Laying method for large-aperture water draining pipeline parallel to upper part of existing metro tunnel structure

A technology with existing subway and tunnel structures, applied in the sewer system, waterway system, water supply device, etc., it can solve the problems of cracking and leakage of the tunnel structure, large surrounding land subsidence, and displacement of the tunnel structure, reducing the excavation space, The effect of reducing space occupation and small hoisting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

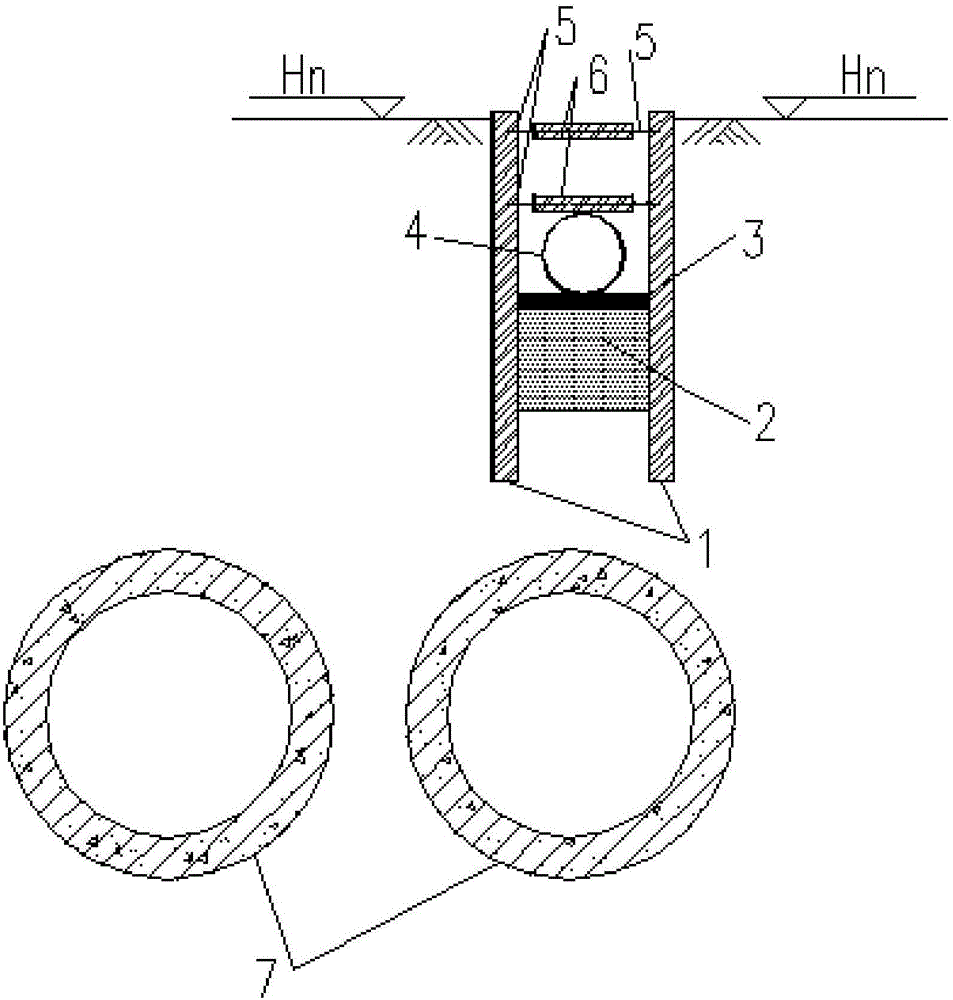

[0028] Such as figure 1 As mentioned above, the present embodiment proposes a method for laying large-diameter drainage pipes parallel to the existing subway tunnel structure, which method includes the following steps:

[0029] Step 1: Using the mixture 2 of cement and water glass, the bottom of the trench is reinforced through a layered grouting process. In the mixture of cement and water glass, the mixture of fresh ordinary Portland cement (cement strength grade 42.5) and water glass is used, and the cement dosage and water-cement ratio should be determined according to field tests. However, the components of the mixture should meet the following conditions at the same time: the grouting volume ratio is greater than or equal to 20%, the water-cement ratio is 0.5, the cement to water glass volume ratio is 1:1, and the water glass modulus is 3.0 to 3.3.

[0030] The cement and water glass mixture layered grouting reinforces the soil at the bottom of the trench, increases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com