Line number identification system and method

A technology for identifying systems and line numbers, applied in instruments, inductive record carriers, data processing applications, etc., can solve problems such as low efficiency and difficulty in finding, achieve efficient access, improve order management and processing efficiency, and quickly identify Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

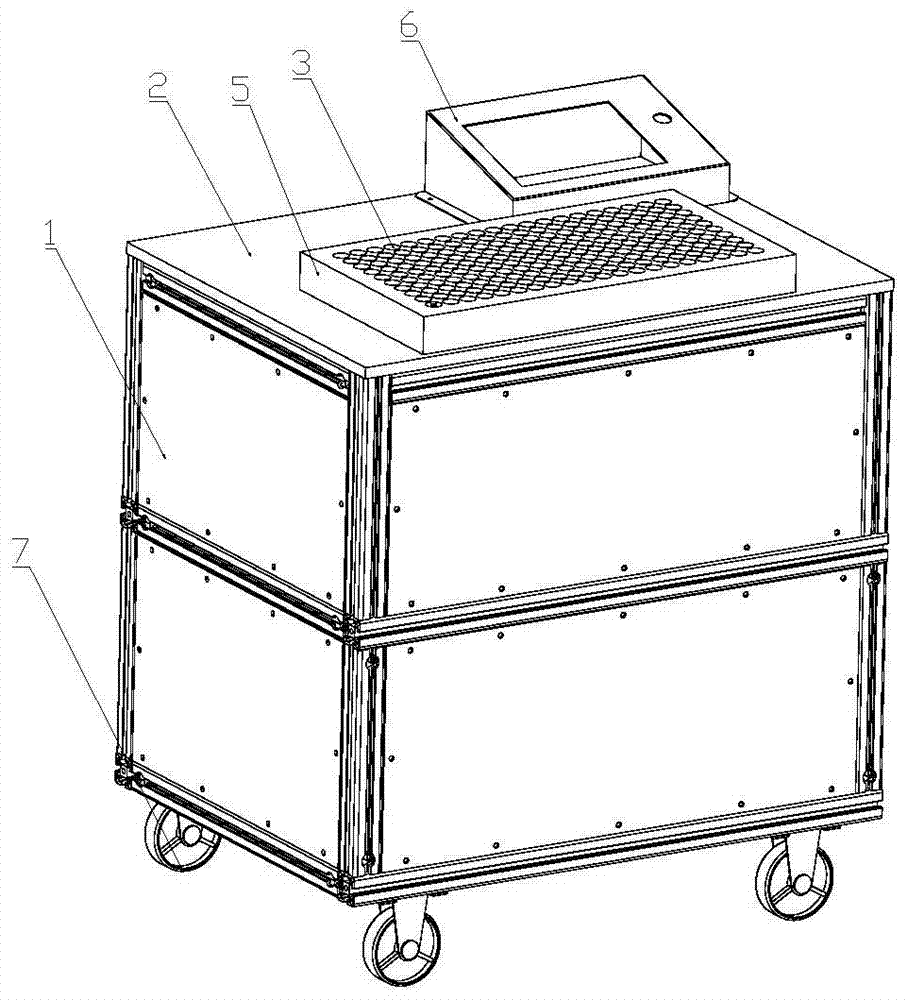

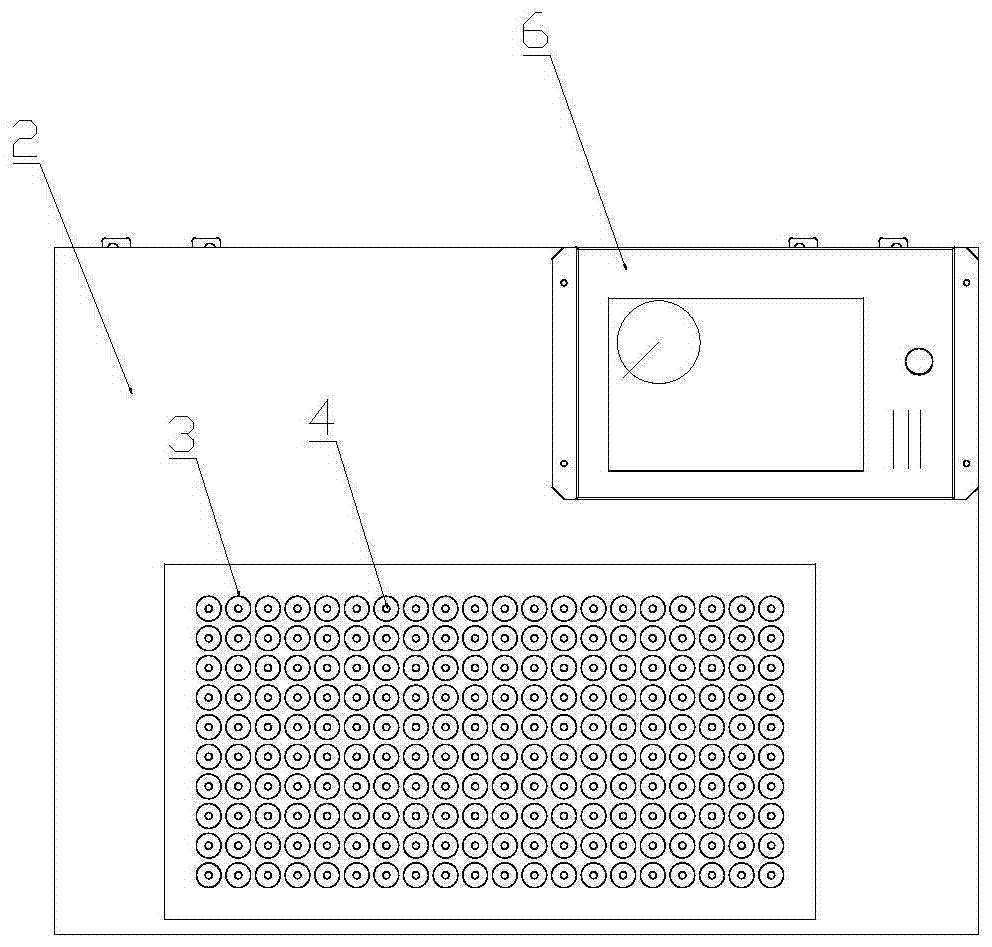

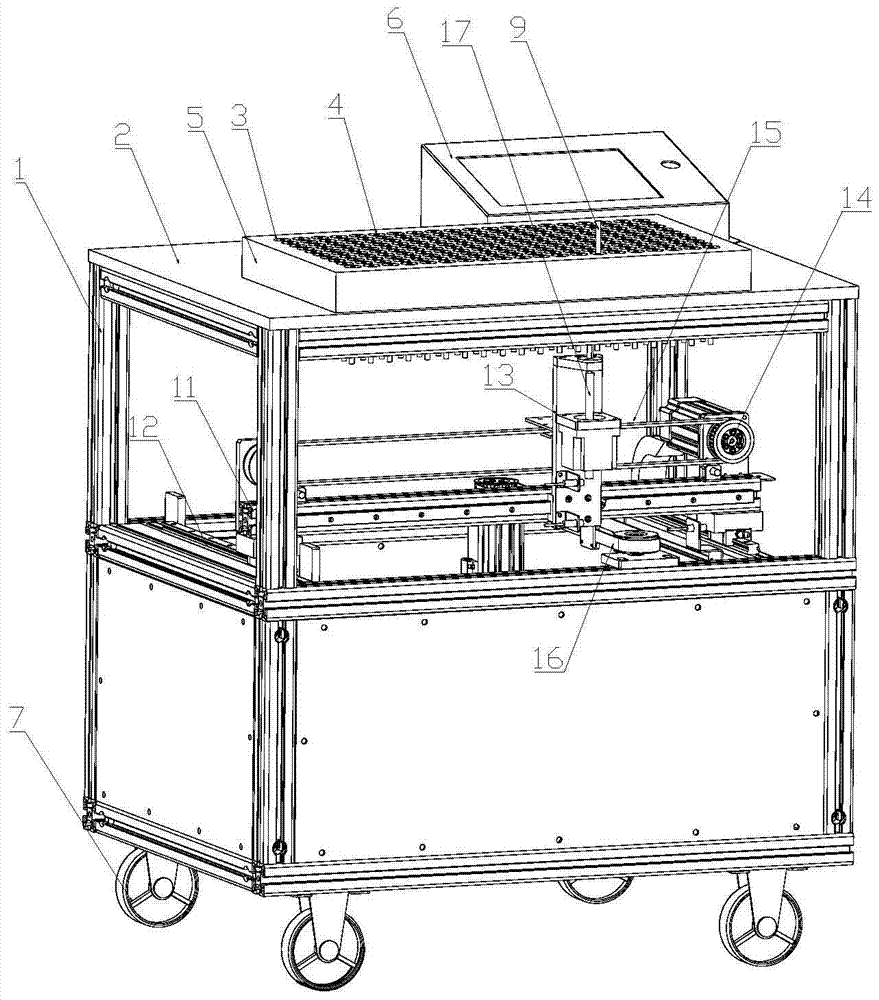

[0027] Such as figure 1 and figure 2 As shown, the wire number identification system includes a wire rack, a bobbin 8, an actuator and a control terminal; the wire rack includes a box body 1 and a wire rack 2 located above the box body 1, and a plurality of wire shaft grooves 3 are evenly distributed on the wire rack platform 2 , The bottom of the bobbin groove 3 has a through hole, so that the bobbin groove and the hollow box body 1 are connected. All insert a bobbin rod 4 in the through hole of each bobbin groove 3, the rod diameter of the bobbin rod 4 matches the aperture of the through hole of the bobbin groove 3, and the bobbin rod 4 can move up and down along the bobbin groove 3 through holes; There is a protruding structure on the top, the protruding structure is located above the through hole of the bobbin groove 3, and can be stuck at the through hole of the bobbin groove 3, so that the bobbin rod 4 does not fall; each bobbin rod 4 is interspersed with at least one ...

Embodiment 2

[0044] The difference from Embodiment 1 is that on the bobbin stand 2, a boss 5 is provided in the region where the bobbin groove 3 is located, and on the boss 5, a slot hole with the same aperture as the bobbin groove 3 is provided at a position corresponding to the bobbin groove 3 . Due to the limited thickness of the wire stand platform 2, after the bobbin rod 4 is released, there is no guide mechanism, which is prone to deflection, and the effect of the boss 5 is to guide the bobbin rod 4.

Embodiment 3

[0046] This embodiment provides a more intelligent and efficient line number identification method. The method for obtaining the process is different from that in Example 1.

[0047] The control terminal also includes card reading equipment and electronic tag cards. Each electronic label card is assigned an ID number, and each ID number corresponds to an order number information. The card reading device communicates with the order management system. The card reading device reads the card number information and transmits it to the order management system. The order number corresponding to the ID number is captured in the order management system. The order number is then transmitted to the process management system, and the process information is captured from the process management system.

[0048] Subsequently, the shaft number information and position information of the bobbin rod 4 stored corresponding to the wire number are searched in the memory, the actuator control uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com