Automatic glue dispenser

A dispensing machine and automatic technology, applied in the field of dispensing machines, can solve problems such as low accuracy, error-prone, complicated manual dispensing operations, etc., and achieve the effect of convenient debugging and stable glue output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

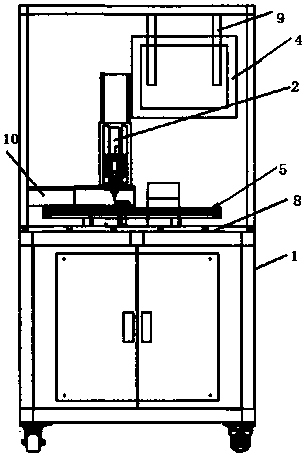

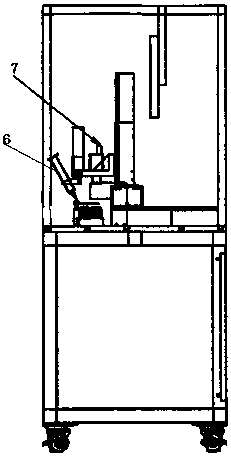

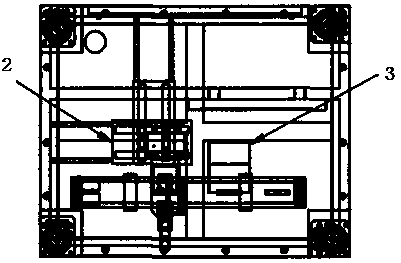

[0020] Such as figure 1 An automatic glue dispensing machine is shown, including a body 1, a four-axis arm 2, a UV lamp 3, a display screen 4, a belt flow channel 5, a glue dispenser 6, a CCD digital camera 7, a carrying platform 8, a connecting plate 9, Pressing plate 10, the middle position of the body body 1 is provided with a bearing platform 8, the bearing platform 8 is provided with a belt runner 5, and the belt runner 5 moves 20 cm every 6 seconds, and the belt runner is an induction motor belt Runner, the maximum moving speed of the motor: 100mm / sec, a pressure plate 10, a glue dispenser 6 and a UV lamp 3 are arranged above the belt flow channel 5, the irradiation power of the UV lamp is 30%, and the pressure plate 10 will reduce the pressure Press the product, the dispenser 6 is connected to the four-axis arm 2, the dispenser has the function of vacuum suction, and the glue output time of the dispenser is 30 seconds, the rear of the dispenser 6 is provided with CCD d...

Embodiment 2

[0035] Such as figure 1 An automatic glue dispensing machine is shown, including a body 1, a four-axis arm 2, a UV lamp 3, a display screen 4, a belt flow channel 5, a glue dispenser 6, a CCD digital camera 7, a carrying platform 8, a connecting plate 9, Pressing plate 10, the middle position of the body body 1 is provided with a bearing platform 8, the bearing platform 8 is provided with a belt runner 5, and the belt runner 5 moves 20cm every 6 seconds, and the belt runner is an induction motor belt Runner, the maximum moving speed of the motor: 100mm / sec, a pressure plate 10, a glue dispenser 6 and a UV lamp 3 are arranged above the belt flow channel 5, and the irradiation power of the UV lamp is 80%, and the pressure plate 10 will reduce the pressure Press the product, the dispenser 6 is connected to the four-axis arm 2, the dispenser has the function of vacuum suction, and the dispenser has a glue output time of 80 seconds, and the rear of the dispenser 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com