Large rotating supporting rolling way abrasion automatic detecting system and arge rotating supporting rolling way abrasion automatic detecting method

A technology of slewing bearing and detection system, which is applied in the detection field to achieve the effect of improving the safety of use and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

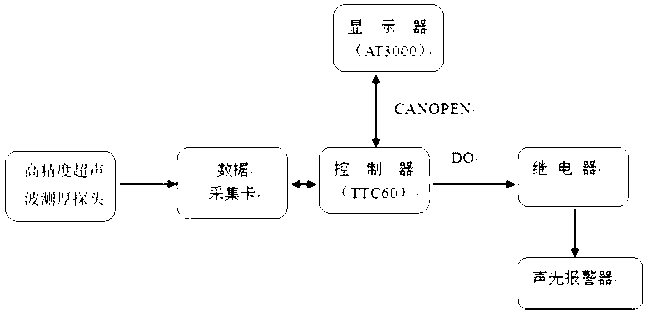

[0031] Such as figure 1 As shown, a wear detection system for QND1250 slewing bearings is composed of hardware and software. The hardware is composed of 35 / 35DL high-precision ultrasonic thickness measuring probe, data acquisition card, TTC60 controller, AT3000 display, and relay. , sound and light alarm and cable power supply; the software part is composed of signal communication module, drive control module, data acquisition and processing module, and alarm module.

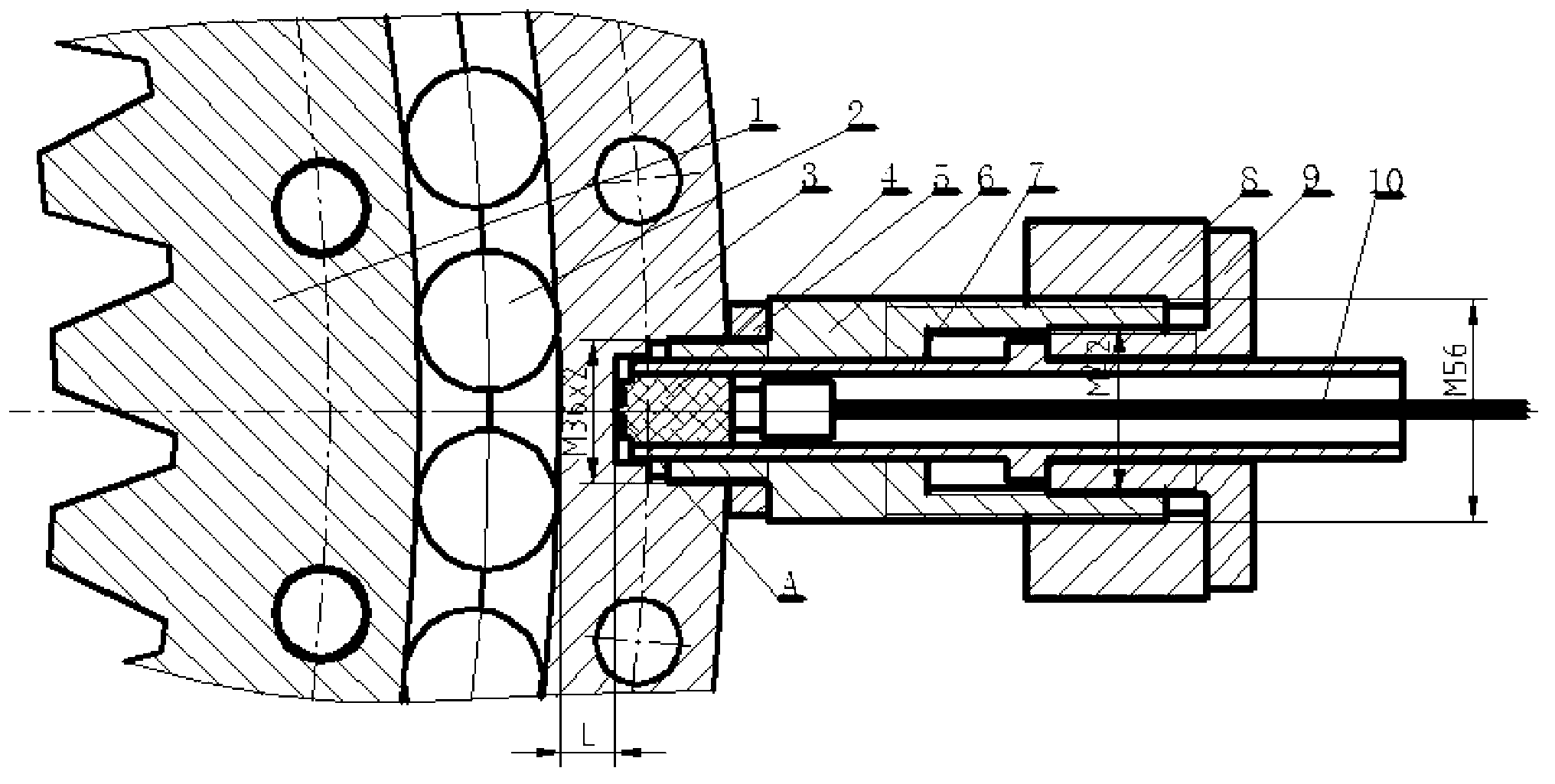

[0032] Such as figure 2 As shown, a radial blind hole of φ30 is drilled on the fixed outer ring 3 of the QND1250 slewing bearing until the thickness to be measured is 18mm, and the inner thread M36 is tapped, and the signal line of the high-precision ultrasonic thickness measuring probe 4 is connected to the Insert the push tube 7 from left to right. Since the left side of the push tube 7 is a wedge-shaped inner opening, the high-precision ultrasonic thickness measuring probe 4 can be fixed, and then the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com