Self Complementary Automobile Steering Mechanism

A steering mechanism and automobile technology, applied in mechanical equipment, rigid brackets of bearing components, bearing components, etc., can solve the problems of short service life of bushings, failure of bushings to automatically compensate for wear gaps, frequent replacements, etc., and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

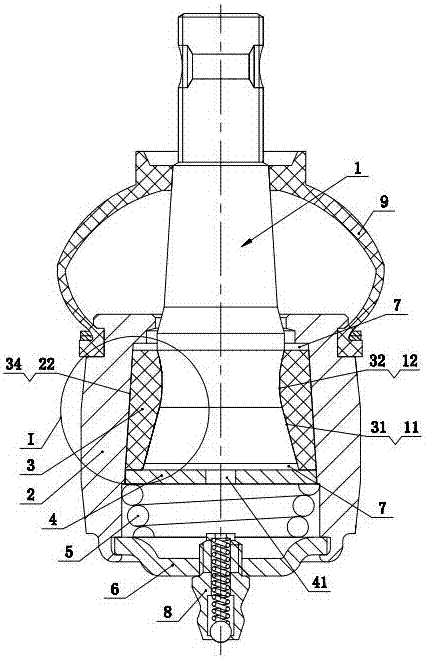

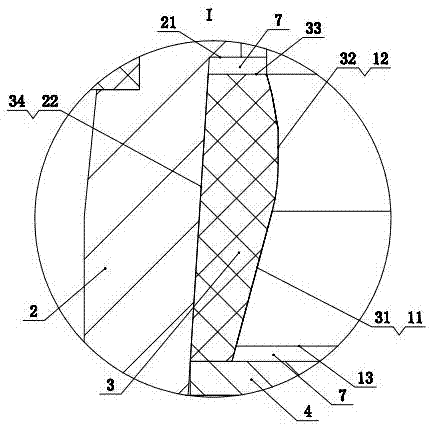

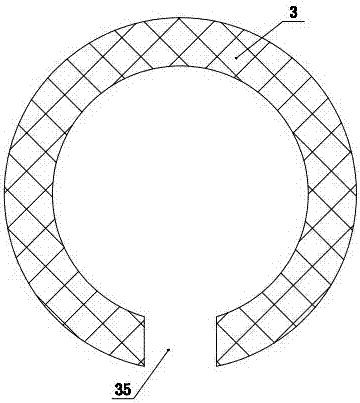

[0014] like figure 1 , 2 , 3 shows a self-complementary automobile steering mechanism, including a rotating shaft 1 and a shaft sleeve 2, and a bushing is arranged between the axial rear end of the rotating shaft 1 located in the shaft sleeve 2 and the shaft sleeve 2 3. The axial front end of the rotating shaft 1 located outside the sleeve 2 is connected with a driving mechanism to drive it to swing. The inner ring surface of the bushing 3 is composed of an inner tapered surface 31 with a narrow inside and a wide outside and a radial The arc-shaped surface 32 bowed inward is connected, and the inner tapered surface 31 is correspondingly located at the axial rear end, the arc-shaped surface 32 is correspondingly located at the axial front end, and the axial rear end of the rotating shaft 1 is Correspondingly, the tapered portion 11 fitted with the inner tapered surface 31 and the arc-shaped portion 12 fitted with the arc-shaped surface 32 are provided, and the axial rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com