Seat lifting mechanism

A lifting mechanism and seat technology, applied in the direction of movable seats, etc., can solve the problems of inconvenient lifting operation, unstable seat, unfavorable development and application of locomotives, vehicle driving seats, etc., and achieve good stability and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

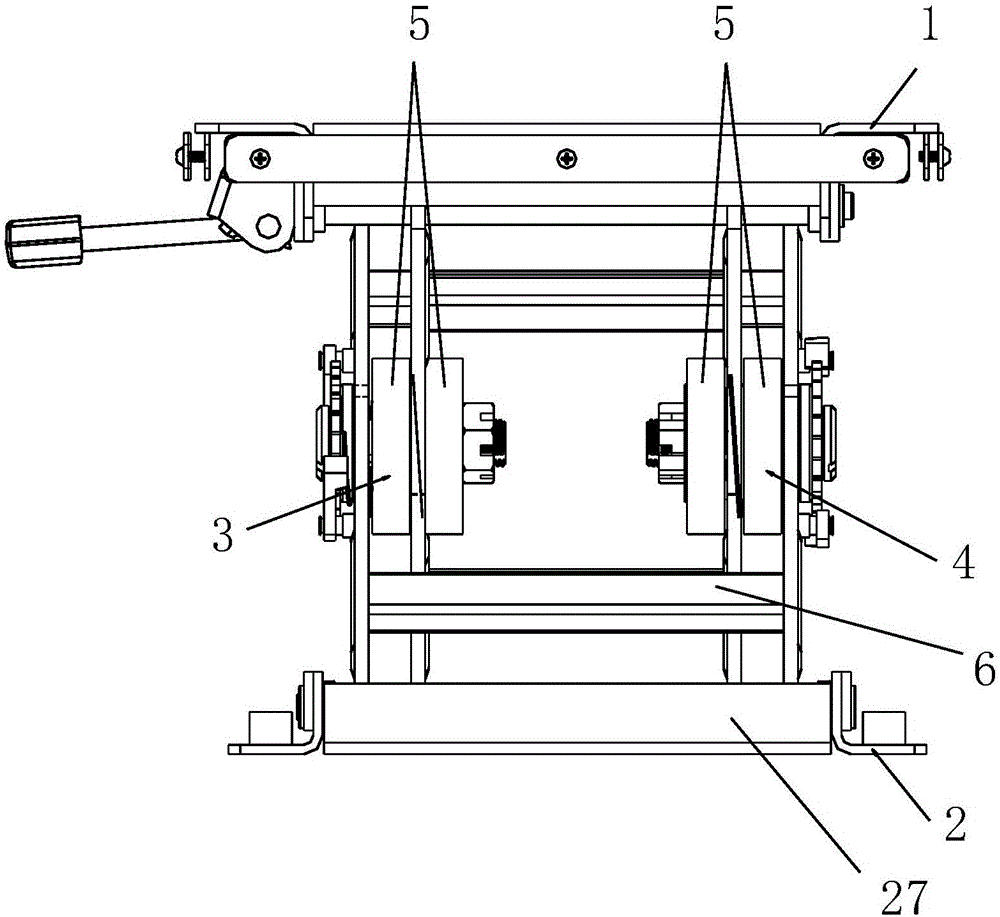

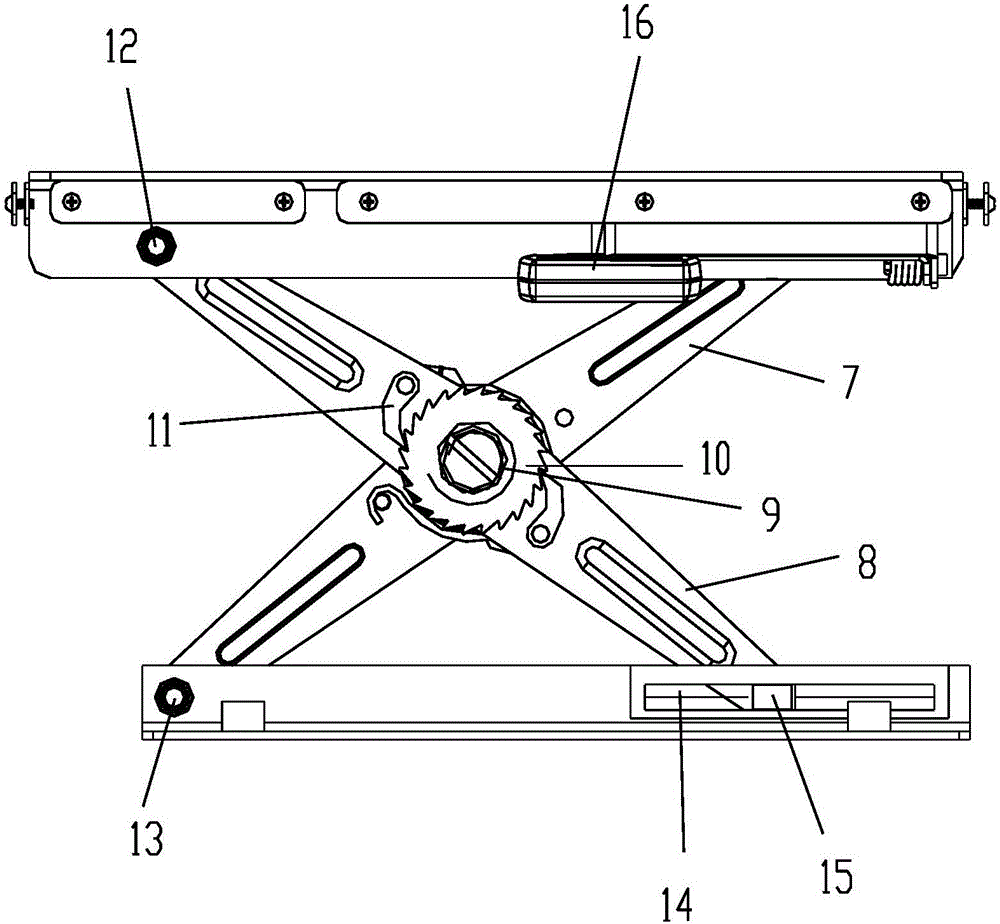

Embodiment 1

[0044] Such as Figure 1-5 , a seat lifting mechanism, comprising an upper bracket 1, a lower bracket 2, a left scissor frame 3 and a right scissor frame 4 located between the upper and lower brackets. The inner scissors plate 7, the outer scissors plate 8 are respectively provided with in the left and the right scissors frame, and the scroll spring shaft 9 that is contained in the inner and outer scissors plates and can rotate. The ratchet 10 is installed on the scroll spring shaft 9 and is located outside the outer scissor plate 8. The two scroll springs 5 are mounted on the scroll spring shaft 9 and are respectively located on both sides of the inner scissor plate 7 and one end is fixed on the scroll spring shaft 9. And the other end is fixed on the inner scissors board 7. Two upper sliding grooves 25 and two lower sliding grooves 14 are arranged on corresponding positions of the upper and lower brackets. Lower slider 15 is respectively housed in two corresponding chute...

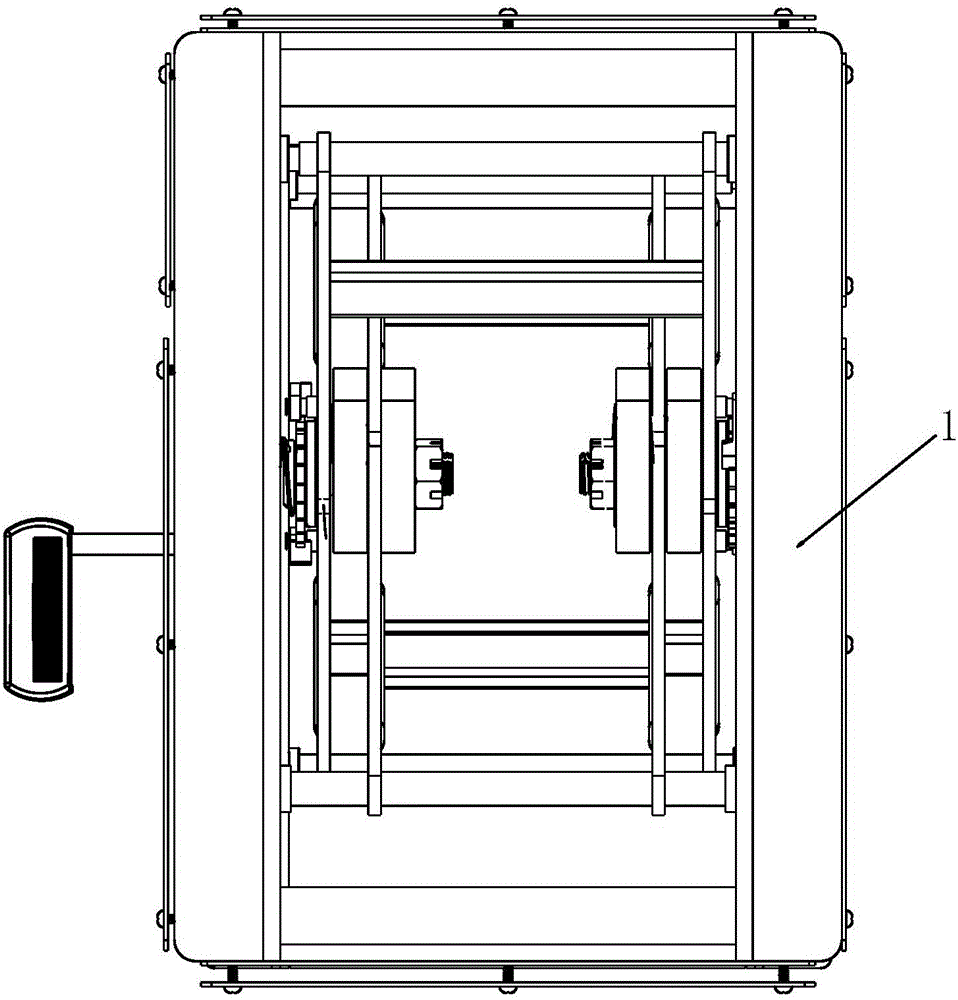

Embodiment 2

[0051] Such as Figures 9 to 13, a seat lifting mechanism, comprising an upper bracket 1, a lower bracket 2, a left scissor frame 3 and a right scissor frame 4 located between the upper and lower brackets. The inner scissors plate 7, the outer scissors plate 8 are respectively provided with in the left and the right scissors frame, and the scroll spring shaft 9 that is contained in the inner and outer scissors plates and can rotate. The ratchet 10 is installed on the scroll spring shaft 9 and is located inside the inner scissor plate 7. The two scroll springs 5 are mounted on the scroll spring shaft 9 and are respectively located on both sides of the inner scissor plate 7 and one end is fixed on the scroll spring shaft 9. And the other end is fixed on the inner scissors board 7. Two upper sliding grooves 25 and two lower sliding grooves 14 are arranged on corresponding positions of the upper and lower brackets. Lower slider 15 is respectively housed in two corresponding ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com