Cable cutting device and working method thereof

A cutting device and cable technology, applied in the direction of dismantling/armouring cable equipment, circuits, electrical components, etc., can solve problems such as damage, increased labor time and workload, and inconvenient operation, so as to achieve high reliability and save working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

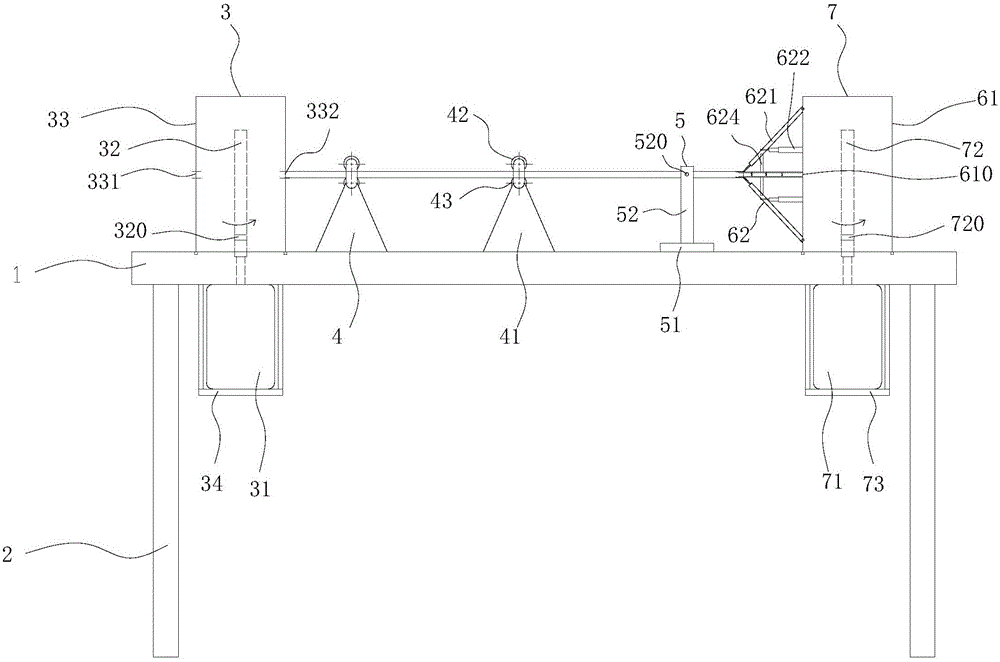

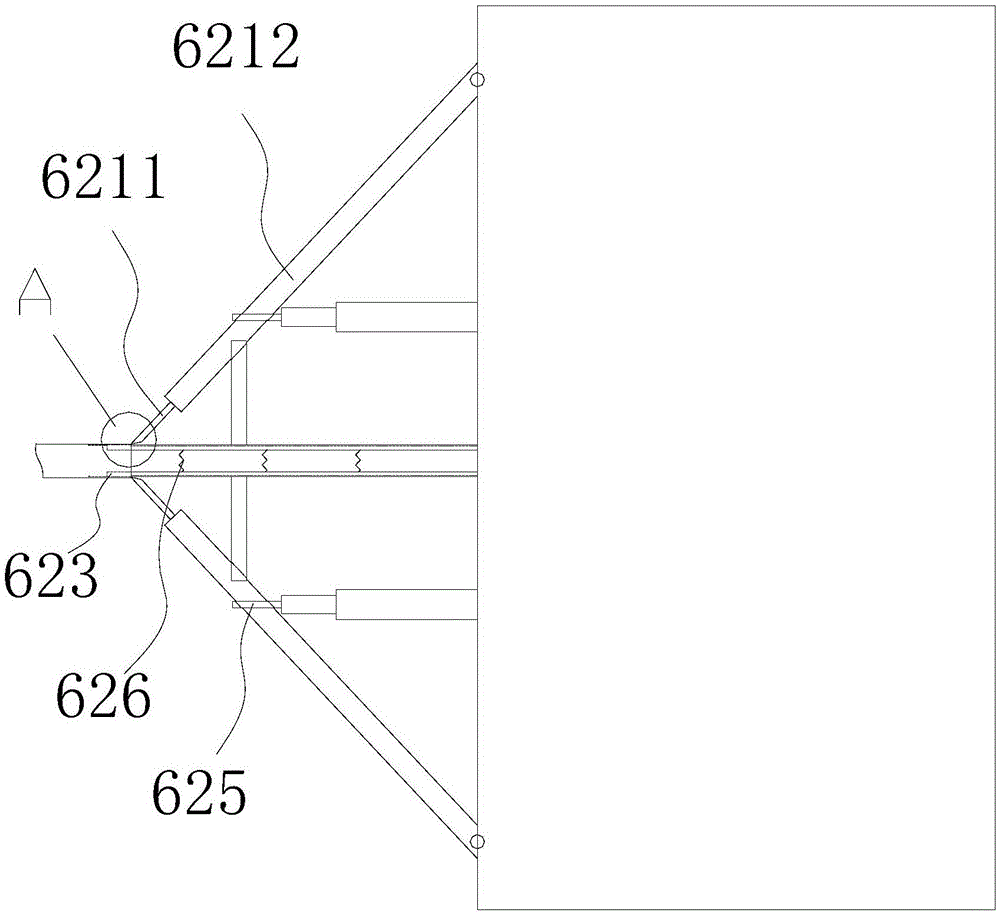

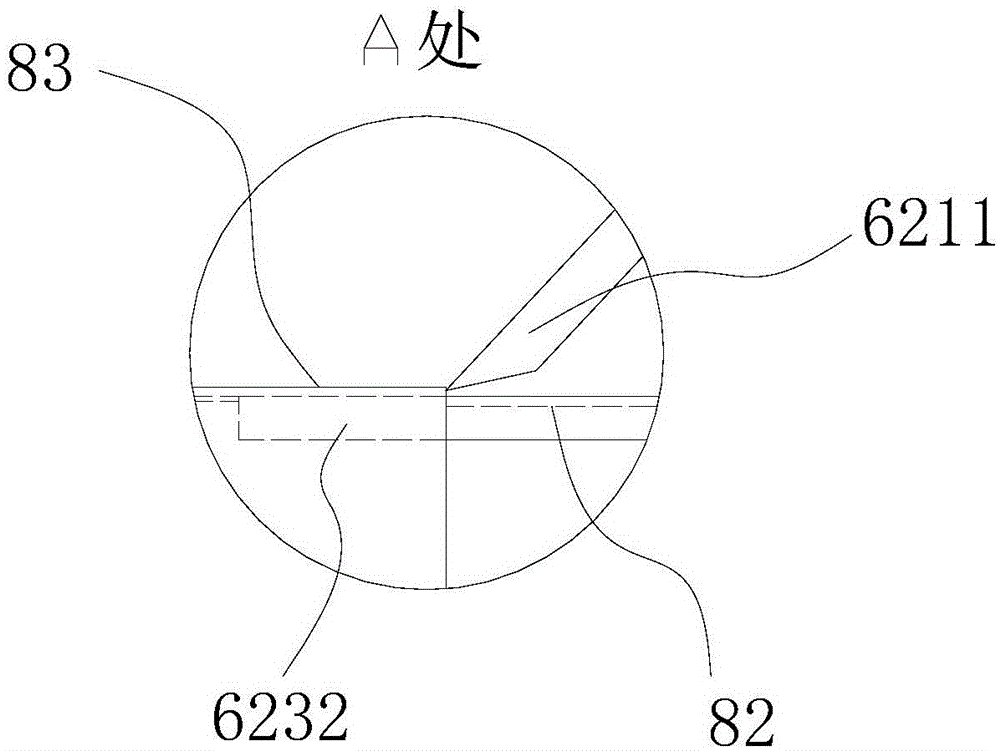

[0050] The invention as Figure 1-9 As shown, it includes a workbench 1 and a foot 2 arranged under the workbench 1; the workbench 1 is sequentially provided with a cable collection mechanism 3, a guide mechanism 4, a separation mechanism 5, a cutting mechanism 6 and a wire core collection mechanism 7;

[0051] Described cable collecting mechanism 3 comprises motor one 31 and rotating shaft one 32, and described motor one 31 is arranged on the bottom surface of described workbench 1 by support frame one 34, and described motor one 31 drives rotating shaft one 32 to rotate, and described rotating shaft One is perpendicular to the top surface of the workbench, the rotating shaft one 32 is provided with a perforation one 320, the perforation one is convenient for the connection of the cable head, and then makes the rotation and winding of the cable reliable, which is convenient for collecting and ordering the messy cables; Then, perform subsequent operations;

[0052] Described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com