A kind of continuous production process and device of amino acid methyl ester

A technology of amino acid methyl ester and production process, which is applied in the chemical industry, sustainable manufacturing/processing, organic chemistry, etc., can solve the problems of large loss of methanol, large amount of anhydrous methanol, and high yield, so as to reduce the amount of consumption and reduce the concentration The effect of distillation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

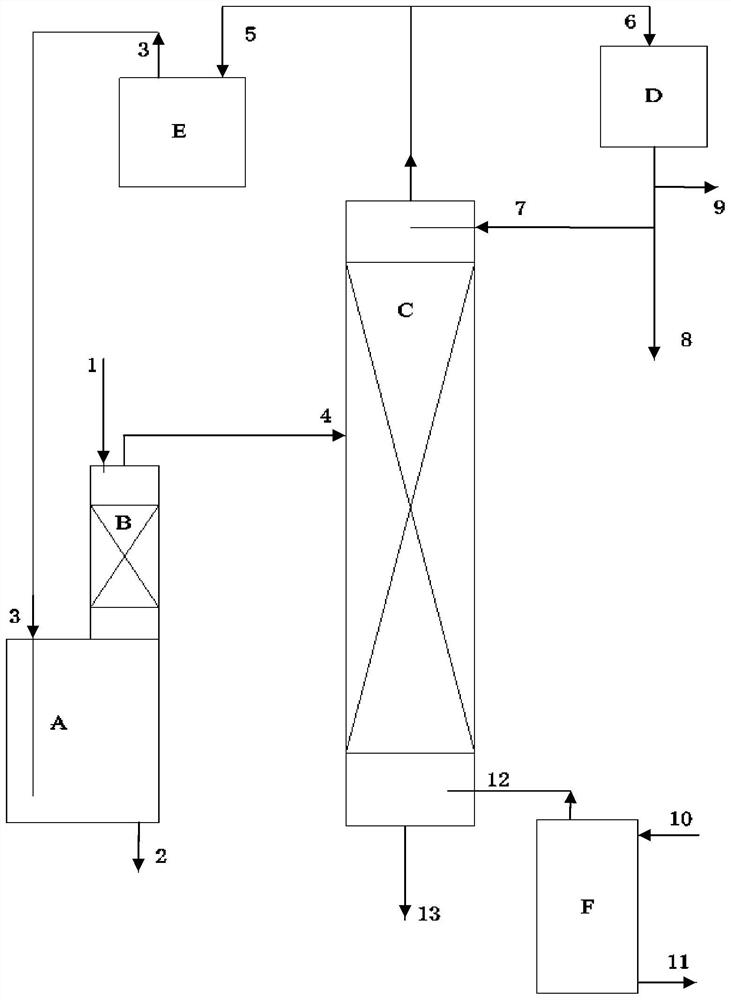

[0034] P-Hydroxyphenylglycine, sulfuric acid and methanol are mixed in a ratio of 1:1.1:5 and heated to 80 °C to dissolve, and the solution continuously enters the top of amino acid methyl esterification tower B through pipeline 1 at a flow rate of 1100kg / h , enter the tower kettle A through the packed tower body, and at the same time feed 3000kg / h of anhydrous methanol steam from the pipeline 3 to the lower part of the tower kettle A, maintain the tower kettle temperature of 82°C, the top temperature of 80°C, and the aqueous methanol vapor of 3100kg / h. Pipeline 4 enters the middle of rectifying tower C, and part of the anhydrous methanol vapor at the top of the tower enters Roots compressor E through pipeline 5, and is compressed and discharged into pipeline 3, and the rest of the anhydrous methanol vapor enters reflux condenser D through pipeline 6, The 2000kg / h condensate is returned to the top of the rectification tower C through the pipeline 7, and the reflux rate is contr...

Embodiment 2

[0036] P-Hydroxyphenylglycine, sulfuric acid and methanol are mixed in a ratio of 1:1.1:5 and heated to 80 °C to dissolve, and the solution continuously enters the top of amino acid methyl esterification tower B through pipeline 1 at a flow rate of 1100kg / h , enter the tower kettle A through the packed tower body, and at the same time feed 2000kg / h of anhydrous methanol steam from the pipeline 3 to the lower part of the tower kettle A, maintain the tower kettle temperature of 82°C, the top temperature of 80°C, and the aqueous methanol vapor of 2100kg / h. Pipeline 4 enters the middle of rectifying tower C, and part of the anhydrous methanol vapor at the top of the tower enters Roots compressor E through pipeline 5, and is compressed and discharged into pipeline 3, and the rest of the anhydrous methanol vapor enters reflux condenser D through pipeline 6, The 2000kg / h condensate is returned to the top of the rectification tower C through the pipeline 7, and the reflux rate is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com