Supercharging test apparatus and use method thereof

A test device and hydraulic testing machine technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large structure, large water intake, and low efficiency of hydraulic presses, so as to reduce the internal cross-sectional area and improve the efficiency. , the effect of reducing the overall time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

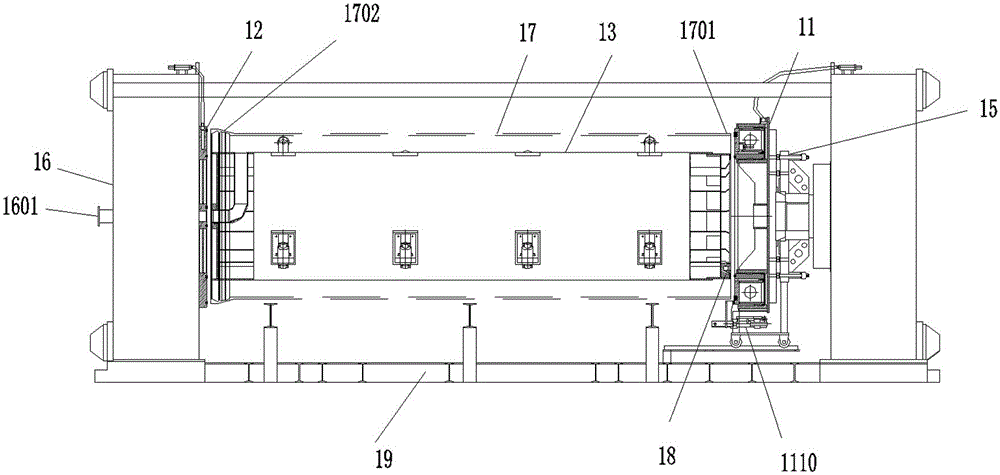

[0032] see figure 1 As shown, a pressurization test device includes a socket floating seal assembly 11, a socket seal assembly 12 and an inner liner 13. The socket floating seal assembly 11 is installed on a hydraulic testing machine push head 15, and the socket seal The assembly 12 is installed on the fixed retaining wall 16 at one end of the hydraulic testing machine 19, and the liner 13 is installed in the cavity of the pipe material 17 to be tested.

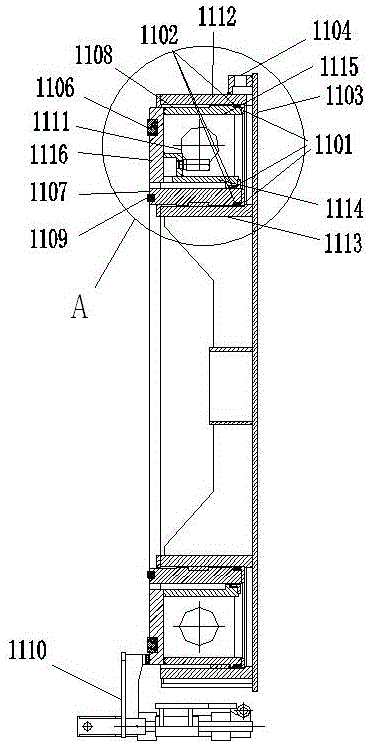

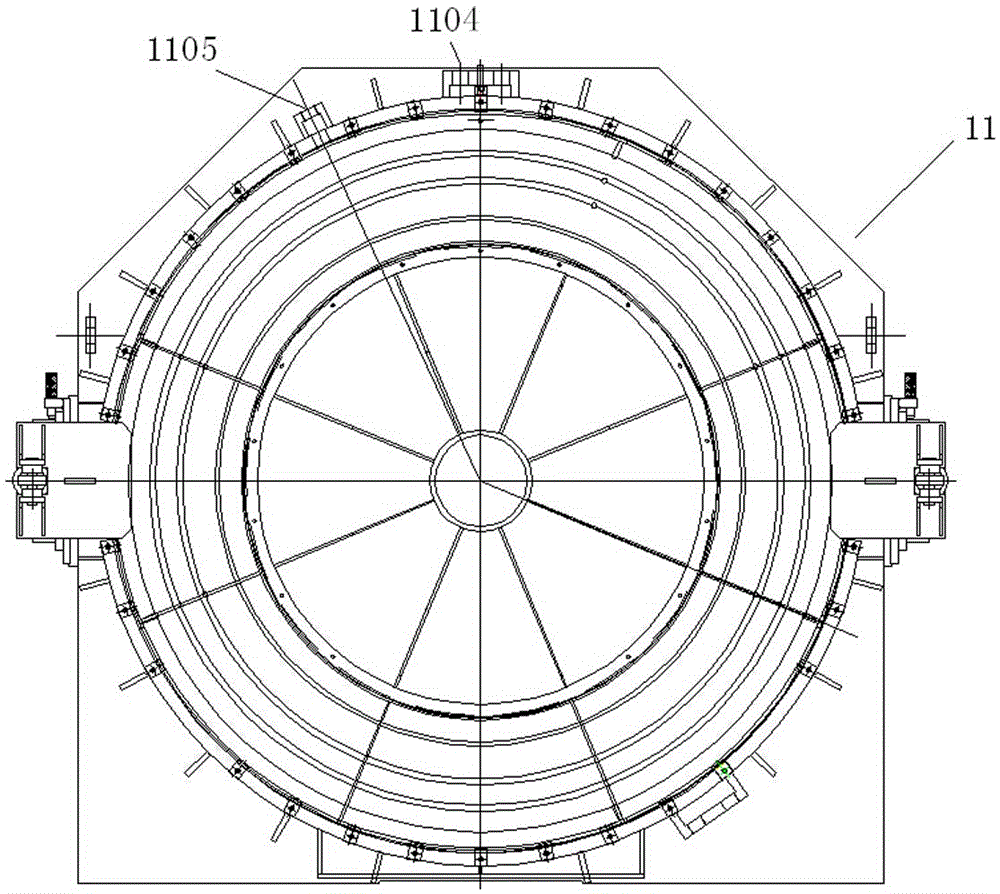

[0033] see Figure 2-Figure 4, the socket floating seal assembly 11 includes a floating seal bottom plate 1103, an annular guide plate 1113, an annular guide plate 2 1112, an annular floating seal plate 1 1107, an annular floating seal plate 2 1108, a one-way valve 1111, and an annular guide plate 1113 and annular guide plate two 1112 are fixedly connected with the floating sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com