Railway wagon overhauling production line without crown block and overhauling process thereof

A technology for railway freight cars and production lines, applied in railway car body parts, railway auxiliary equipment and other directions, can solve problems such as messy process layout and impact on workshop safety, achieve good market promotion value, high maintenance efficiency, and avoid equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

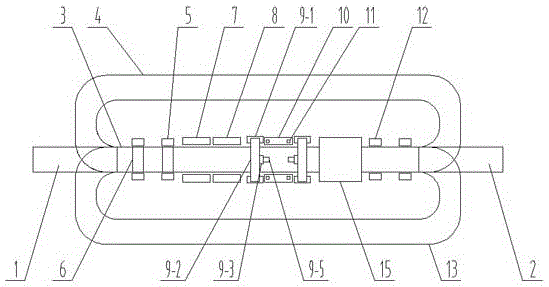

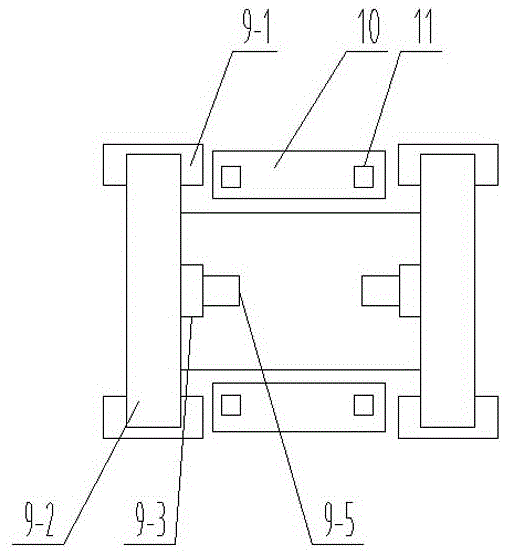

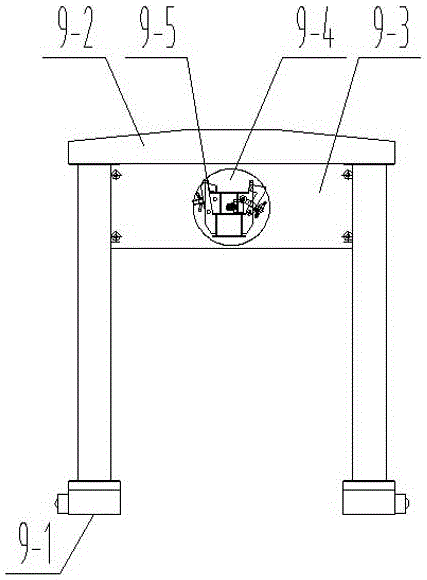

[0018] Such as figure 1 , 2 , 3, the present invention includes a truck inspection and repair entry line 1 and a truck delivery line 2, and it also includes an inspection and repair standard railway track 3, a track switch 4, a bogie replacement station, a damaged part damage and disassembly station, Turn over the inspection station, inspection and shaping station and bogie reinstallation station. The switch device is connected to both ends of the maintenance standard railway track 3. The bogie replacement station is composed of an electric linkage crane unit 5 and a group of remote-controlled electric maintenance trolleys 6. The base of the electrical linkage crane unit 5 is fixed on the The overhaul standard railway track 3 is located on both sides of one end of the truck overhaul entry line 1. A group of remote-controlled electric overhaul trolleys 6 respectively walk on the overhaul standard railway track 3. The damaged parts are determined and disassembled by a pair of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com