Full-automatic glue dispensing machine

A gluing machine, fully automatic technology, applied in the field of gluing machines, can solve the problems of high labor intensity, high cost of manpower and material resources, unsatisfactory gluing effect, etc., to improve market competitiveness, low production cost, Glue effect ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

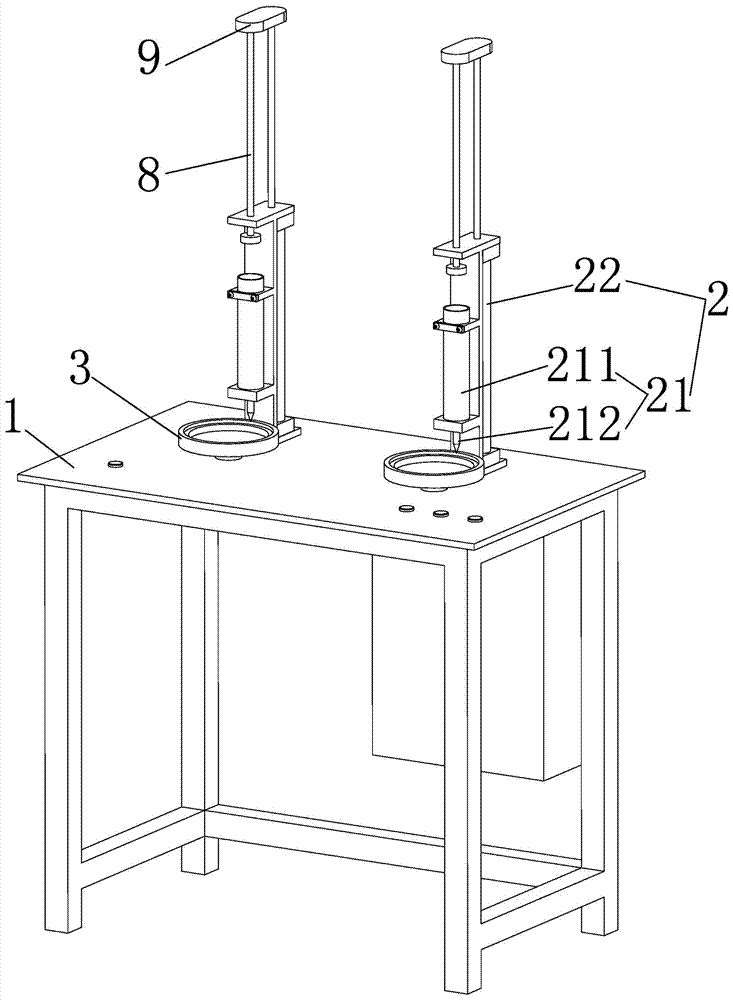

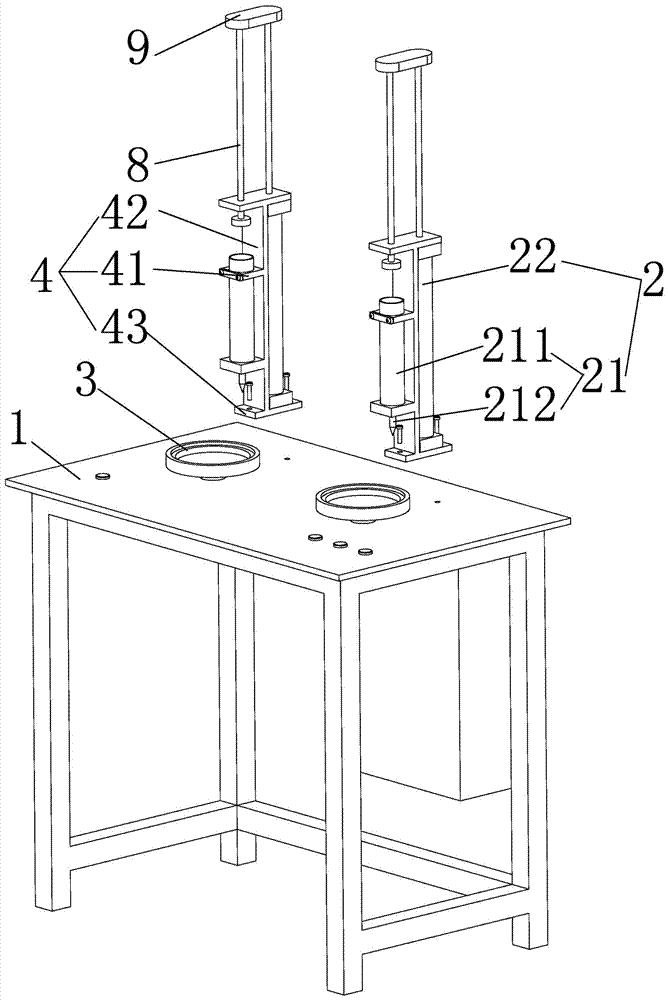

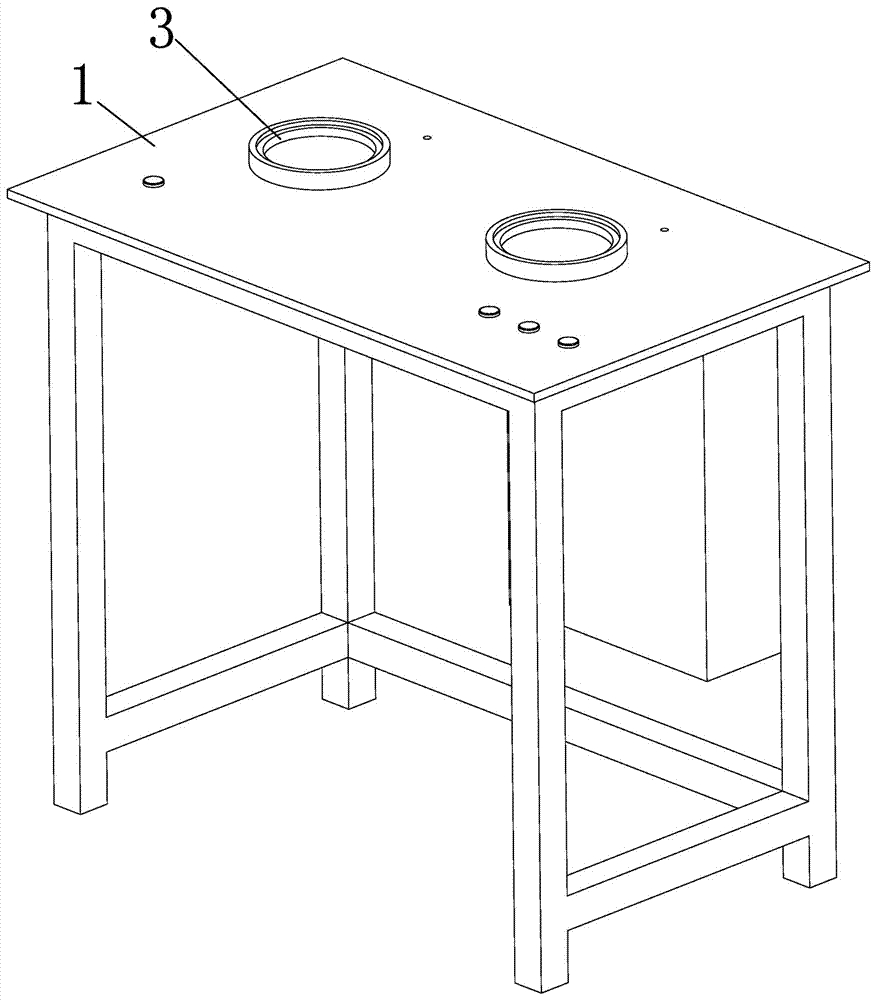

[0015] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A fully automatic gluing machine, characterized in that it includes a working table 1, a gluing machine 2 and a working disc 3 arranged above the working table 1, and the working disc 3 is connected to a servo motor located below the working table 1, and by starting the servo The motor drives the working disc 3 to rotate; the glue machine 2 includes a glue barrel 21 and a cylinder 22 located behind the glue barrel 21. The barrel 21 is connected to the front and back of the cylinder 22 through the connecting frame 4, the connecting frame 4 is provided with a threaded hole 5, the fixing screw passes through the threaded hole 5 and is screwed to the workbench 1, and the glue machine 2 is connected to the workbench 1; The glue barrel 21 includes a colloid accommodation chamber 211 and a glue nozzle 212 located below the colloid accommodating chamber 211. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com