Zipper puller with independent locking mechanism

A locking mechanism and slider technology, applied in the field of zippers, can solve problems such as unsmooth pulling feeling, complex structure, and sliding, and achieve the effects of stable self-locking and unlocking functions, simplified assembly, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

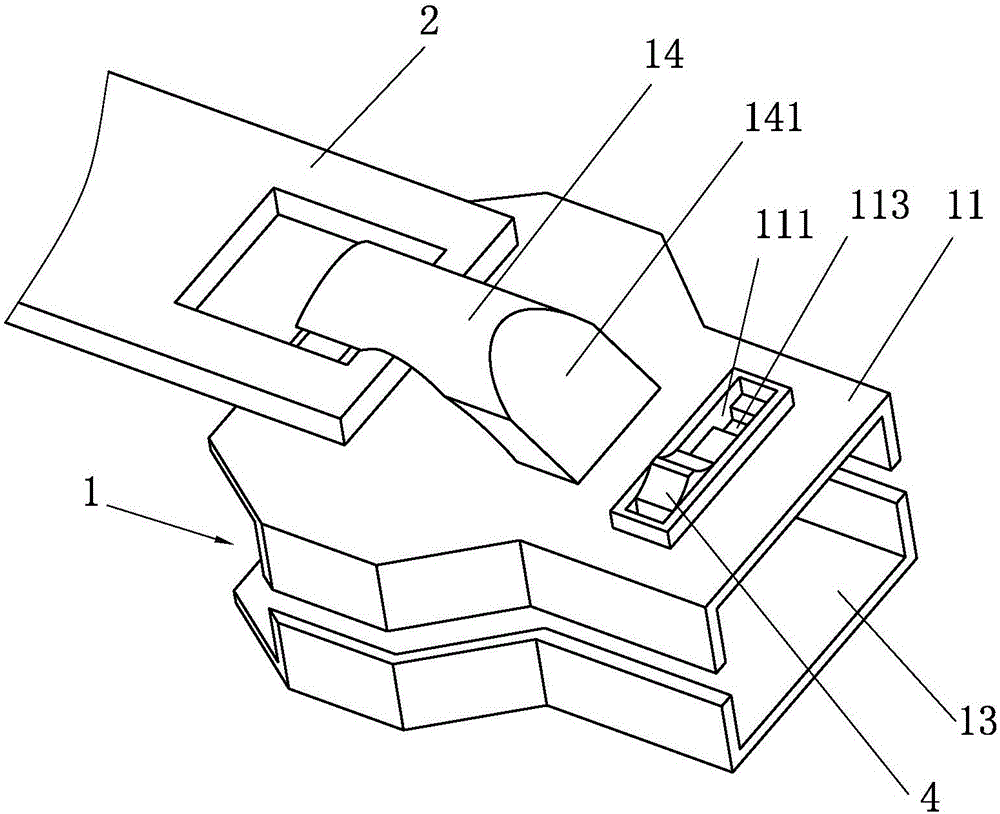

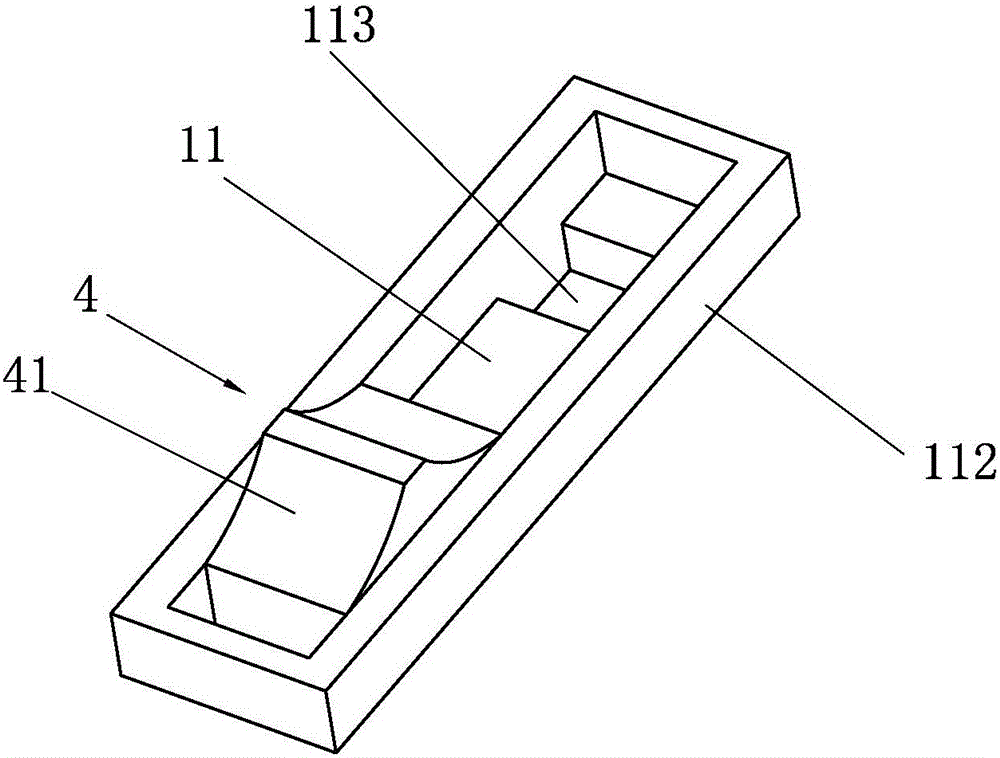

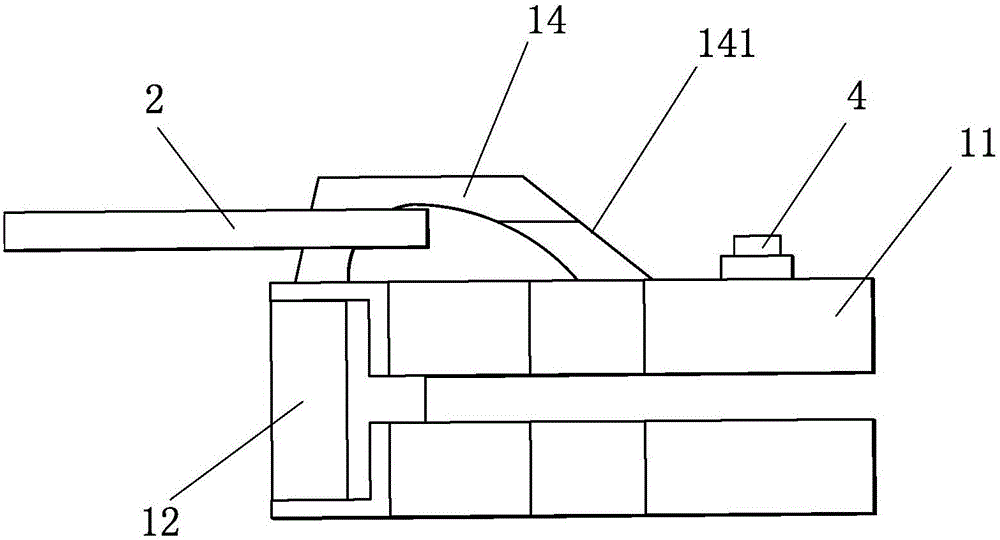

[0023] like Figure 1 to Figure 3 As shown, a slider with an independent locking mechanism includes a slider body 1, a pull piece 2 and a slider 4. The slider body 1 has an upper wing 11 and a lower wing 13 connected by a guide post 12, Upper and lower wing plates 11, 12 are supported and connected by guide posts 12 at the large ends, and the upper wing plate 11 is provided with an elephant trunk 14 for installing the pull piece 2, and the small end of the upper wing plate 11 is provided with a chute 111 for sliding The groove 111 is equipped with a sliding block 4 through a limiting groove provided on its side wall, and the sliding block 4 can slide in the sliding groove 111 . In order to make the slider 4 have enough layout positions, and the fingers can operate the slider 4 more conveniently without being hindered, the length of the eleph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com