Reciprocating compressor and household appliance

A technology for household appliances and compressors, which is applied in the field of compressors, and can solve problems such as the growth of the compressor's rotating crankshaft, the increase in the volume of the rotating mechanism, and the decrease in the operating frequency of the piston, so as to achieve fast suction and exhaust speeds and increase the effective suction. The effect of air volume and inspiratory volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

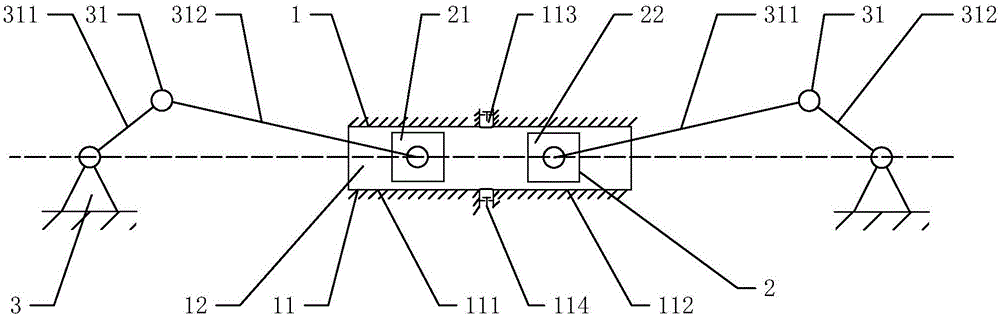

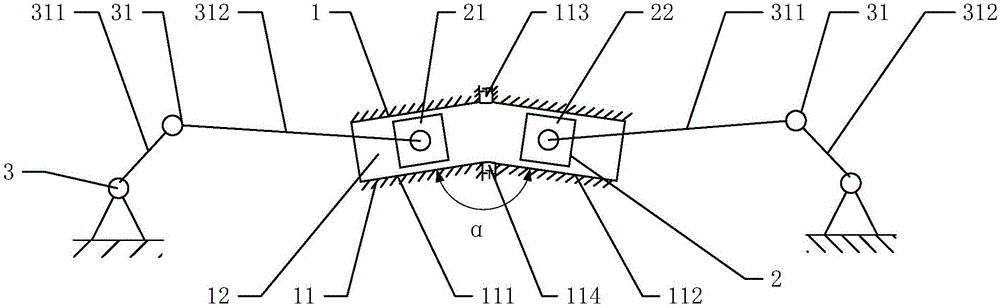

[0022] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0023] Such as figure 1 As shown, the reciprocating compressor in this application includes a cylinder 1 , a piston 2 and a power mechanism 3 . The cylinder 1 includes a cylinder body 11, a cylinder cavity 12 is formed in the cylinder body 11, the piston 2 is located in the cylinder cavity 12, and can slide along the cavity wall of the cylinder cavity 12; The power mechanism 3 is connected with the piston 2 for driving the piston 2 to slide in the cylinder cavity 12 .

[0024] Each cylinder 1 is provided with two pistons 2, including a first piston 21 and a second piston 22; the cylinder block 11 of each cylinder 1 forms a first cylinder that cooperates with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com