An image capture device for quality inspection and analysis of machine tool guide rail surface

An image capturing and rail surface technology, which is applied to measuring devices, optical devices, instruments, etc., can solve problems such as large detection errors, and achieve the effects of time-consuming and labor-intensive, simple structure and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

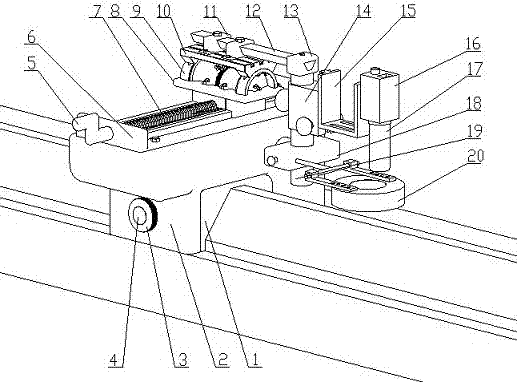

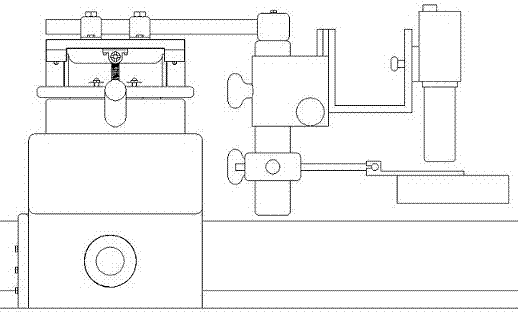

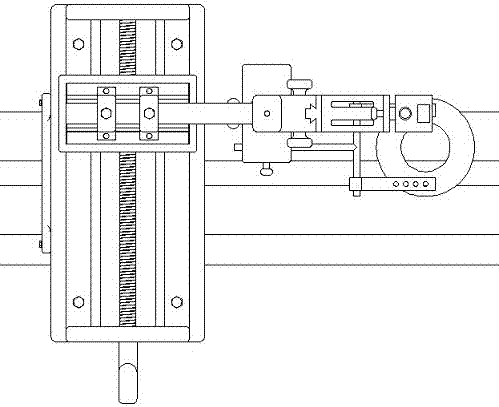

[0025] Embodiment 1, the present invention includes a moving box, a sliding assembly, a rotating assembly, and a shooting assembly; Fitted with the guide rail to be detected; the sliding assembly includes a handle 5, a sliding body 6, a lead screw 7, and a mobile platform 8, the sliding body 6 is fixed above the outer box 2, and the upper surface of the sliding body is provided with Sliding track, the mobile platform 8 is installed above the sliding track, and the lower end is provided with a threaded hole, and one end of the screw 7 is provided with a handle 5, which passes through the threaded hole at the lower end of the mobile platform 8 and is installed on the sliding body 6; The assembly includes a rotating base 9, a worm 21, a rotating platform 10, and a fixed block 11. The rotating base 9 is fixed above the mobile platform 8. The overall shape is semicircular and the diameter at both ends is large and the diameter in the middle is small. There are circumferential guides...

Embodiment 2

[0026] Embodiment 2, the working process of the present invention: connect the light 27 and the eyepiece 17 to an external power supply and a computer, adjust the eyepiece moving device 14, move the square block 18 to an appropriate position and tighten it, and move the light device 20 along the moving square block 18 The inner hole is moved so that the centerline of the eyepiece 17 and the centerline of the light 27 are roughly in a straight line, the relative position of the eyepiece 17 and the light 27 is adjusted by the fine-tuning knob 28 to make the picture quality optimal, and the mobile platform 8 is moved by shaking the handle 5 To the appropriate position, the rotating worm 21 realizes the rotation of the rotating platform 10, so that the eyepiece 17 reaches the position perpendicular to the slope of the guide rail surface, adjusts the fine-tuning knob 28 again to make the shooting effect reach the best, and then shoots, and rotates the handwheel 3 to realize the whole...

Embodiment 3

[0027] Embodiment 3, the inner rail cover 1 in the mobile box described in the present invention moves based on the rail surface to be tested itself. refer to Figure 1 to Figure 6 , all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com