Die blank printing assisting device

A technology of auxiliary device and mold base, which is applied in the field of typing equipment on the surface of the mold base, can solve the problems of inaccurate typing position, decreased physical strength of the operator, and long time consumption, etc., and achieve the effect of improving the quality of typing, improving efficiency, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

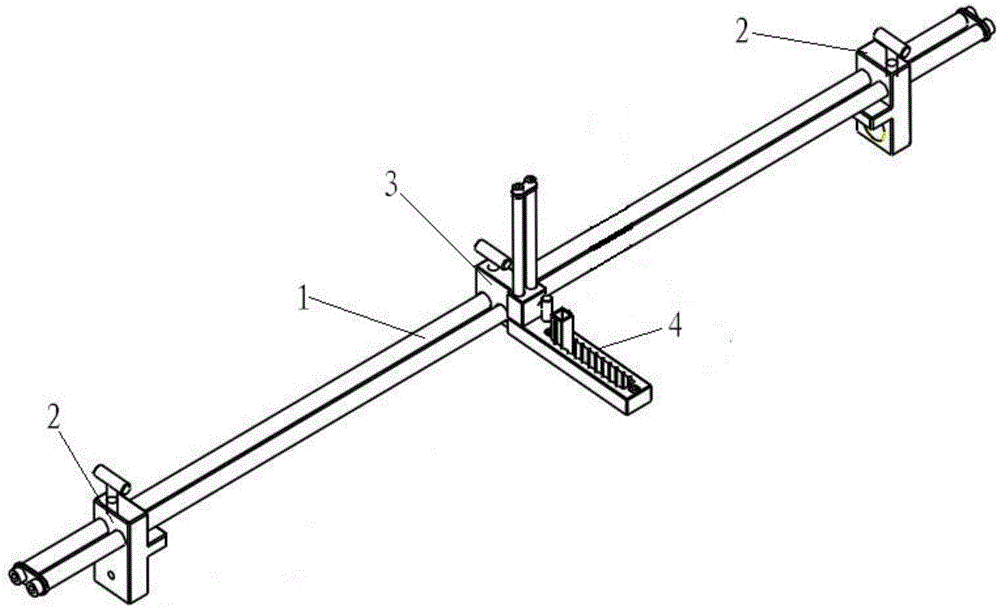

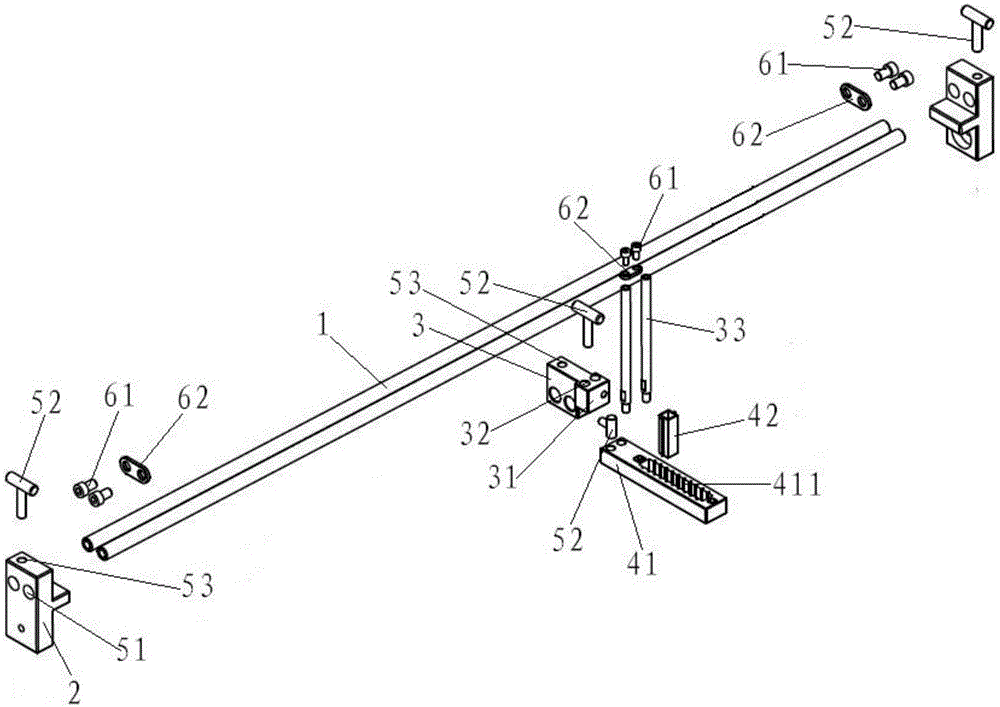

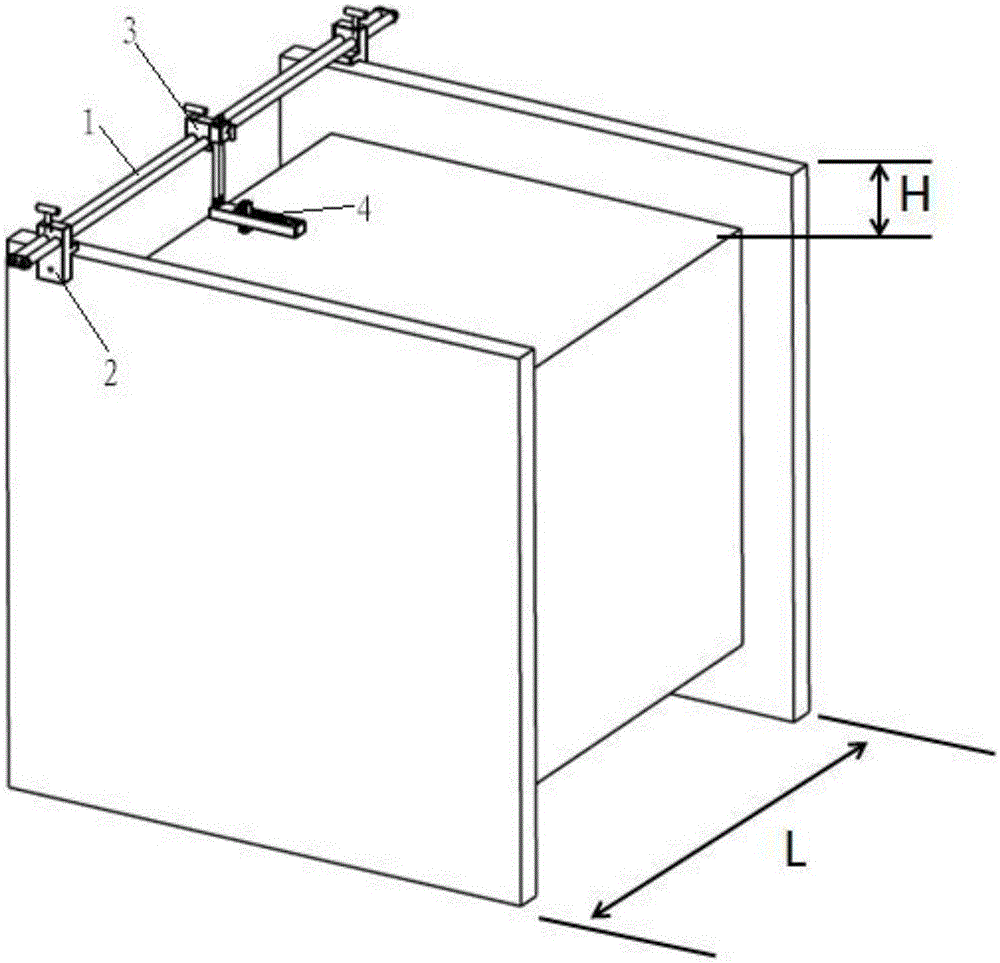

[0017] see Figure 1-3 As shown, the present invention relates to a mold blank typing aid, which includes a transverse guide rod 1, a fixed seat 2, a sliding seat 3, and 42 pieces 4 of character code sleeves, wherein the fixed seat 2 is slidably arranged on the transverse guide rod 1 The two ends are used to be fixed on the mold base, the slide seat 3 is slidably sleeved on the transverse guide rod 1, and the 42 pieces 4 of the character code sleeve are arranged on the slide base 3 so as to move up and down relative to the mold base Front end.

[0018] Compared with the existing technology, by setting the transverse guide rod 1, the fixed seat 2 and the sliding seat 3 which can slide along the transverse guide rod 1 are arranged on the transverse guide rod 1, and the word code sleeve is arranged on the slide seat 3 42 pieces 4, can be slid and adjusted according to the size of the mold base. The fixed seat 2 is fixed on the mold base, and slides and adjusts the slide seat 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com