Connection node structure of fair-faced concrete prefabrication exterior wall hanging plates

A technology of fair-faced concrete and connecting nodes, which is applied in the direction of building structure, covering/lining, construction, etc., can solve the problems of damage and falling off, failure to install, and large internal force of hanging boards, etc., to achieve convenient on-site operation and ensure mobility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

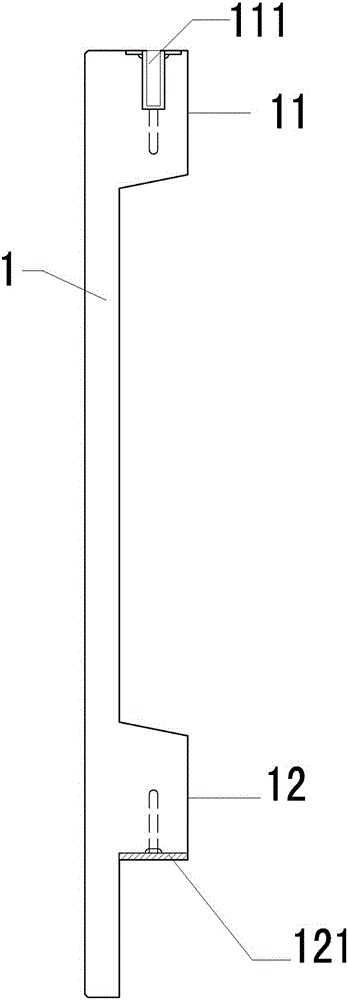

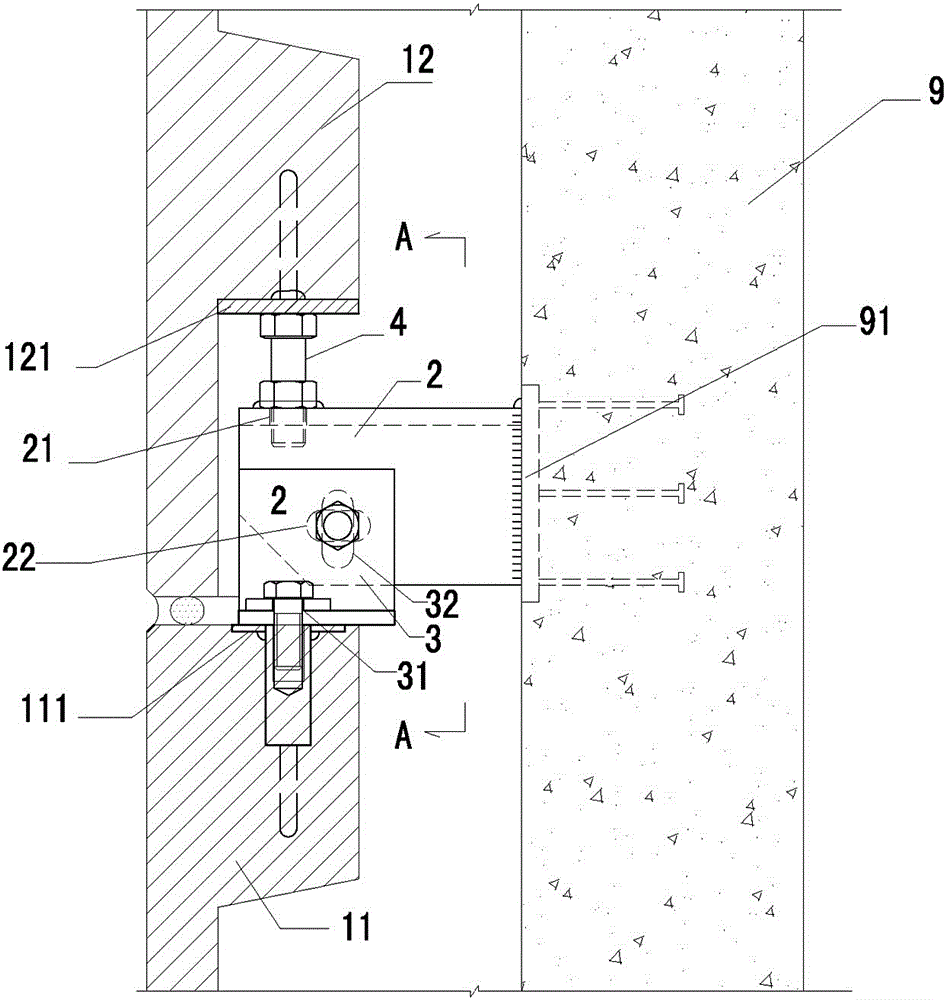

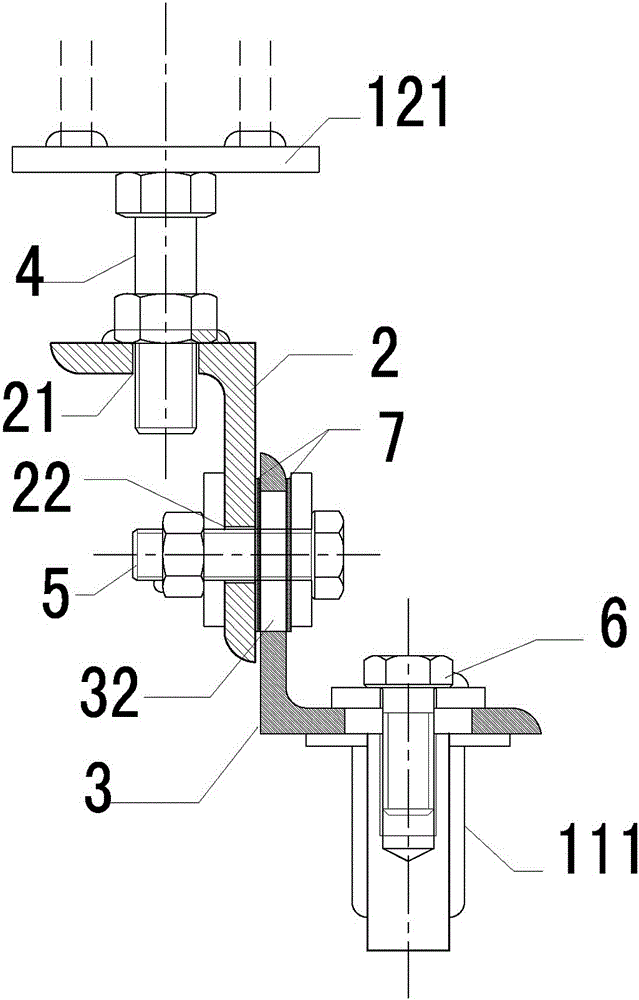

[0016] Such as Figure 1-3 As shown, a clear-water concrete prefabricated exterior wall hanging panel connection node structure, the exterior wall hanging panel 1 has an upper corbel 11 and a lower corbel 12, and a pre-embedded nut 111 is arranged on the top of the upper corbel, and a built-in nut 111 is arranged on the lower corbel The lower part is provided with a pre-embedded steel plate 121; the connection node structure includes the first connection angle steel 2, the second connection angle steel 3 and the support bolt 4; the first connection angle steel 2 is welded and fixed to the pre-embedded base 91 in the main frame structure , the first circular through hole 21 is opened on the horizontal side of the first connecting angle steel, the first elongated through hole 22 is opened on the vertical side, and the second connecting angle steel 3 is opened on the horizontal side The circular through hole 31 has a second elongated through hole 32 on the vertical side; the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com