Integrated distribution box for onu equipment and optical splitter

A technology of optical splitter and wiring box, applied in the direction of fiber mechanical structure, etc., can solve the problems of uneven construction technology, various installation methods, and difficult to comb, so as to simplify the optical cable fusion process, improve the operability of the box, and improve the work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

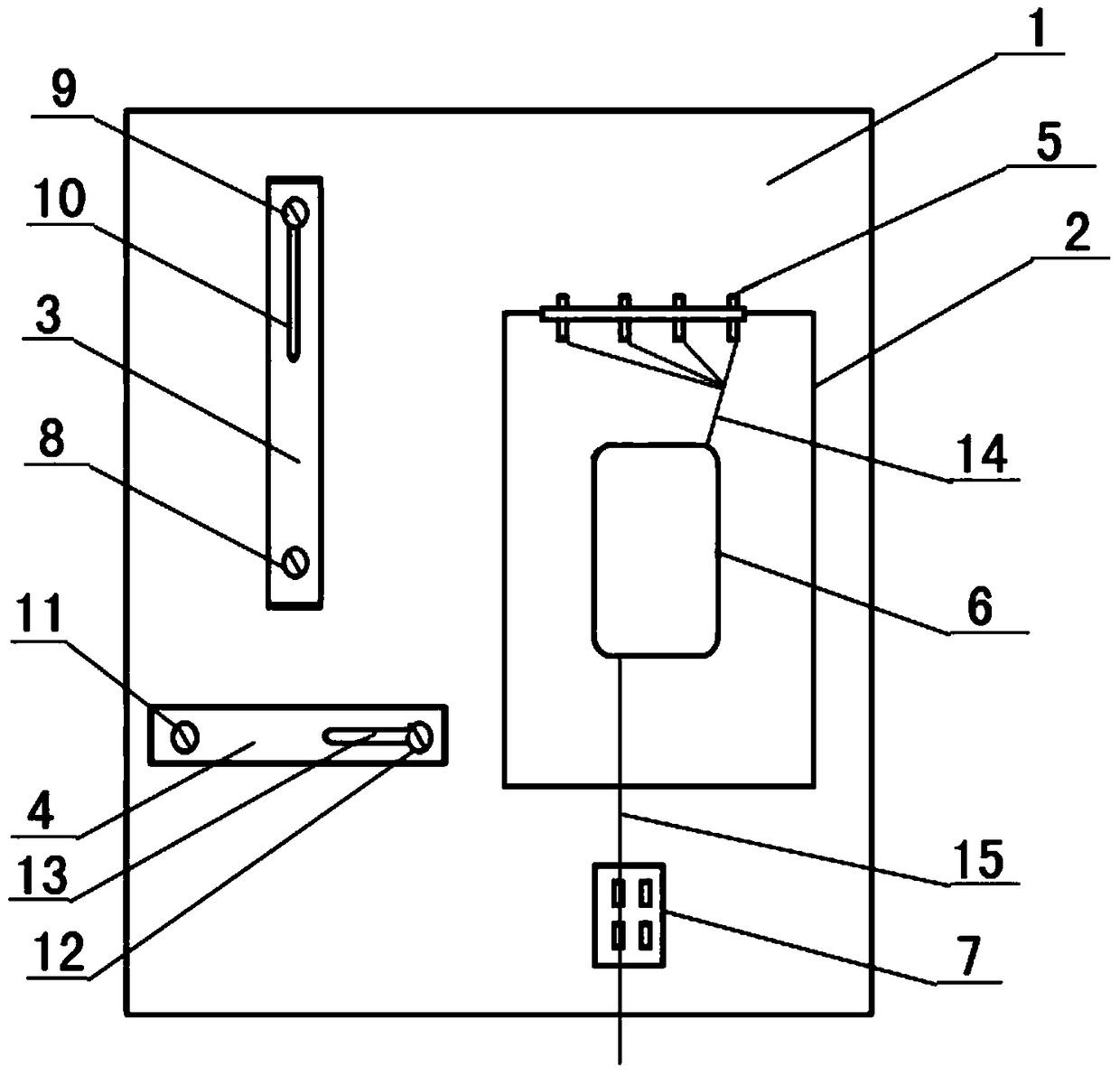

[0039] Such as figure 1 Shown, a kind of integrated wiring box of ONU equipment and light splitter, it comprises backboard 1, two sideboards, bottom board, top board and box door, and described side board is all provided with the radiating hole of louver structure, described The base plate is provided with an optical cable through hole, and the back plate 1 is provided with an optical cable terminal box 2, at least one pair of first connection bolts for fixing the ONU equipment and at least one pair of second connection bolts for fixing the optical splitter. The first connection bolt and the second connection bolt are located on the same side of the optical cable terminal box 2,

[0040] A first fixed splint 3 is sleeved on each pair of the first connecting bolts, and the first fixed splint 3 slides along the axial direction of the first connecting bolts, and each of the first connecting bolts is also provided with a first An adjustment thread and a first adjustment nut match...

Embodiment 2

[0044] Such as figure 1 Shown, a kind of integrated wiring box of ONU equipment and light splitter, its structure, installation method are similar to embodiment 1, and difference is that every pair of described first connection bolts is divided into the first fixed connection bolt 8 and can Close to or away from the first movable connection bolt 9 of the first fixed connection bolt 8, the first fixed connection bolt 8 is fixedly connected with the backboard 1, and the backboard 1 is provided with the first movable connection bolt 9. The first backboard bar hole that the connecting bolt 9 matches, the first movable connecting bolt 9 is bolted to the backboard 1 through the first backboard bar hole, and the first fixed splint 3 is provided with There is a first splint bar-shaped hole 10 that matches the first movable connection bolt 9, and each pair of the second connection bolts is divided into a second fixed connection bolt 11 and a second fixed connection bolt 11 that can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com