Refining process and device for crude methanol

A process device and crude methanol technology, applied in separation methods, chemical instruments and methods, preparation of hydroxyl compounds, etc., to achieve the effects of convenient construction, flexible parameter control, and reduced quantity, such as old process transformation and equipment layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

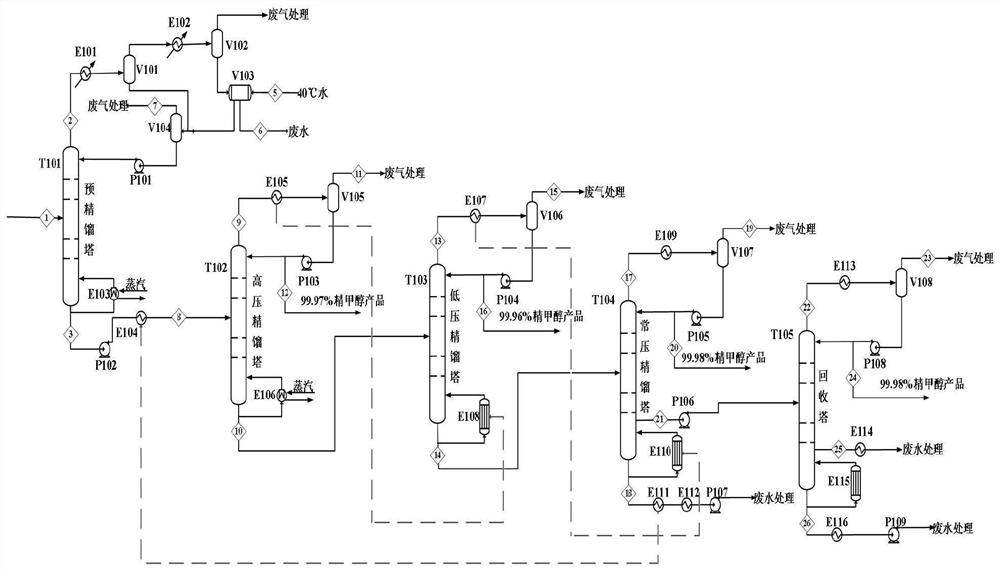

[0080] see figure 1 , a crude methanol refining process device, comprising: a pretreatment unit, a high-pressure treatment unit, a low-pressure treatment unit, an atmospheric pressure treatment unit and a recovery treatment unit;

[0081] The pretreatment unit, high pressure treatment unit, low pressure treatment unit, normal pressure treatment unit and recovery treatment unit are connected in sequence;

[0082] Wherein, the pretreatment unit includes: the pre-rectification tower T101, the first condensing unit, the first reboiler E103, the first bottom transfer pump P102 and the heat exchanger E104; the top of the pre-rectification tower T101 and the first condensing Unit connection; the bottom of the pre-distillation tower T101 is divided into two branches, one is connected with the first reboiler E103, and the other is connected with the first bottom transfer pump P102, heat exchanger E104 and high-pressure processing unit in sequence ;

[0083] The high-pressure treatmen...

Embodiment 2

[0103] Such as figure 1 Shown in (dotted line represents heat flow through direction), a kind of crude methanol refining process method, adopts the processing device that embodiment 1 provides, specifically comprises the following steps:

[0104] (1) Crude methanol (40°C, 0.57MPa, 31244kg / h) enters the pre-distillation tower T101, passes through 51 trays or several stages of full gas-liquid contact, and a small amount of light components and gaseous methanol are extracted from the top of the tower Enter the first flash tank V101 through the first condenser E101, and the gas phase obtained by the flash continues to enter the second flash tank V102 through the second condenser E102 for gas-liquid separation, and the non-condensable gas (37.78°C, 0.13MPa) is discharged, and the liquid phase Enter the phase separator V103, the liquid phase of light components and impurities is discharged to wastewater treatment, the liquid phase of crude methanol is mixed with the liquid phase str...

Embodiment 3

[0110] like figure 1 As shown, a crude methanol refining process, using the process device provided in Example 1, specifically comprises the following steps:

[0111] (1) Crude methanol (40°C, 0.57MPa, 31244kg / h) enters the pre-distillation tower T101, passes through 54 layers of trays or several stages of full gas-liquid contact, and a small amount of light components and gaseous methanol are extracted from the top of the tower Enter the first flash tank V101 through the first condenser E101, and the gas phase obtained by the flash continues to enter the second flash tank V102 through the second condenser E102 for gas-liquid separation, and the non-condensable gas (37.79°C, 0.12MPa) is discharged, and the liquid phase Enter the phase separator V103, the liquid phase of light components and impurities is discharged to wastewater treatment, the liquid phase of crude methanol is mixed with the liquid phase stream in the first flash tank V101, and enters the first tower top reflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com