Spherical densely-covered type probe ultrasonic thickness measurement device used for detection in pressure pipeline

A pressure pipeline, densely distributed technology, applied in the field of spherical densely distributed probe ultrasonic thickness measuring devices, can solve problems such as difficult elbow corrosion detection, difficult sound beam vertical or almost perpendicular to the inner wall, unable to obtain sufficient intensity ultrasonic signals, etc., to achieve Effects of compact structure, overcoming sound energy loss, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

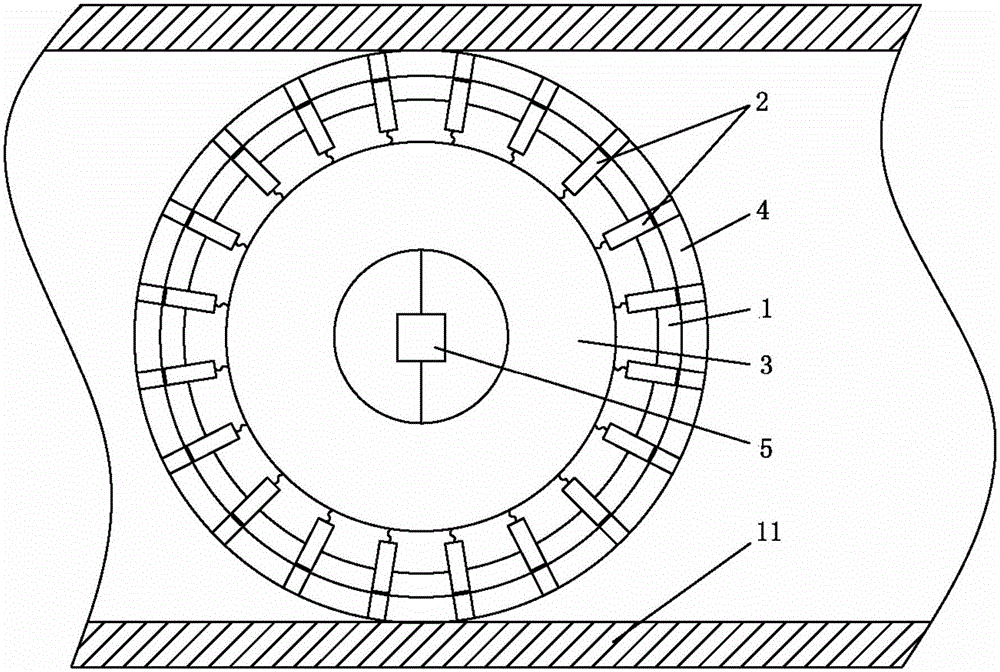

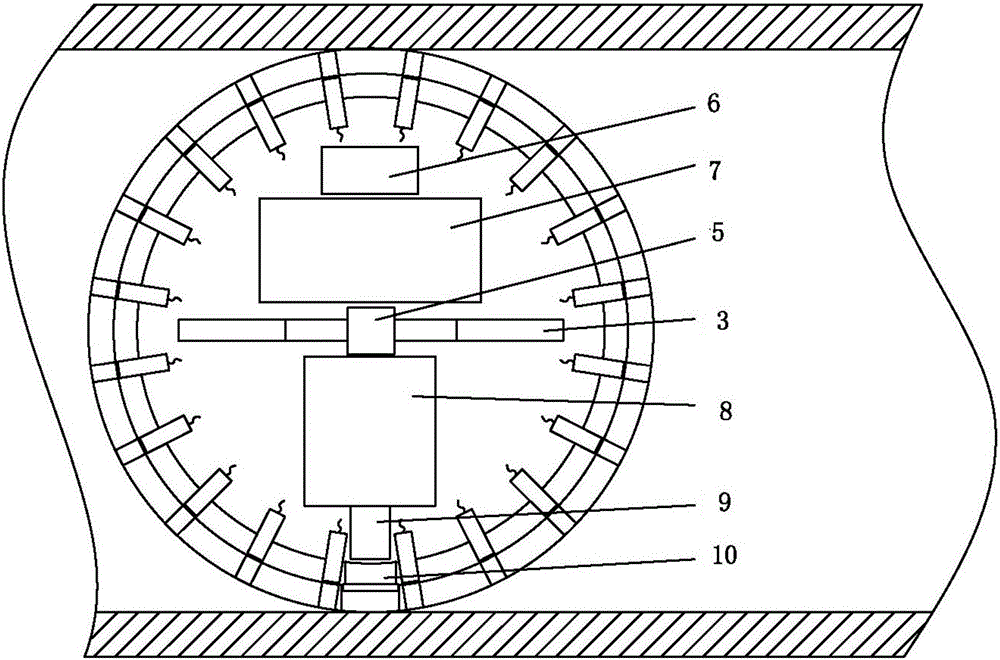

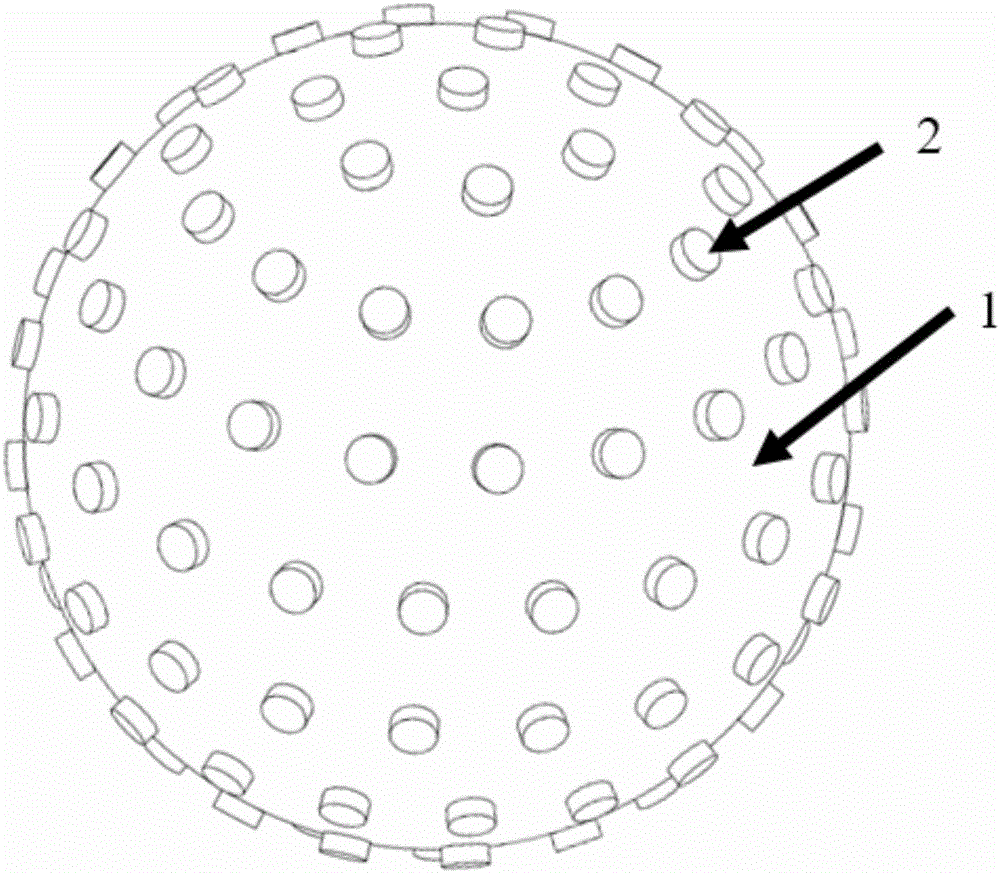

[0031] Such as Figure 1-1 to Figure 5 As shown, the ultrasonic thickness measuring device with spherical densely distributed probes for detection in pressure pipelines provided by the present invention includes a spherical housing 1, several ultrasonic probes 2, a multi-channel ultrasonic card 3, a spherical outer cover 4, an accelerometer 5 and a magnetometer 6 , high-efficiency battery 7, embedded PC platform 8, U disk storage 9, screw plug 10, etc., so as to realize the wall thickness measurement of the pressure pipeline 11.

[0032] The plurality of ultrasonic probes are evenly distributed on the spherical shell, and are connected to the signal processing device inside the spherical shell through wires; through holes. The plurality of ultrasonic probes are arranged outward along the radial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com