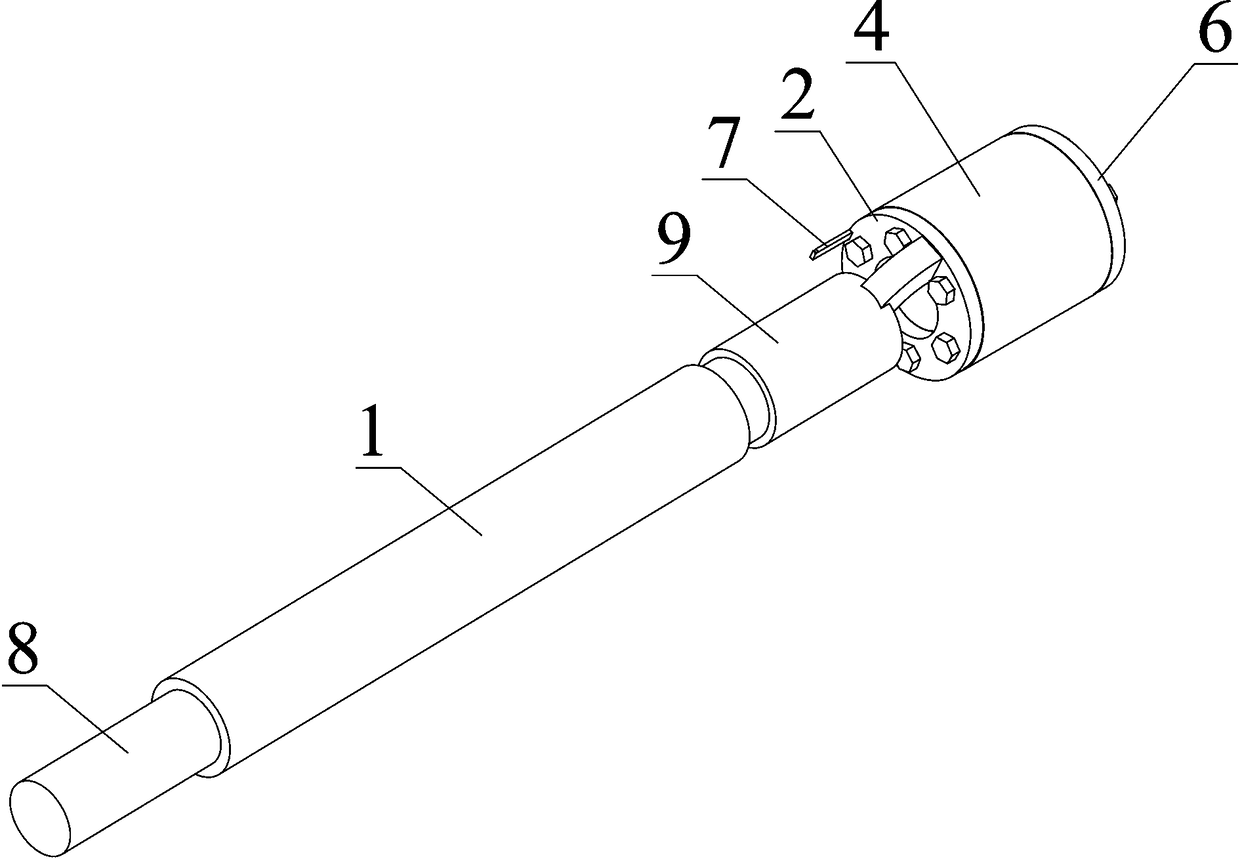

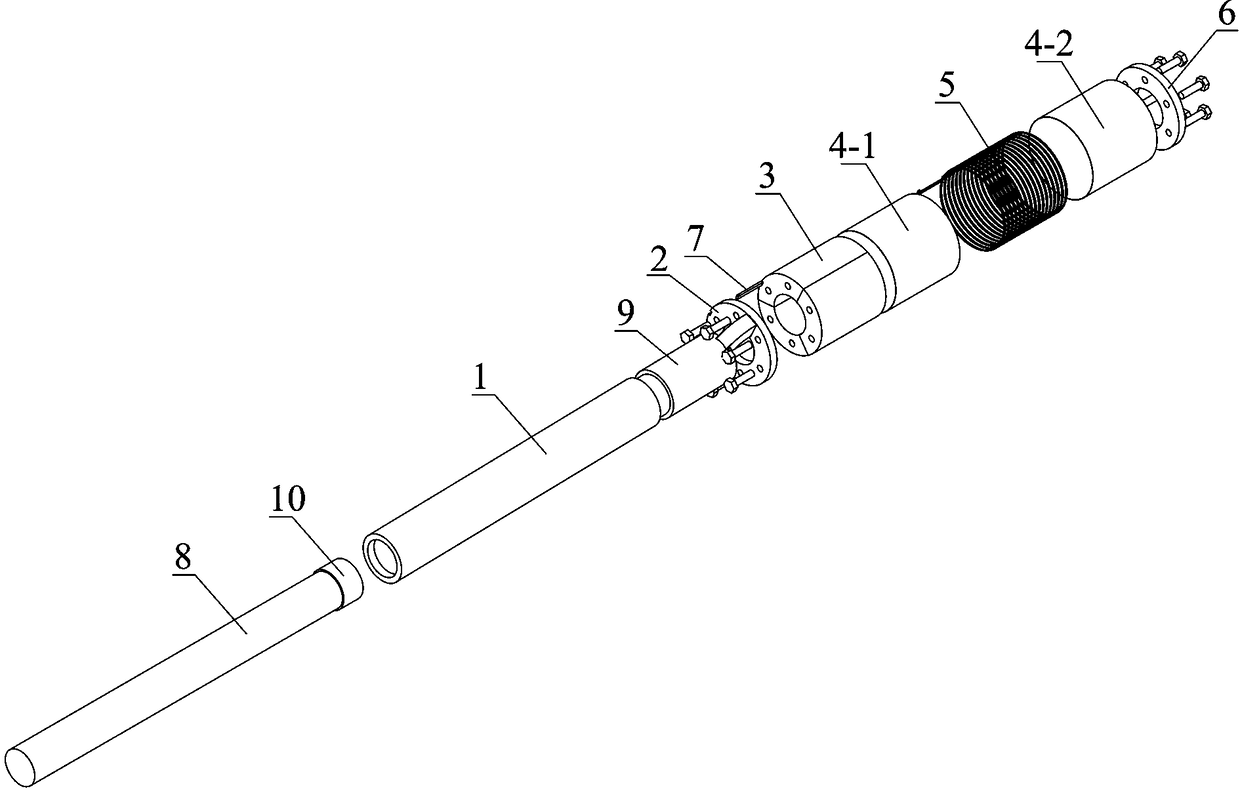

Internal inspection electromagnetic ultrasonic thickness measurement energy converter structure of circular pipeline

An electromagnetic ultrasonic and transducer technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of long acoustic wave propagation distance, electromagnetic ultrasonic thickness measurement transducer design and research, etc., to prolong the service life. , Realize the effect of engineering detection application and protection coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

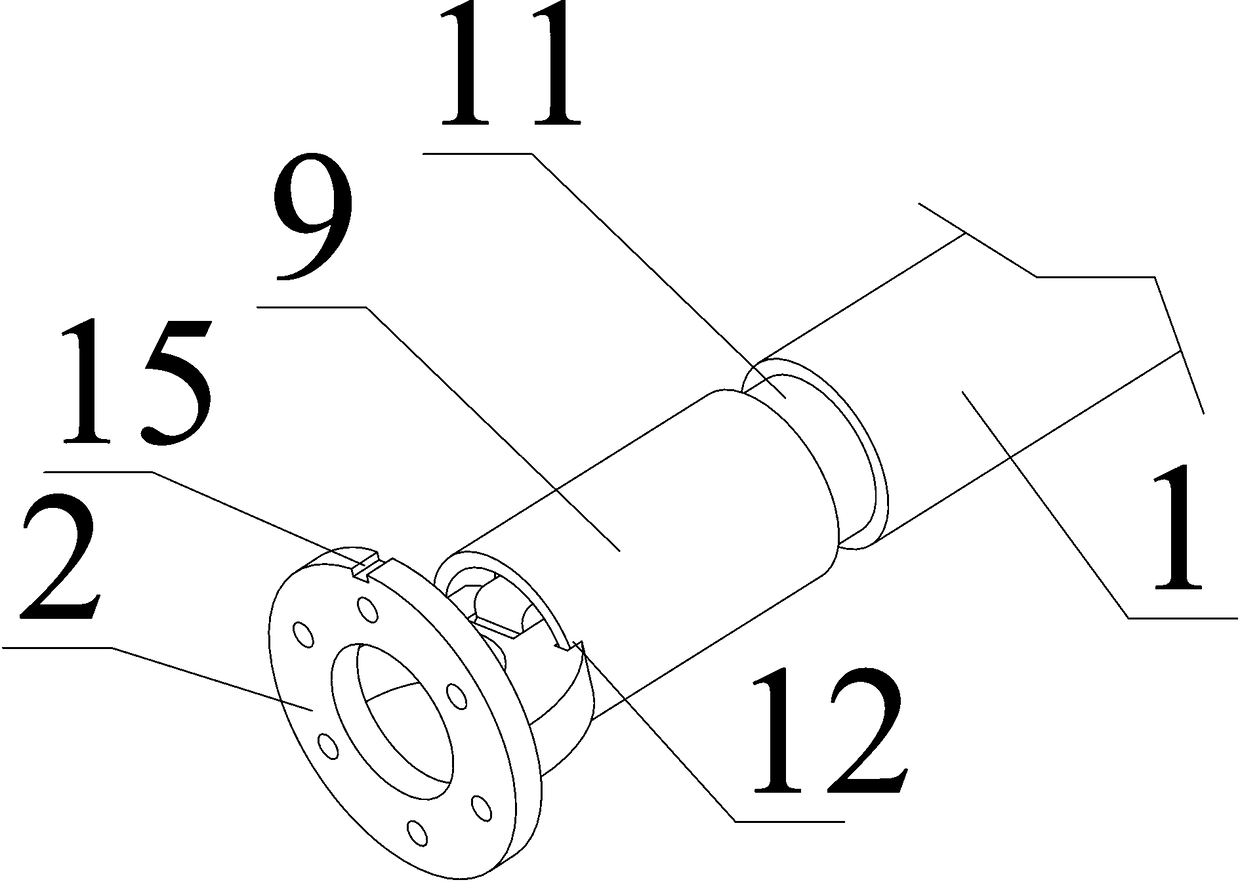

[0046] The structure of the transducer adopts a transceiver integrated thickness measuring coil and adopts a single-strand circumferential winding wiring design. A wire with a thickness of 0.05mm and a width of 1mm (taking a reference line with a height of 65mm as the axis) is wound into a hollow cylinder structure, and the wire extends into the The end is located on the side of the cylinder, the length is equal to the height of the cylinder, the diameter of the coil is 50mm, and the distance between adjacent wires is 2mm.

[0047] The transducer structure using this coil penetrates deep into the inner side of the pipe and can detect the thickness of the pipe.

Embodiment 2

[0049] The structure of the transducer adopts the separation of sending and receiving. The thickness measuring coil adopts the double-strand circumferential winding wiring design. Two strands of wires with a thickness of 0.05mm and a width of 1mm are nested in parallel (taking a reference line with a height of 65mm as the axis) and are wound into a hollow cylinder. Body structure, the two strands of wires are parallel to each other and 1.5mm apart, both located on the side of the cylinder, the length is equal to the height of the cylinder, the distance between adjacent wires of a single strand is 2mm, and the distance between adjacent wires between double strands is 0.5mm (adjacent wires pitch 0.5mm), coil diameter 50mm.

[0050] The transducer structure using this coil penetrates deep into the inner side of the pipe and can detect the thickness of the pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com