A method and device for realizing indoor experiment of carbon dioxide miscible flooding

A carbon dioxide and miscible flooding technology, used in earth-moving drilling, fluid production, sustainable manufacturing/processing, etc., can solve problems such as limiting the development of carbon dioxide miscible flooding experiments, reducing the minimum miscible pressure of crude oil or carbon dioxide, and difficult to achieve miscible flooding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

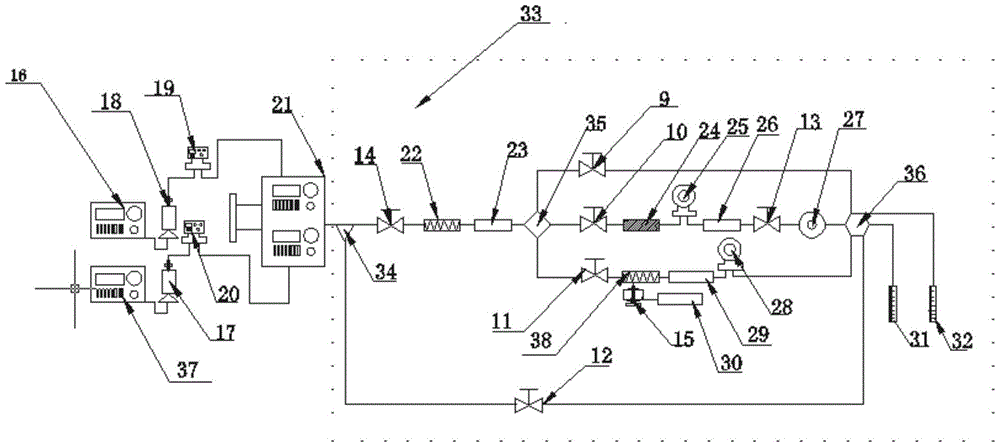

[0044] The present invention will be further described below in conjunction with accompanying drawing:

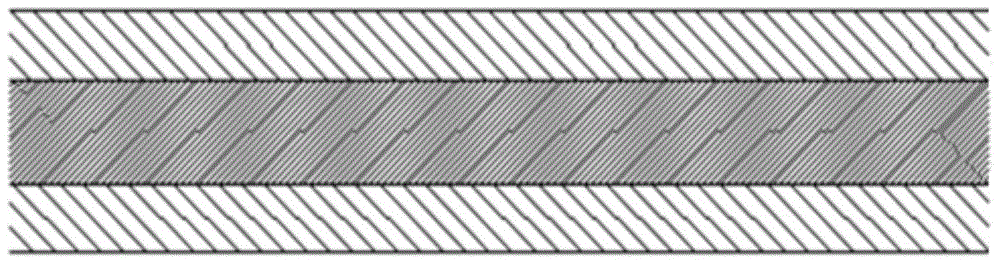

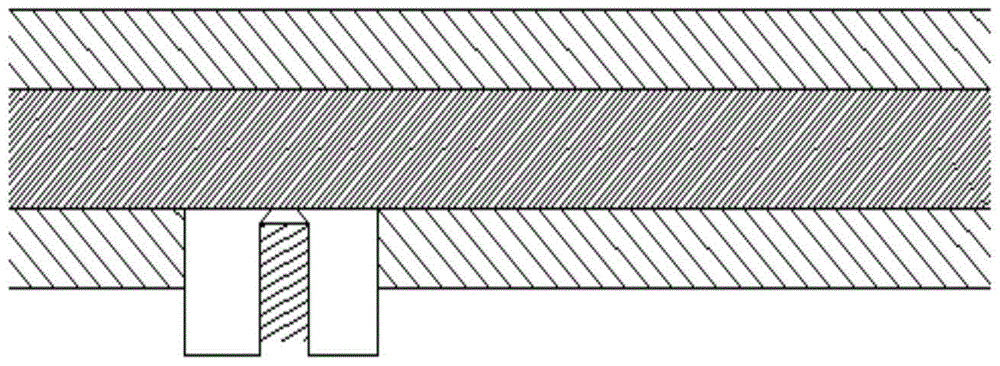

[0045] Depend on figure 1 As shown, the device for realizing the indoor experiment of carbon dioxide miscible flooding includes the following components, that is, the thin tube drain valve 9, the core experiment control valve 10, the saturated oil narrow tube valve 11, the liquid drain valve 12, the pressure holding valve 13, the thin tube Pipe valve 14, external equipment connector 15, reagent adding constant pressure constant speed pump 16, piston container 17, adding reagent storage tank 18, adding reagent flow totalizer 19, carbon dioxide flow totalizer 20, high temperature and high pressure visualization device 21, Conventional visualization capillary 22, capillary miscible monitor 23, rock core miscible monitor 26, saturated oil capillary miscible monitor 29, miscible monitor 30, natural rock core 24, core pressure monitor 25, capillary pressure monitor 28, Pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com