Construction method of shaft antiseep structure used when large section of inclined shaft passes through aquifer

A construction method and large-section technology, applied in wellbore lining, shaft equipment, earthwork drilling, etc., can solve the problems of high cost, long construction period, insufficient wellbore anti-seepage measures, etc., to improve project quality, low cost, reduce The effect of excavating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

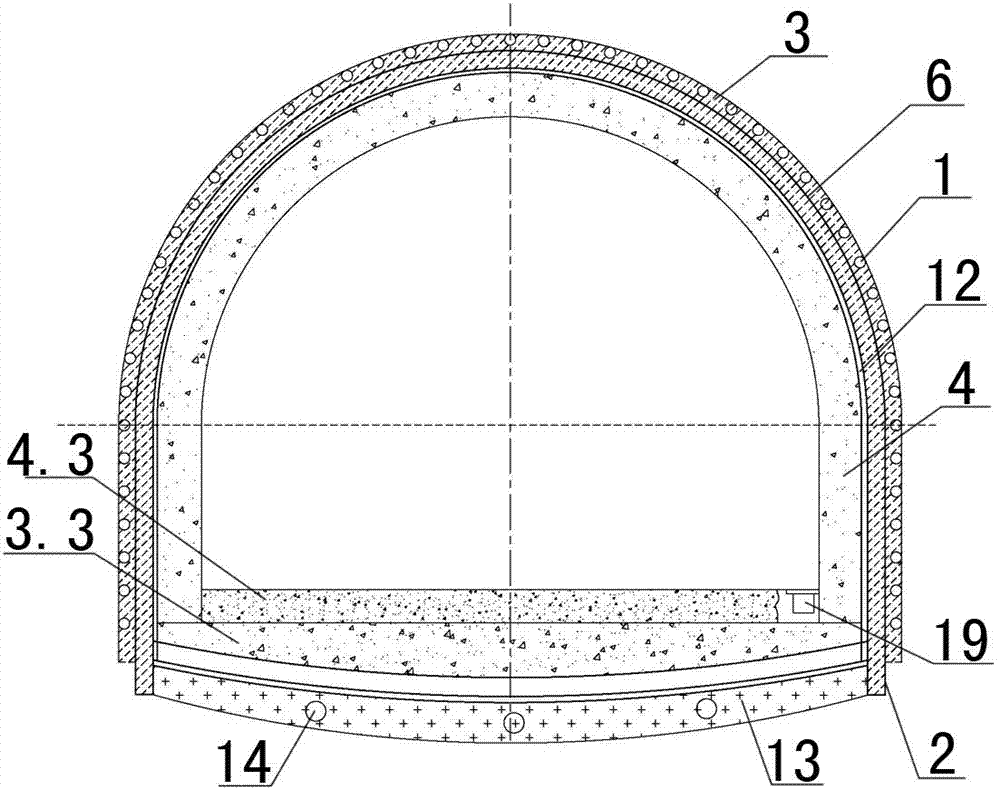

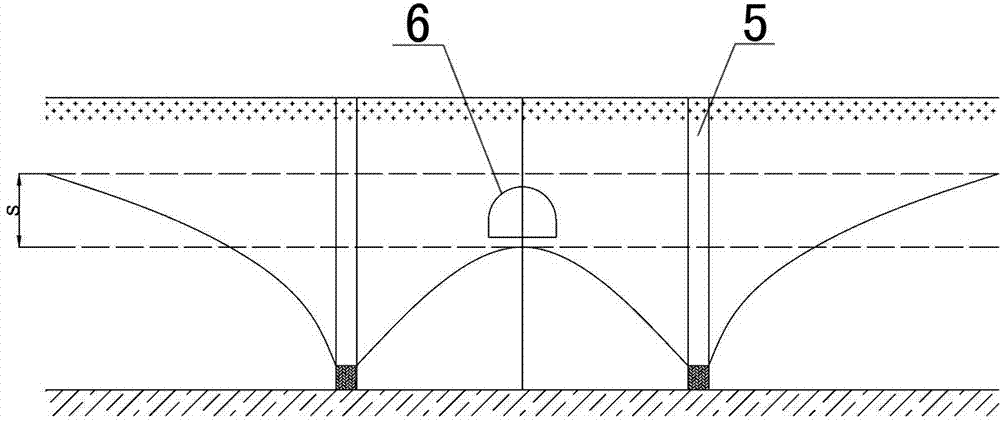

[0063] Examples see figure 1 As shown, an anti-leakage structure of an inclined shaft with a large cross-section passing through an aquifer wellbore is a multi-layer support structure of a mine roadway 6, including initial support and permanent support. The initial support includes a steel pipe shed 1, a steel support 2 and initial support concrete 3, the profiled steel support 2 is composed of arch support 2.1, left wall support 2.2, right wall support 2.3 and reverse arch support 2.4, and the initial support concrete 3 is composed of arch ring shotcrete 3.1, edge Wall shotcrete 3.2 and anti-arch cast-in-place concrete 3.3,

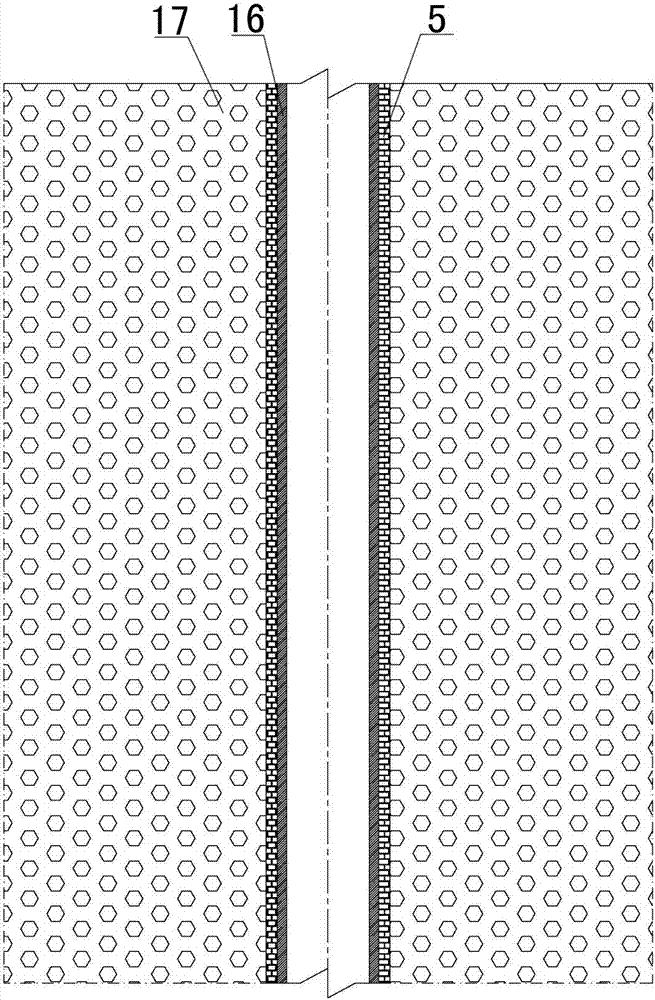

[0064] Between the initial support and the permanent support of the arch and the side wall, an arch water-resisting layer 12.3 and a side wall water-resisting layer 12.2 are respectively provided, and the lower side of the anti-arch support 2.4 is provided with a water-filtering layer and a water-repelling layer from bottom to top. Anti-arch water-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com