Ring-shaped nozzle of heat gun

A ring-shaped spray head and hot air gun technology, applied in the direction of spray device, spray device, etc., can solve the problems of affecting output, heat waste, time-consuming and laborious, etc., and achieve the effect of easy installation and disassembly, reasonable structure design, and time reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

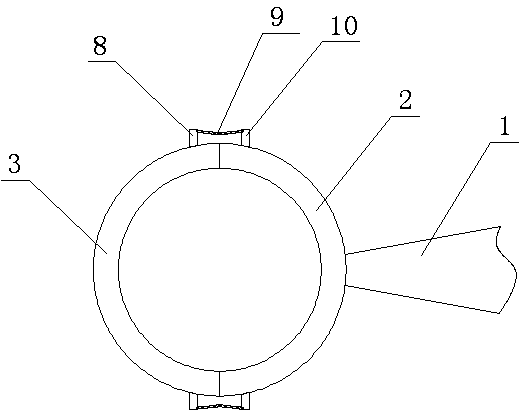

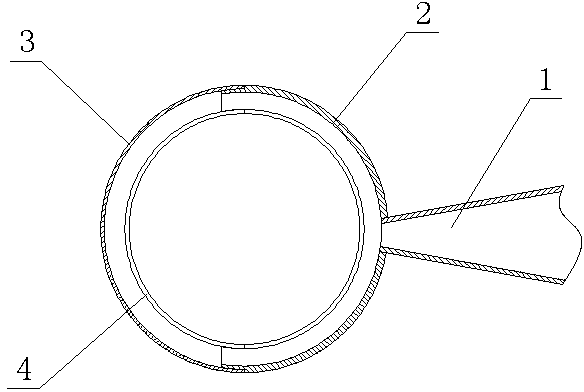

[0017] The annular nozzle of the hot air gun of the present invention is to connect the annular nozzle at the outlet of the straight cone type nozzle 1 of the heat gun, and the annular nozzle is composed of a semi-annular nozzle I2 and a semi-annular nozzle II3, such as figure 1 As shown, the center of the semi-annular nozzle I2 is connected to the straight cone nozzle 1 of the heat gun; the inner ring surfaces of the semi-annular nozzle I2 and the semi-annular nozzle II3 are both provided with an annular air outlet I4, and the gap width of the annular air outlet I4 is 0.3 ~ 1.5mm.

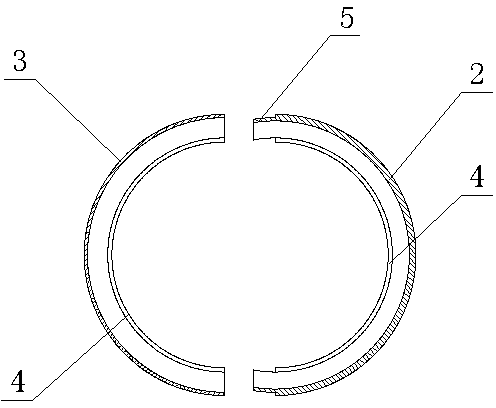

[0018] The annular nozzle is composed of semi-annular nozzle I2 and semi-annular nozzle II3, such as figure 2 , image 3 As shown, that is, the two ends of the semi-annular nozzle I2 are connected with an open annular connection part 5, such as Figure 5 As shown; the annular connection part 5 is inserted into the two ends of the semi-circular sprinkler II 3, such as Image 6 As shown, the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com