An integrated structure and construction method of foundation pit support of urban underground comprehensive pipe gallery and external formwork of underground structure

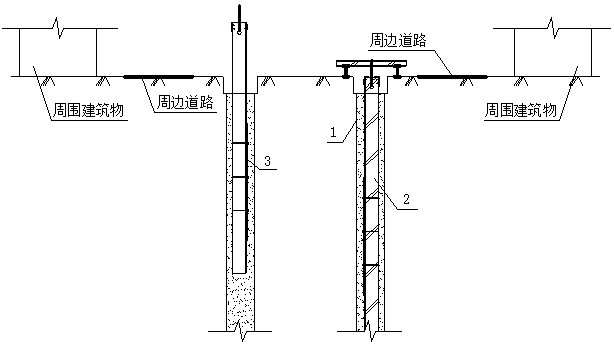

A technology that integrates pipe galleries and underground structures. It is used in infrastructure engineering, underwater structures, and excavation. It can solve the problems of reducing excavation space, occupying more width of municipal roads, and limited working space for open-cut excavation. The effect of reducing the excavation space and having little impact on the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

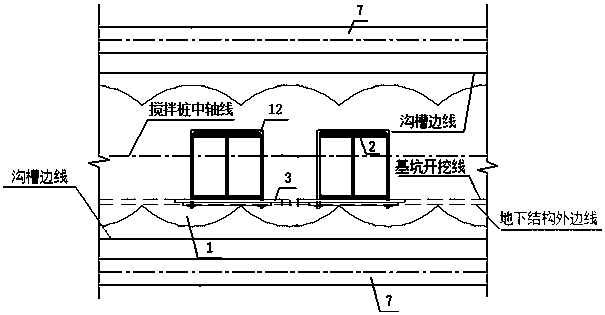

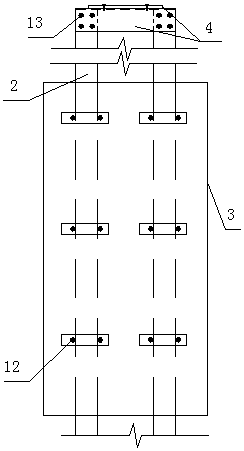

[0052] Embodiment 1: As shown in the figure: according to the conditions of the surrounding roads and surrounding buildings, the comprehensive pipe gallery 11 with a cross-sectional size of 3000×4200mm is constructed by the open cut method. The buried depth of the bottom plate is 7m, and the soil condition is clay. C40 reinforced concrete with impermeability level of P6 uses HRB400 steel bars with a diameter of 12mm. Cushion 14 adopts 100mm thick C20 plain concrete. First, install the HDPE material formwork 3 of 3200×1500×20mm on two interpolated steels 2 arranged at a distance of 800mm. The formwork and the interpolated steels are connected by U-shaped bolts 12 with a diameter of 18mm. The U-shaped bolts use 10mm pads. plate; and then the tool piece is connected to the top of the two interpolated section steel 2 by bolts 13, forming a component unit at this time. Among them, the inserted section steel 2 adopts the type 40 inserted I-beam with a length of 8m; the tool part 4 ...

Embodiment 2

[0053] Example 2: As shown in the figure: the comprehensive pipe gallery with a section size of 3000×3000mm is constructed by the open cut method, the depth of the bottom plate is 6m, the soil condition is muddy soil, and C40 reinforced concrete with an impermeability grade of P8 is used in the design , which uses HRB400 steel bars with a diameter of 12mm. Cushion 14 adopts 100mm thick C20 plain concrete. Firstly, the formwork 3 of 3200×1500×20mm steel material is installed on two interpolated steels 2 arranged at a distance of 400mm. 10mm backing plate; then the tool piece 4 is connected to the top of the two interpolated steel sections 2 through bolts 13, forming a component unit at this time. Among them, the interpolation steel 2 adopts the interpolation H-beam of model 40#, and the length is 8m; the tool part 4 adopts the angle steel of 200×125×12mm and the steel plate of 500×800×20mm. Repeat the above process to complete all the component units required for construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com