Vegetation slope protection method

A technology of vegetation and plant fiber materials, applied in the field of environmental protection and greening, to achieve the effects of easy operation, solving the problem of slope protection, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

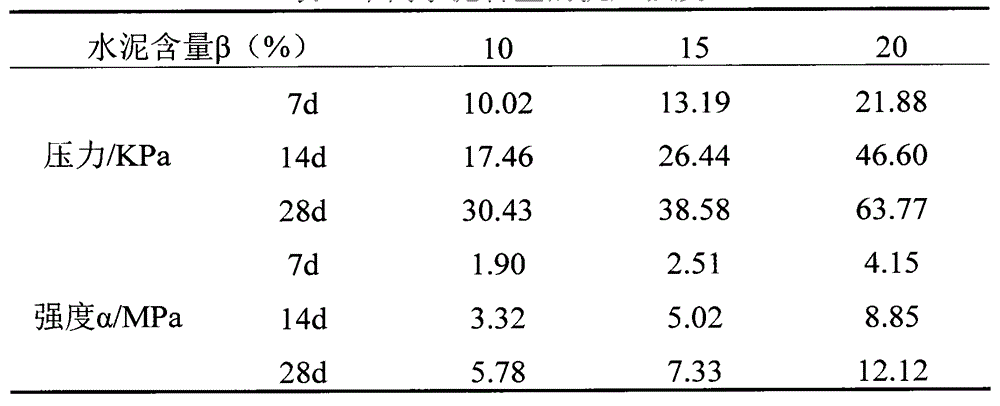

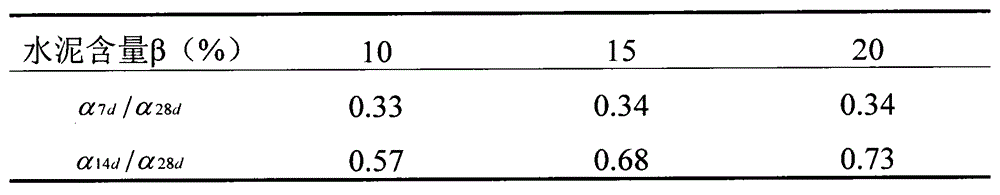

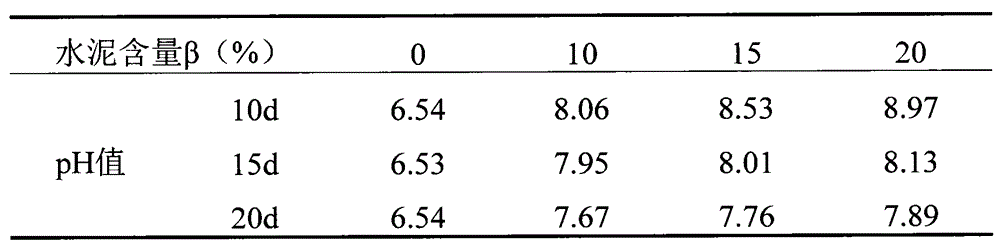

Embodiment 1

[0032] The present embodiment provides a vegetation slope protection method, comprising the steps of:

[0033] Step 1. Prepare slope protection matrix mixture: mix 250g of plant fiber material, 750g of organic matter, cement, 4000g of soil, 50g of fertilizer, 1g of water retaining agent, and 2240g of water, and add 10% of the cement that accounts for the total weight of all the above components, and stir evenly Obtain slope protection matrix mixture;

[0034] Step 2. Preparation of slope protection matrix bricks: mold the slope protection matrix mixture, place it on a shaking table to compact it into a size of 50cm×30cm×3cm, and place it in a standard curing room for curing after molding. After 3 days of curing, it is demoulded and soaked in a sealed environment Slope protection matrix bricks can be obtained at the age;

[0035] Step 3. Slope protection operation: Place the slope protection matrix bricks on the slope surface that needs to be maintained, and then carry out the...

Embodiment 2

[0037] The present embodiment provides a vegetation slope protection method, comprising the steps of:

[0038] Step 1. Prepare slope protection matrix mixture: mix 250g of plant fiber material, 750g of organic matter, cement, 4000g of soil, 50g of fertilizer, 1g of water-retaining agent, and 2240g of water, and add 15% cement accounting for the total weight of all the above components, and stir evenly Obtain slope protection substrate mixture;

[0039]Step 2. Preparation of slope protection matrix bricks: mold the slope protection matrix mixture, place it on a shaking table to compact it into a size of 50cm×30cm×3cm, and place it in a standard curing room for curing after molding. After 3 days of curing, it is demoulded and soaked in a sealed environment Slope protection matrix bricks can be obtained at the age;

[0040] Step 3. Slope protection operation: Place the slope protection matrix bricks on the slope surface that needs to be maintained, and then carry out the sowing,...

Embodiment 3

[0042] The present embodiment provides a vegetation slope protection method, comprising the steps of:

[0043] Step 1. Prepare the slope protection matrix mixture: mix 250g of plant fiber material, 750g of organic matter, cement, 4000g of soil, 50g of fertilizer, 1g of water retaining agent, and 2240g of water, and add 20% of the cement that accounts for the sum of the weight of all the above components, and stir evenly Obtain slope protection substrate mixture;

[0044] Step 2. Preparation of slope protection matrix bricks: mold the slope protection matrix mixture, place it on a shaking table to compact it into a size of 50cm×30cm×3cm, and place it in a standard curing room for curing after molding. After 3 days of curing, it is demoulded and soaked in a sealed environment Slope protection matrix bricks can be obtained at the age;

[0045] Step 3. Slope protection operation: Place the slope protection matrix bricks on the slope surface that needs to be maintained, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com