Ultrasonic thickness measurement system for aqueous film/water line at surface of staying cable

A surface water film and ultrasonic technology, which is applied in the field of bridge construction, can solve the problems of not being able to ensure the accuracy of waterline thickness and width direction at the same time, not being able to track waterline movement well, and not being able to obtain water film/waterline, etc. Simple, high-precision, and real-time monitoring of system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

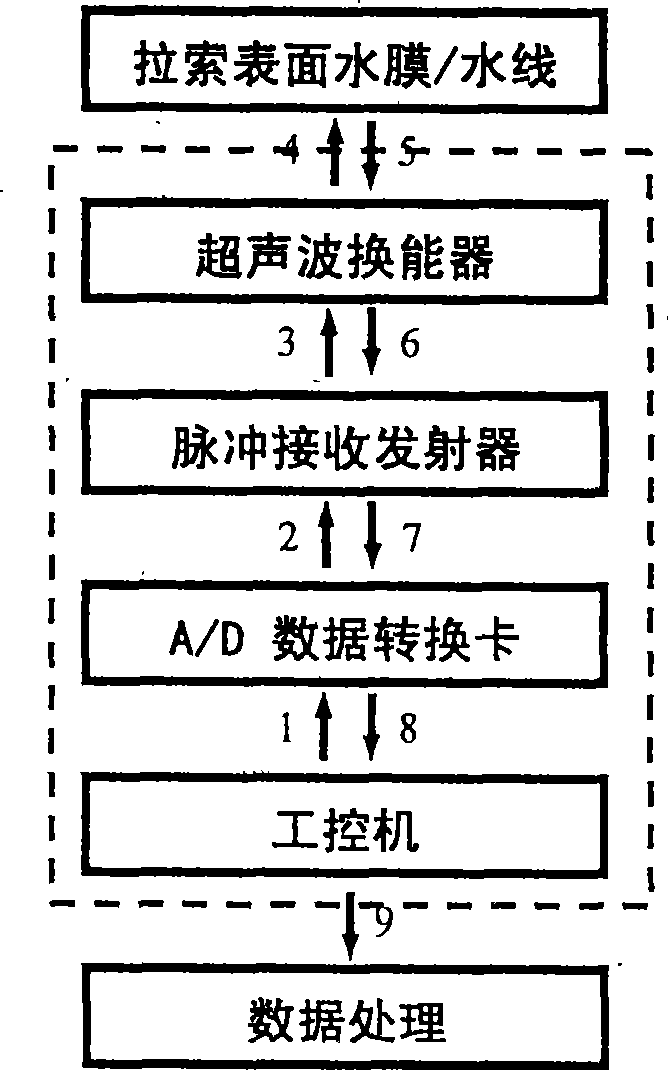

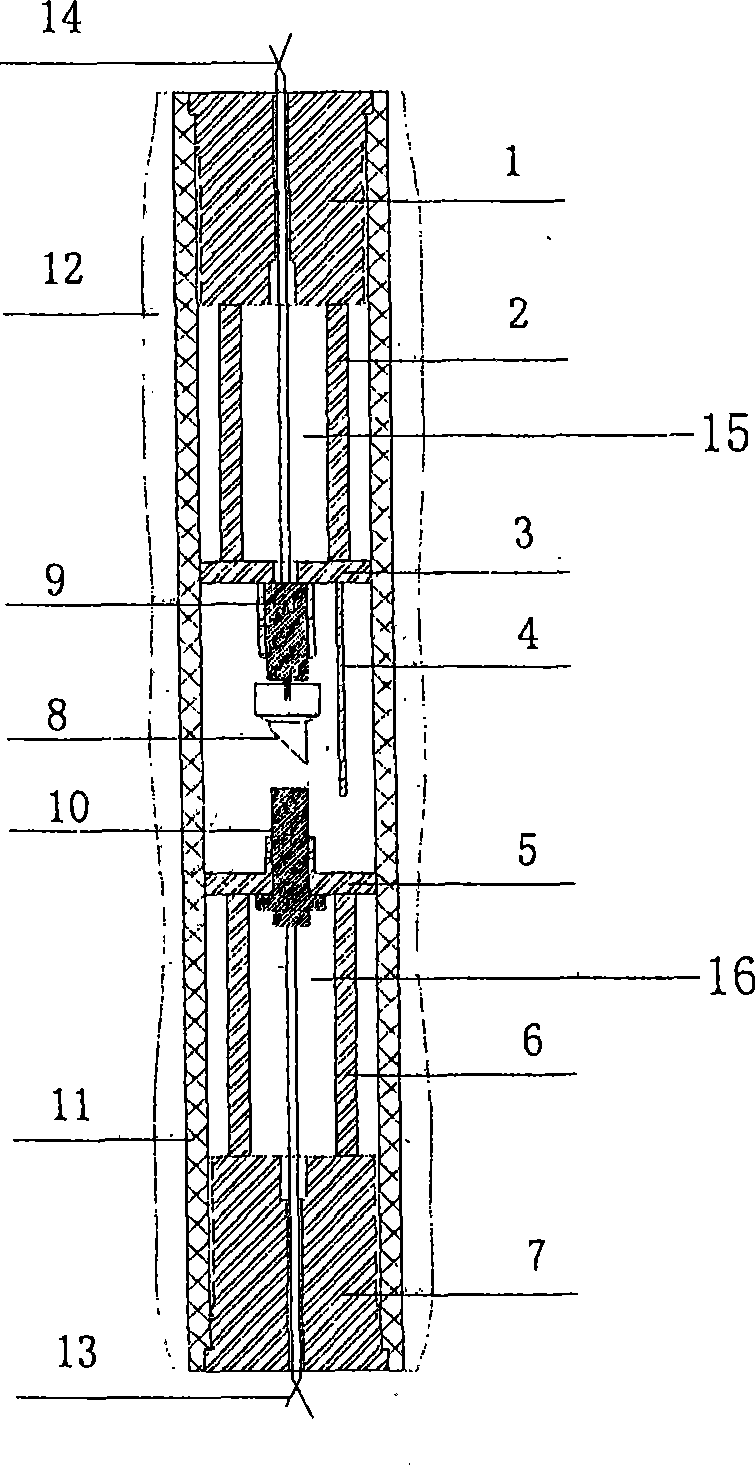

[0025] Embodiment 1, combining figure 1 , The ultrasonic thickness measuring system of the water film / water line on the surface of the stay cable of the present invention is composed of a software system and a hardware system. The software system includes a data acquisition program and a data processing program. The acquisition program is written in Bland C++ language, and the thickness of the water film / water line is collected in real time and continuously during the wind and rain excitation process, and the data volume is huge; the data processing program is written in Matlab. Mass processing of water film / water line thickness data. The hardware system is divided into the external device of the stay cable model and the internal device of the model. The external device of the cable stay model includes: industrial computer, A / D high-speed data conversion card, pulse receiving transmitter and DC stabilized power supply; the internal device of the cable stay model is composed o...

Embodiment 2

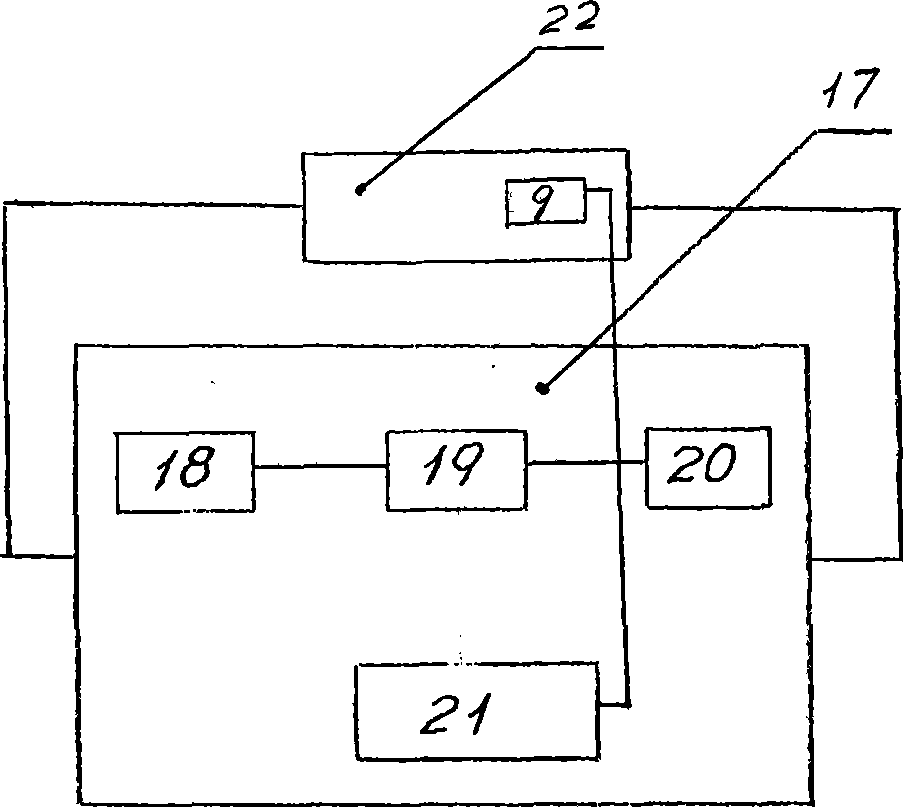

[0026] Example 2, combined with figure 2 , the industrial computer of the stay cable model external device of the present invention is mainly to run the acquisition program, save the massive data converted by the A / D high-speed data conversion card, and require the hard disk to be large-capacity (more than 500G), high-speed (10000 rpm above). The function of the A / D high-speed data conversion card is to convert the voltage signal into a digital signal, and the acquisition speed of the conversion card is selected according to the crystal frequency of the ultrasonic transducer. The function of the pulse receiving transmitter is to send a high-voltage pulse to the ultrasonic transducer, so that the chip on the transducer vibrates at a high frequency (for example, 10MHz) to generate a high-frequency ultrasonic pulse signal. At the same time, the ultrasonic acoustic transducer can receive the ultrasonic echo signal reflected from the upper and lower surfaces of the measured water...

Embodiment 3

[0027] Example 3, combined with figure 1 , the working process of the ultrasonic thickness measuring system for the water film / water line on the surface of the cable stay is as follows: the industrial computer starts the acquisition program, sends an instruction to the pulse transmitter receiver through the A / D data conversion card, and the pulse transmitter receiver sends the ultrasonic wave to the receiver. The transducer emits a high voltage, and under the action of the high voltage, the transducer vibrates to generate ultrasonic pulses. Then the ultrasonic pulse is reflected twice on the upper and lower surfaces of the water line / water film, and the echo signal is converted into a low-voltage signal by the ultrasonic transducer and the pulse transmitter receiver and transmitted to the A / D high-speed data conversion card, and finally through the A / D Convert, store the signal in digital form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com