A continuous negative pressure sand pumping string with concentric tubing for horizontal wells

A technology for process strings and horizontal wells, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of low flowback rate, large amount of liquid entering the ground from medium and low pressure oil, and affect the development effect of horizontal wells and other issues to achieve the effect of improving construction efficiency and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

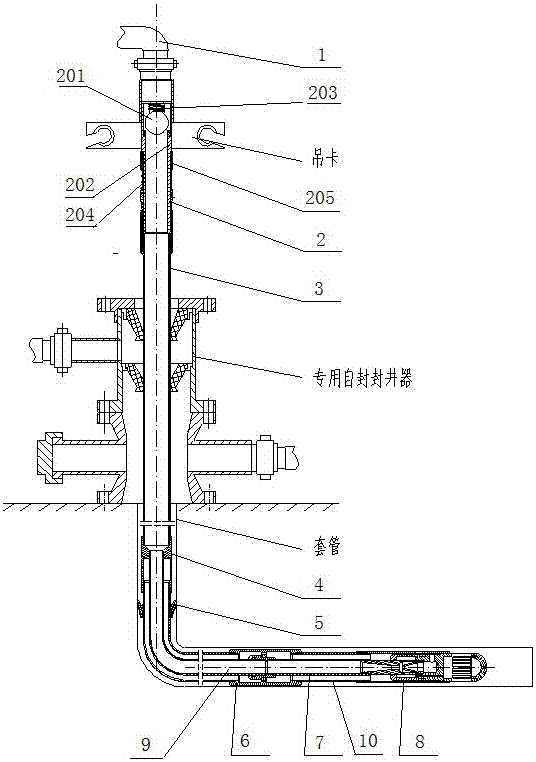

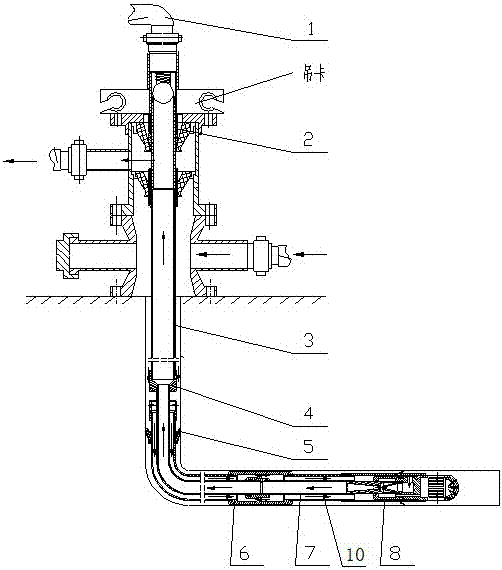

[0027] This embodiment provides a horizontal well concentric tubing continuous negative pressure sand pumping process string, such as figure 1 or figure 2 As shown, it includes a high-pressure faucet 1, a reversing joint 2, a tool oil pipe 3, a concentric oil pipe combination 9 and a negative pressure sand extractor 8. The high-pressure faucet 1 is connected to the tool oil pipe 3 through the reversing joint 2, and the lower end of the tool oil pipe 3 passes through the conversion joint 4 Connect the concentric oil pipe assembly 9, the lower end of the concentric oil pipe assembly 9 is connected to the negative pressure sand extractor 8; the reversing joint 2 is provided with a steel ball 201 and a ball seat 202 inside, the steel ball 201 is connected to the spring 203, and the other end of the spring 203 is fixed At the position above the ball seat 202 , a discharge hole 204 is opened on the wall of the reversing joint 2 below the ball seat 202 , and a sliding sleeve 205 for...

Embodiment 2

[0032] In this embodiment, the concentric tubing assembly 9 is specifically described, which completely changes the sand removal process of the horizontal well, and adopts the process string based on the concentric tubing assembly 9 instead of the process string based on the tool tubing. The concentric tubing assembly 9 includes an outer tool tubing 10 and a built-in tubing 7 located inside the outer tool tubing 10 and concentric with it. The outer tool tubing 10 and the built-in tubing 7 are kept in a concentric state through the concentric tubing collar 6. The lower end of the tool tubing 3 passes through The conversion joint 4 is connected with the built-in oil pipe 7, and a sealing cup 5 is installed on the outer wall of the outer tool oil pipe 10.

[0033] Under the action of the sealing cup 5, the circulating liquid directly enters the annulus between the outer tool oil pipe 10 and the built-in oil pipe 7 after passing through the conversion joint 4, and then enters the n...

Embodiment 3

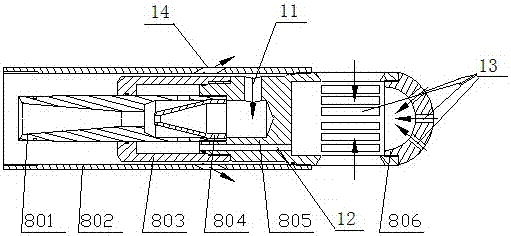

[0035] On the basis of Example 1 and Example 2, as image 3 As shown, the negative pressure sand extractor 8 in this embodiment is composed of a throat pipe 801, an outer cylinder 802, a central pipe 803, a conical nozzle 804, a connecting head 805, and a baffle head 806;

[0036] The connector 805 is a horizontal columnar structure, and its left and right surfaces are drilled with blind holes. The inner part of the blind hole on the left surface is provided with a liquid guide hole 11 along the radial direction of the columnar connector 805. The inside of the blind hole on the right surface is Along the radial direction of the cylindrical connecting head 805, there are a plurality of sand pumping channels 13, and these sand pumping channels 13 are evenly distributed in the circumferential direction of the connecting head 805, and the axial direction of the connecting head 805 is provided with a pumping channel that penetrates the connecting head 805. Sand hole 12;

[0037] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com