Device for measuring thickness of any point of free-form surface and measuring method thereof

An arbitrary point and curved surface technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low measurement accuracy, large structural size of parts, and many points to be measured, so as to ensure measurement accuracy and improve processing Accuracy, the effect of ensuring the coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

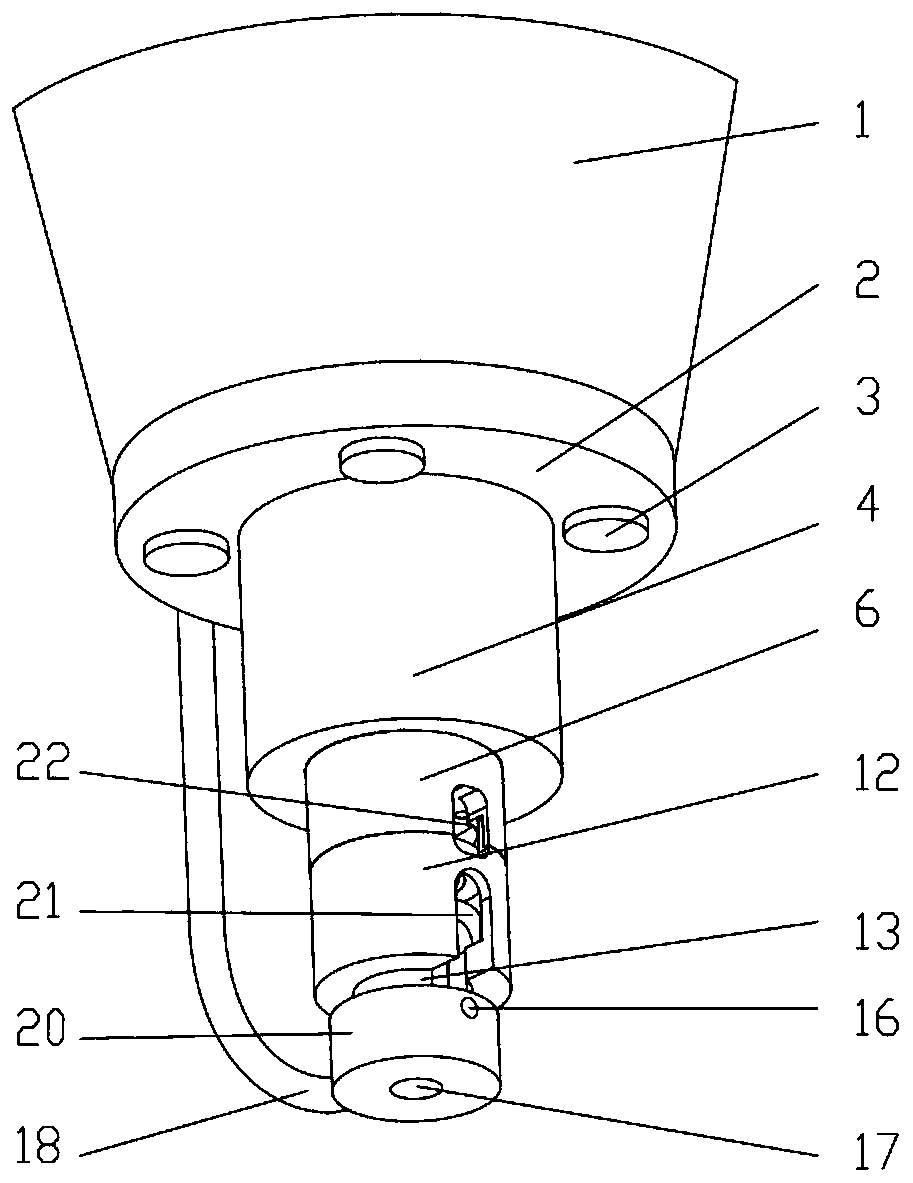

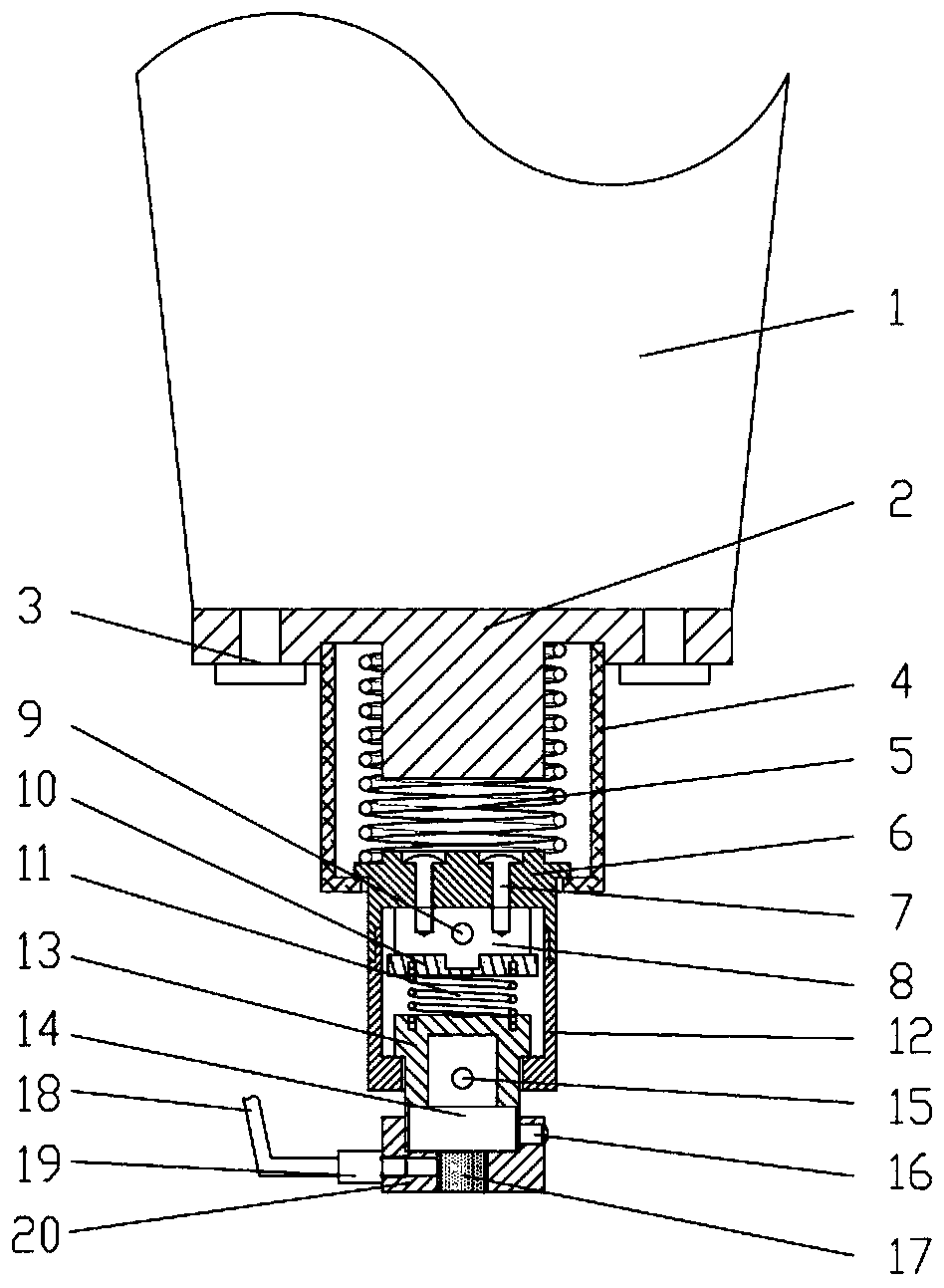

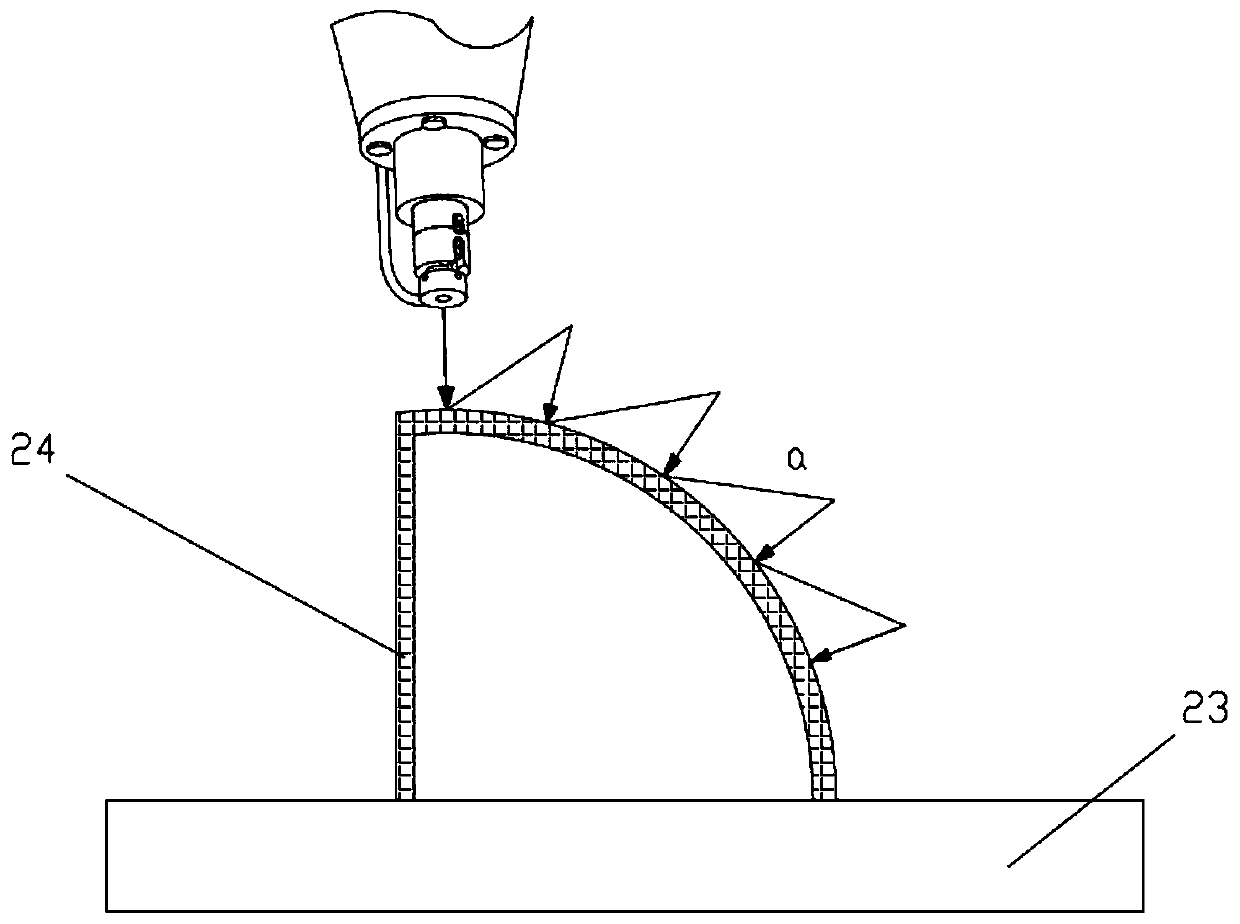

[0032] A device for measuring the thickness of any point on a free-form surface, coaxially installed at the end of an industrial detection robot, used to detect a certain aluminum thin-walled curved surface workpiece, such as figure 1 , figure 2 As shown, the device includes an ultrasonic thickness measurement main structure, a buffer connection structure and a coupling agent supply structure.

[0033] The main structure of ultrasonic thickness measurement includes ultrasonic thickness measurement probe 14 , probe delay block 17 , ultrasonic probe fixing sleeve 13 , upper casing 6 , lower casing 12 , angle adaptive spring 11 , pressure transmission plate 10 , and miniature pressure sensor 8 . The probe delay block 17 is installed at the end of the ultrasonic thickness measuring probe 14, and is coaxially fixed in the ultrasonic probe fixing sleeve 13. The same side of the ultrasonic probe fixing sleeve 13 and the pressure transmission plate 10 has a circular groove with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com