Canning and discharging device

A discharge device and a technology for loading and discharging materials, applied in packaging, liquid materials, transportation and packaging, etc., can solve the problems of difficult filling, high viscosity, poor fluidity, etc., and achieve fast glue discharge and high filling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

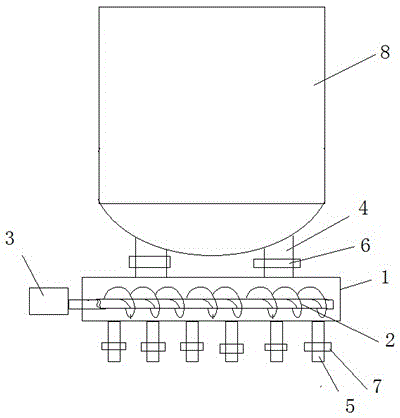

[0010] A canned discharging device includes a stirring chamber 1, which communicates with the bottom of a tank body 8 through two connecting pipes 4, and the tank body is in the shape of a barrel. A control valve 6 is provided on the connecting pipe. A stirring device 2 is arranged in the stirring chamber, and the stirring device is a screw rod. The stirring device is connected with the motor 3; a group of discharge pipes 5 are arranged at the lower part of the stirring chamber. A switch 7 is provided on the discharge pipe. A connecting flange for canning is provided on the discharge pipe. The flow rate of the two connecting pipes is suitable for a set of discharge pipes.

[0011] The invention stirs the viscous rubber material into a highly fluid rubber material through the screw rod, realizes material discharge through the discharge pipe, has fast glue discharge speed and high filling efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com