Swell-shrink characteristic rock-soil cut slope protection method and structure

A technology for slopes and dirt roads, which is used in infrastructure engineering, excavation, sheet pile walls, etc., to achieve the effect of increasing slope stability, good environmental protection landscape, and strong integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for protecting the slope of an expansive rock-soil cutting, the steps of which are:

[0033] a. Excavation side slope: According to the design slope ratio (1:1.0 or 1:1.25 or 1:1.50 or 1:1.75), excavate the cutting side slope in stages from top to bottom to level the slope surface.

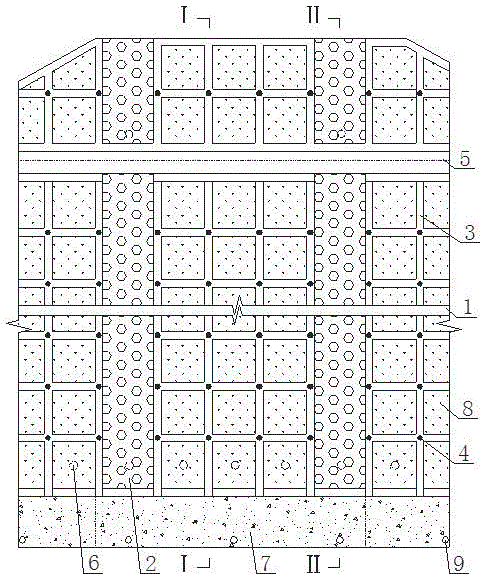

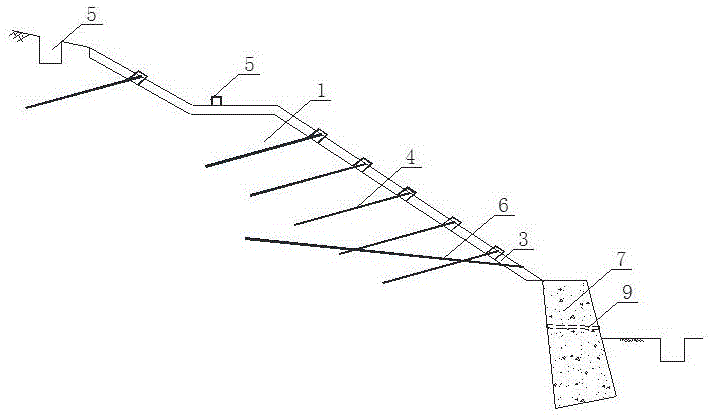

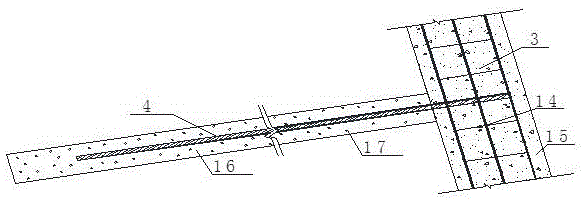

[0034] b. Construction lofting: On the surface of slope body 1, according to the overall structure elevation diagram of a structure to protect the expansion and shrinkage rock-soil cutting slope, support seepage ditches, anchor rods, reinforced concrete frames, intercepting ditches, and toe walls, etc. Stakeout of the structural unit, at intervals of a certain distance (6m or 8m or 10m) along the longitudinal direction of the cutting slope, a supporting seepage ditch 2 stakeout line is arranged from the top to the bottom of the slope; the slope body 1 between the two supporting seepage ditch On the surface, arrange criss-crossing square mesh (grid spacing is 2m or 3m) reinforced co...

Embodiment 2

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] Such as Figure 1 to Figure 5 As shown, a structure for protecting the expansive rock-soil cutting slope, which consists of a cutting slope body 1, a supporting seepage ditch 2, a reinforced concrete frame beam 3, an anchor rod 4, a water intercepting ditch 5, and an inclined drainage ditch 6. The toe wall 7 is composed of soil spraying and grass planting 8, which is characterized in that: longitudinally along the cutting slope, every 6m or 8m or 10m. A supporting seepage ditch 2 is arranged on the surface of the slope body 1 from top to bottom, and the surface of the slope body 1 between every two supporting seepage ditch 2 is provided with criss-crossing reinforced concrete frame beams 3, and each intersection of the frame beams 3 is provided with a The roots are implanted into the anchor rod 4 of the slope body, and each frame beam 3 compartments a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com