Automatic paster toilet seat cover

A toilet lid and toilet technology, applied in the field of sanitary equipment, can solve the problems of unsanitary, large area of toilet seat paper, inconvenient folding, etc., and achieve the effects of reducing production cost, reducing area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

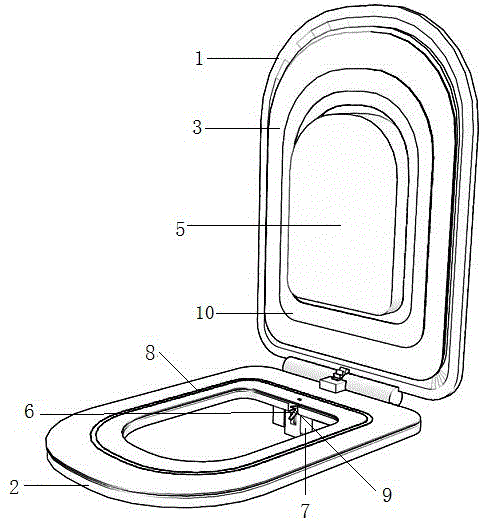

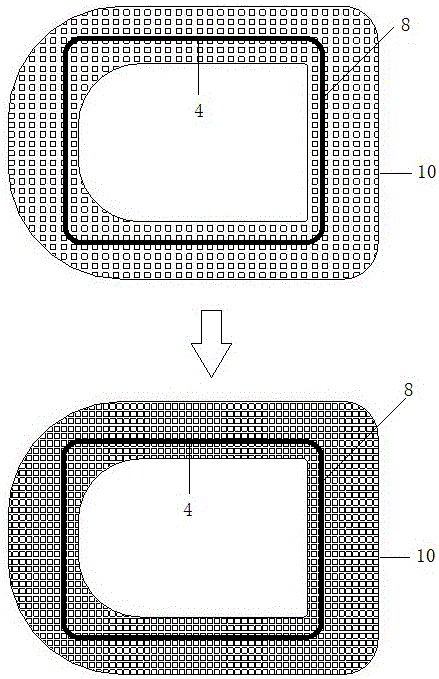

[0017] like figure 1 , figure 2 As shown, the toilet cover that can be automatically pasted includes a toilet cover 1; a toilet seat 2 is connected to the rotating shaft of the toilet cover 1; a toilet seat paper adhesive body 3 that matches the shape of the toilet seat 2 is attached to the inside of the toilet cover 1; the toilet seat The paper adhesive body 3 is formed by bonding a plurality of toilet seat papers; the middle part of the toilet seat paper has a gap matching the shape of the leak hole of the toilet seat 2; the adhesive layer 10 of the toilet seat paper is located side; from the outside to the inside, the adhesive force of the adhesive layer 10 of the toilet seat cushion paper increases successively; the backrest airbag 5 matching the shape of the leak hole is fixed in the middle of the toilet cover 1 inner side; the thickness of the backrest airbag 5 is greater than that of the toilet seat cushion paper. The thickness of the combined body 3 and the density o...

Embodiment 2

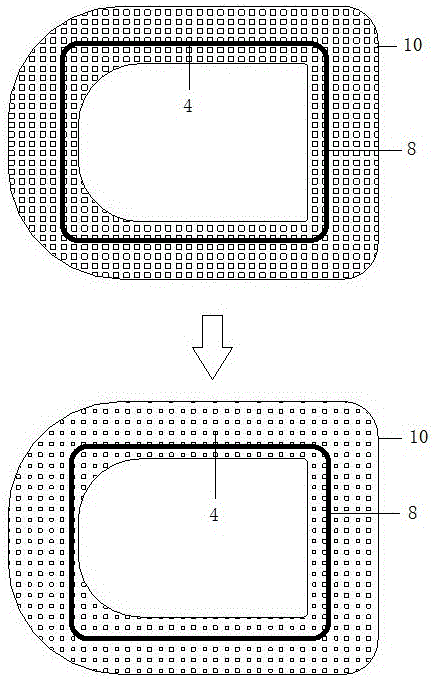

[0022] like image 3 As shown, the difference between this embodiment and embodiment 1 is that the colloidal particle 4 area of the adhesive layer 10 is changed sequentially to change the adhesive force between each layer of toilet seat paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com