmission device, which is installed on the rear wheel and is coaxial with the rear wheel, and is used to replace the transmission device of the existing variable speed bicycle; the right side is the drive sprocket 1 , same as existing bicycle, chain 2 passes tension wheel 20 around it. The large gear 4 is connected with the driving sprocket 1 through the control rod, the rotation of the large gear 4 drives the pinion 5, and the rotation of the pinion 5 drives the shift rack 6 to move back and forth, so as to realize the overall expansion and contraction of the shift rack 6, thereby achieving the purpose of changing the diameter of the transmission .

[0036] For details on the control section, see Figure 4 , Figure 5 and Figure 6 , the middle part of the control rod is fixed on the frame 10, the two ends of th...

Embodiment 2

[0043] Apply this continuously variable transmission device to industry, such as Figure 7 and Figure 8 As shown, two sets of continuously variable transmission devices are adopted, and a transmission chain or a transmission belt 17 can be used to bypass the sprocket disc or small pulley 8 of the continuously variable transmission device. Two sets of continuously variable transmission devices are installed on the same frame 10, and the front and rear axes are arranged horizontally; the large gears 4 of the two sets of continuously variable transmission devices are respectively connected with the front speed regulating motor 18 and the rear speed regulating motor 19. The two motors drive the internal large gear 4 to rotate through rotation, so as to realize speed change.

[0044] When driving normally, the two motors do not work, that is, the transmission device does not work;

[0045] When the transmission ratio needs to be increased, the rear speed-regulating motor 19 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com