Supply chain based multi-period inventory optimization and management method

A technology for inventory optimization and management methods, applied in data processing applications, forecasting, logistics, etc., can solve problems such as lack of quantitative and in-depth research, and achieve low inventory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

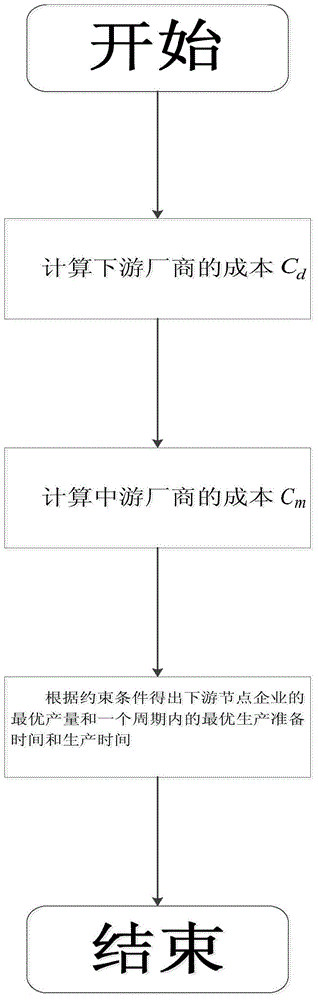

[0031] The invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] 1. Cost C of downstream manufacturers d constitute:

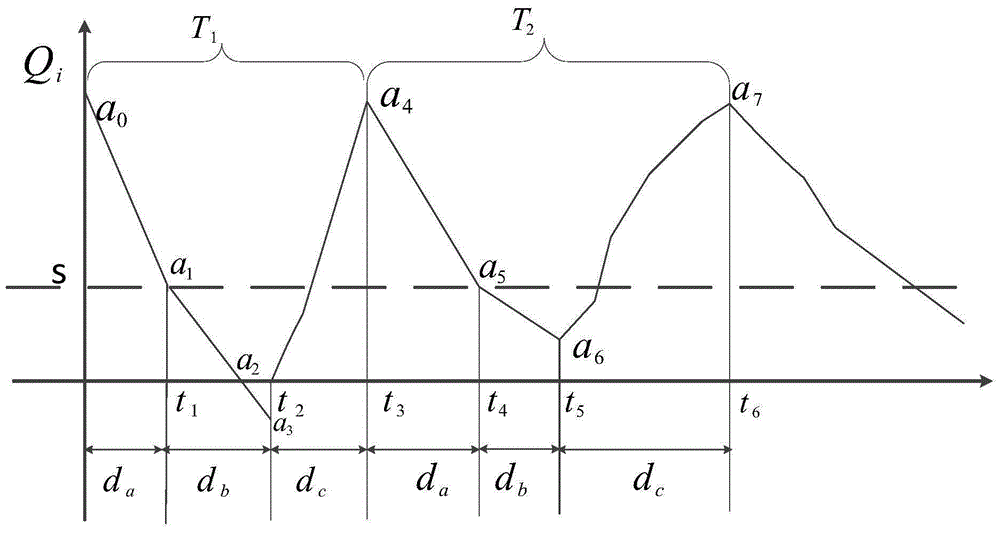

[0033] figure 1 It is a schematic diagram of the inventory of product P of the downstream manufacturer i, and the order cycle of the downstream manufacturer i in the supply chain is used as the benchmark for analysis, using (s, Q i)’s production strategy controls the production of downstream enterprise i, and prepares for production when the inventory of finished products drops to s, and the production volume is Q i ; There is no shortage of raw materials during production, and the storage cost of raw materials is not included in the cost of this system. throughout T n During the time period, the user's demand for the product P of the downstream manufacturer i in each time period is

[0034] A. Out-of-stock loss E(η of downstream node enterprise i i ):

[0035] figure 1 In a production cycle T of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com