Automatic pencil sharpener

A mechanical pencil and automatic technology, applied in printing, office supplies, sharpening devices, etc., can solve problems such as inconvenient use, and achieve the effect of avoiding the problem of switch connection and solving the problem of switch connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

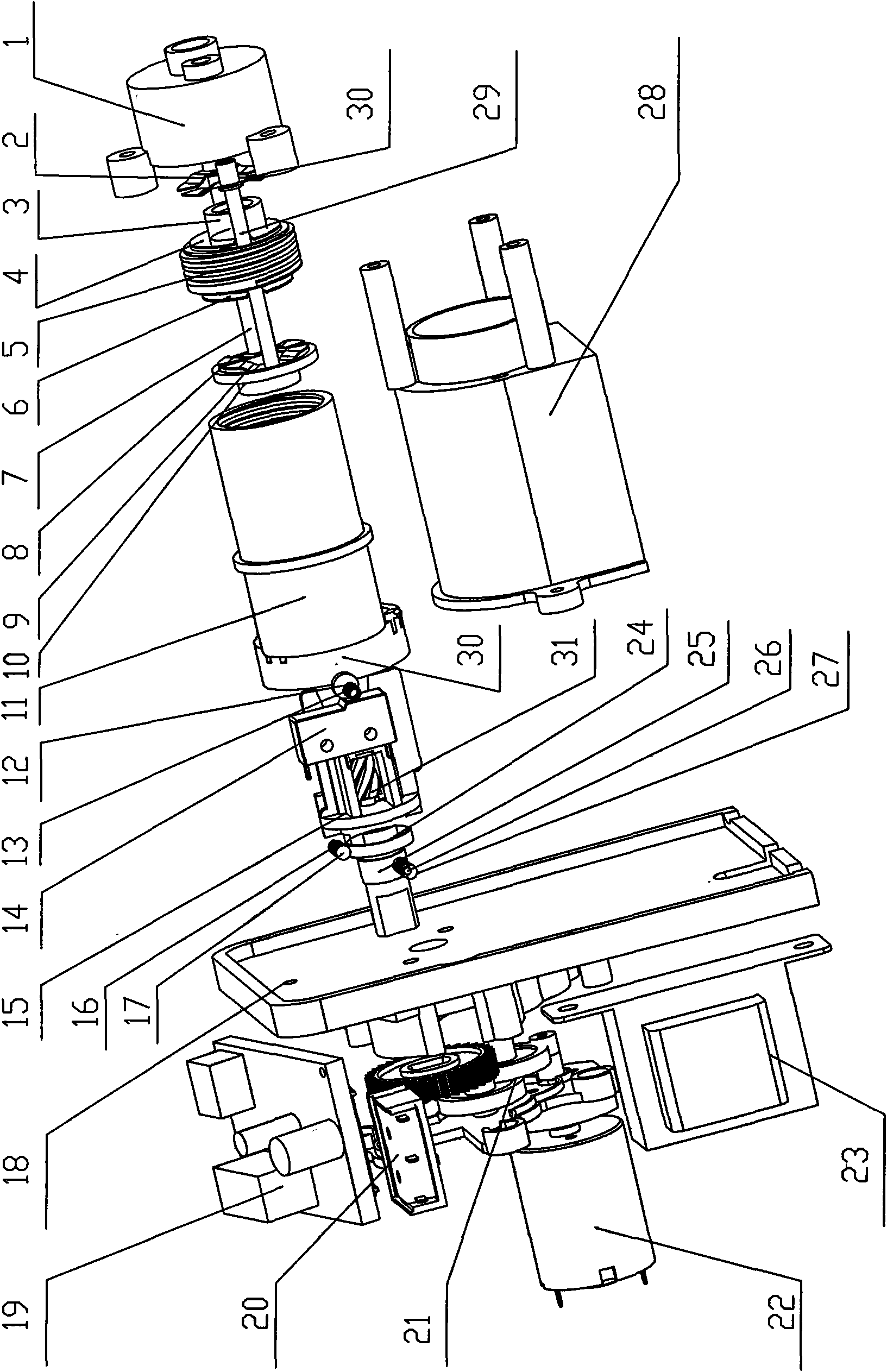

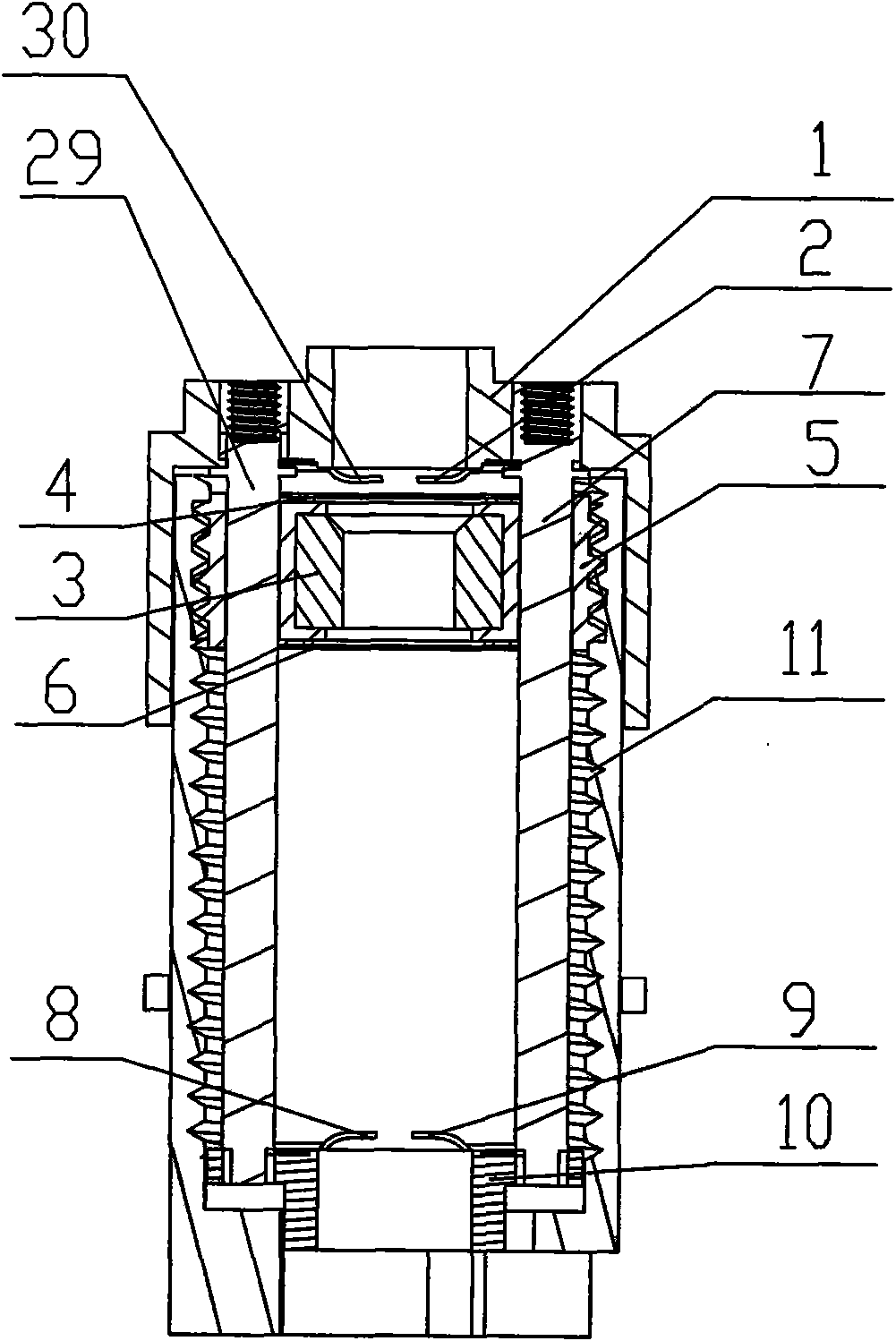

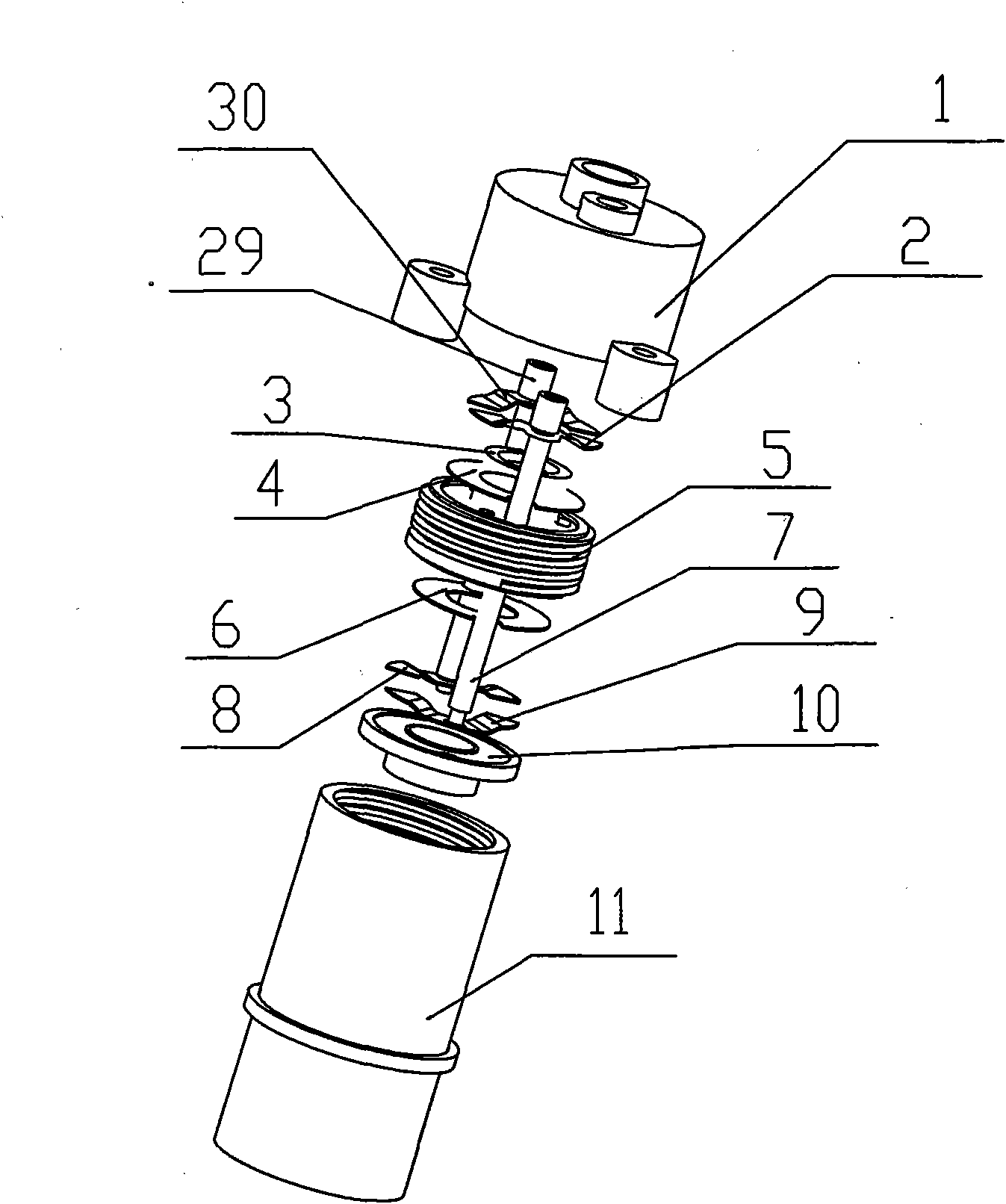

[0014] An automatic pencil sharpener includes a motor 22, a transmission mechanism driven by the motor 22, an automatic cutting mechanism, an automatic advance and retreat pen mechanism, and a slip ring reversing mechanism.

[0015] refer to figure 1 , the transmission mechanism driven by the motor 22 includes a fire cow 23, an electronic board 19, a gear set 21, a bracket 18, a knife rest 15, a screw sleeve 11, and a movable stud 5. The motor 22 drives the gear set 21, and the knife rest 15 is socketed on the final gear of the gear set 21, and the knife rest 15 is connected to the screw sleeve 11 simultaneously, so that the movable stud 5 moves back and forth under the drive of the screw sleeve 11. The movable stud 5 is provided with a through hole, which is the entrance of the pencil cutting movement.

[0016] refer to figure 1 and Figure 4 , the automatic cutting mechanism includes a tool holder 15 , a hob 31 , and a ring gear 30 . The hob 31 and the knife rest 15 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com