High-speed train shaft-mounted brake disc with slider structure

A technology for high-speed trains and brake discs, applied in the direction of brake discs, etc., can solve the problems of increasing bolts, brake disc bolt breakage, and reducing the cost of brake discs, so as to reduce costs, reduce the risk of bolt fatigue fracture, and manufacture Safe and reliable dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

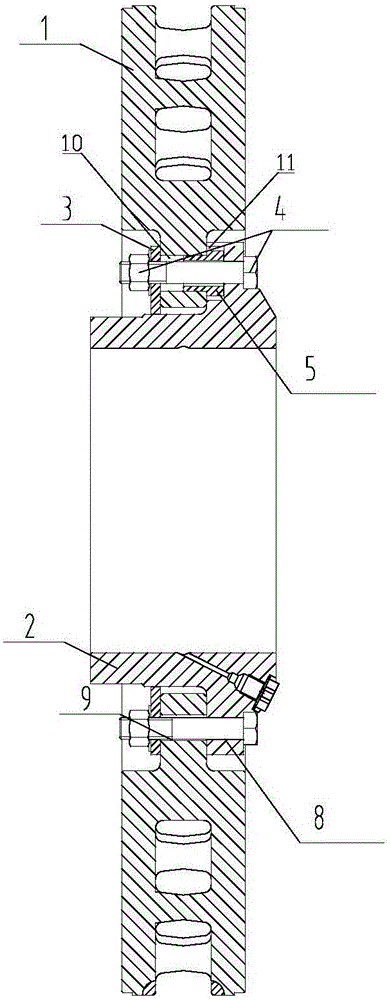

[0019] A high-speed train shaft-mounted brake disc with a slider structure, including a disc body 1, a disc hub 2, a pressure plate 3 and a fastener 4. There are 9 equally circumferentially distributed teeth on each of the disc body 1 and the disc hub 2, and each There are mounting holes on the teeth. The mounting holes include bolt holes and slider holes; multiple slider holes are arranged at intervals with the bolt holes. Such as figure 1 As shown, the bolt holes 8 on the bottom and the bolt holes 9 on the hub are aligned and fixed by fasteners 4; the holes on the top are the slider holes, which are used to install the slider 5.

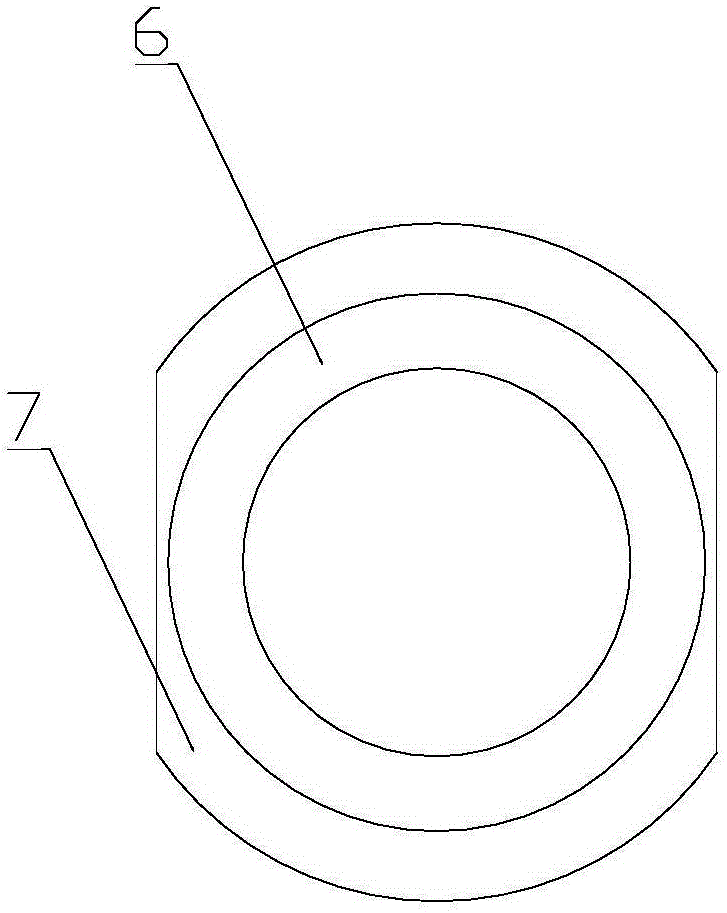

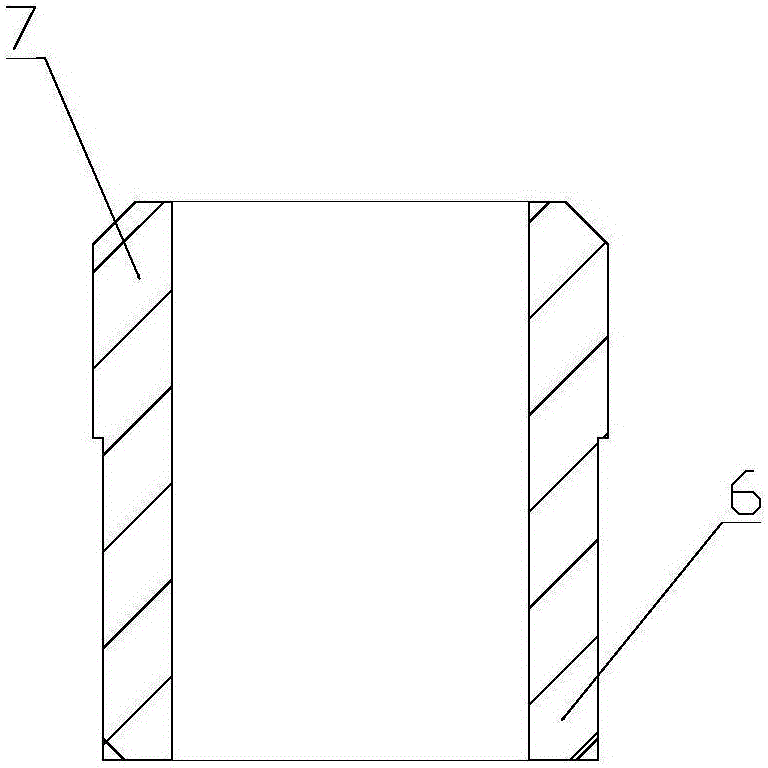

[0020] The slider 5 includes an upper end 6 and a lower end 7, the upper end 6 and the lower end 7 are concentric stepped cylindrical shaft structures, the slider 5 has a through hole passing through the upper end 6 and the lower end 7, and the outer diameter of the upper end 6 is less than The outer diameter of the lower end 7. The size of the ...

Embodiment 2

[0024] The difference from Embodiment 1 is that the lower end 7 of the slider is cylindrical. Correspondingly, the shape of the hub slider hole 11 needs to match the structural change of the lower end portion 7 accordingly, and is a cylindrical hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com