A Maintenance and Drainage System for V-shaped Tailrace Tunnels

A tailrace tunnel and drainage system technology, which is applied in water conservancy projects, hydroelectric power generation, hydropower stations, etc., can solve problems such as increased construction costs, large displacement, and complicated processes, and achieves shortened length of drainage pipelines, reduced excavation space, and Ensure the effect of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

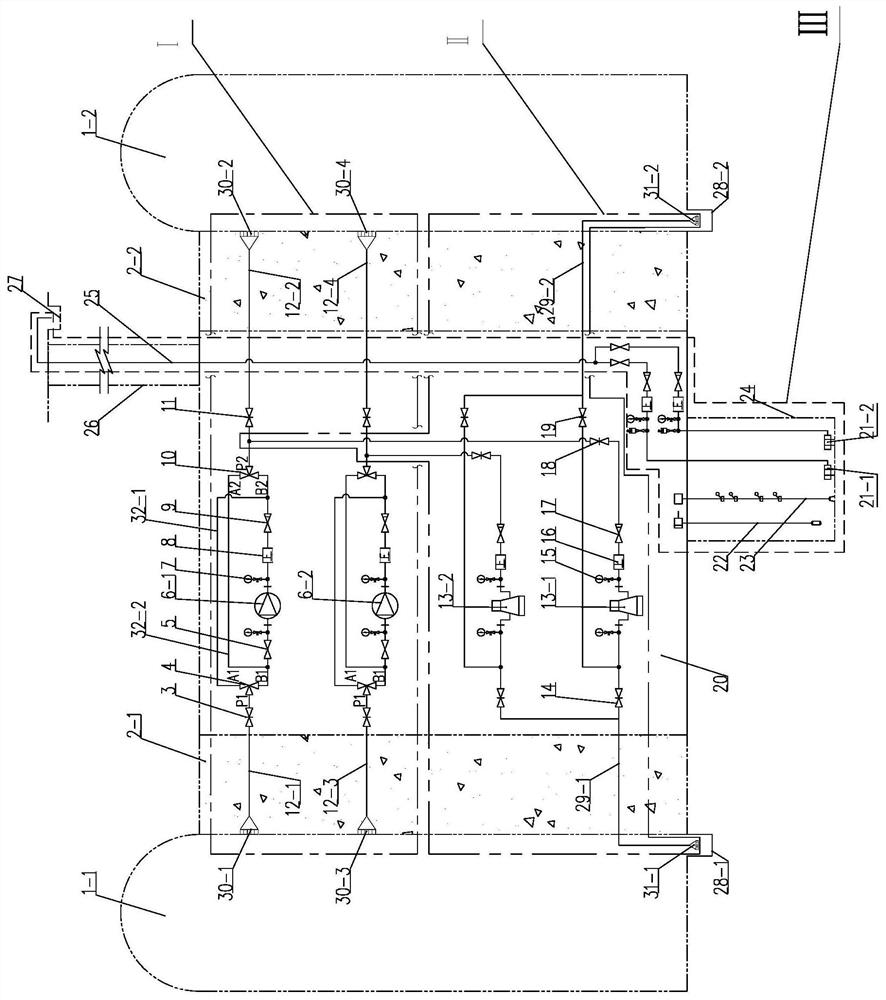

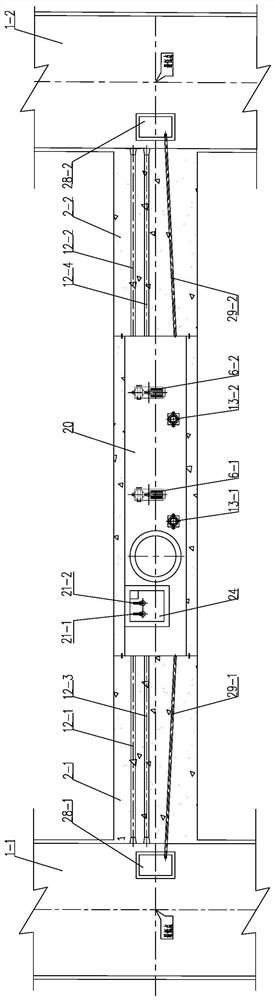

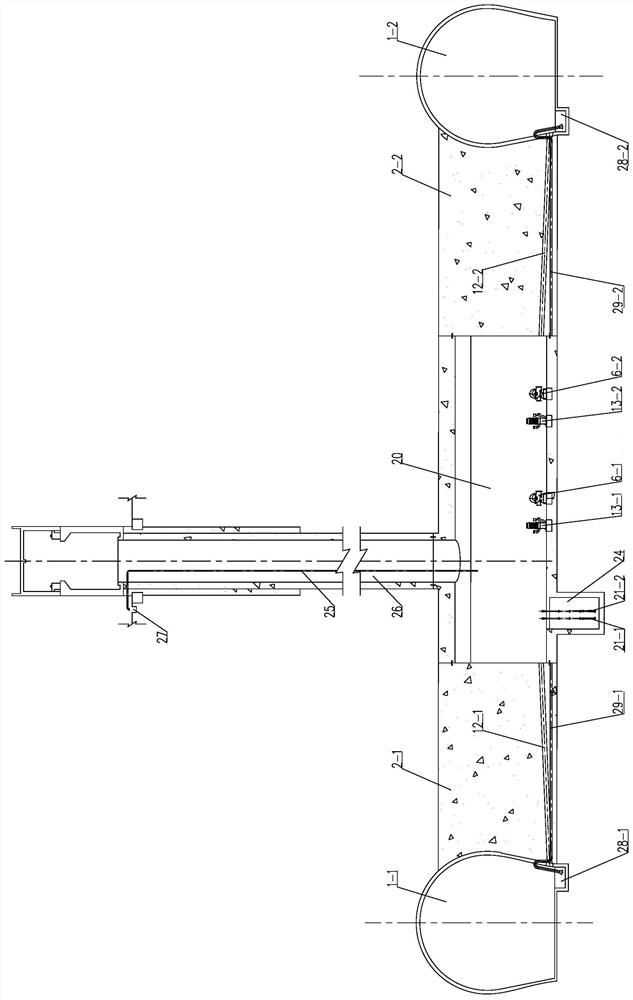

[0030] like figure 1 As shown, this embodiment is a diagram of the maintenance and drainage system applied to the V-shaped tailwater tunnel group of a certain hydropower station. figure 2 It shows the plane layout of civil works and main equipment pipelines of this embodiment, image 3 The section layout of civil works and main equipment pipelines of this embodiment is shown.

[0031] The power station has two tailwater tunnels 1-1 and 1-2. The drainage pump house 20 is located between the two tailrace tunnels. The sump 28-1 and 28-2 are respectively excavated at the lowest points of the two tailrace tunnels.

[0032] Two sets of main pump drainage systems and two sets of self-priming pump drainage systems are set up for maintenance drainage system. Two main pumps 6-1 and 6-2, two self-priming pumps 13-1 and 13-2 are installed in the drainage pump room.

[0033] Between the two tailrace tunnels 1-1, 1-2 and the pump house 20, the sealing bodies 2-1 and 2-2 are placed res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com