Small-size multifunctional forest tending leftover collecting system

A collection system and multi-functional technology, applied in the field of collection systems, can solve the problems of reduced operating efficiency, limited operating environment space, small size, etc., and achieve the effects of reducing the total operating cost, improving operating efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

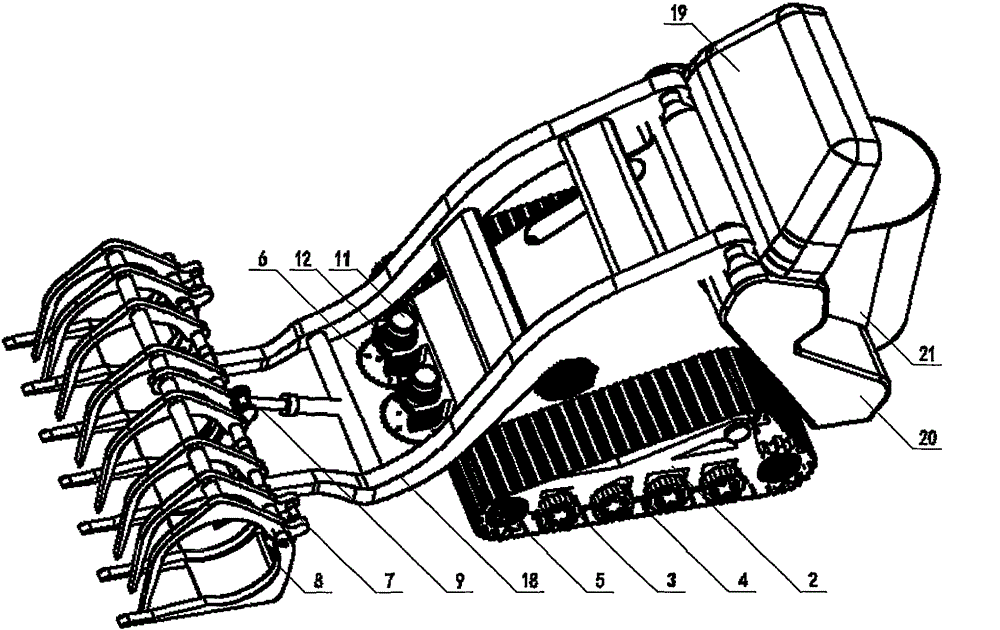

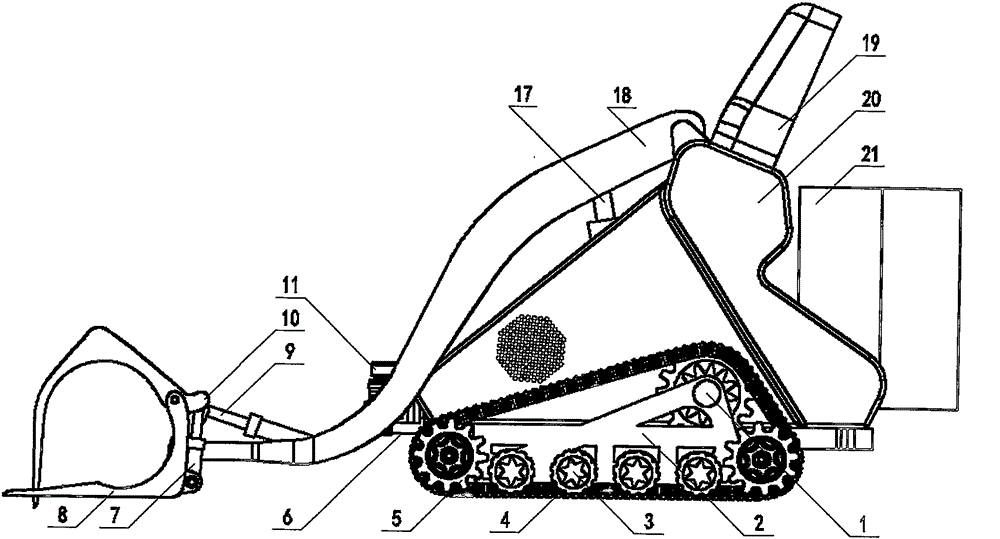

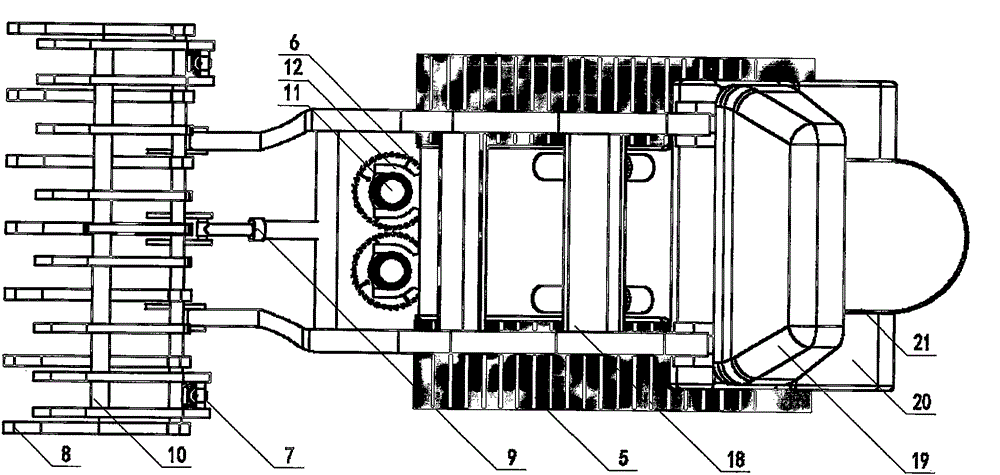

[0019] Such as Figure 1~3 As shown, the small multifunctional forest tending residue collection system of the present invention comprises a chassis 2, a car shell 20 positioned on the chassis 2, a driver's seat 21 positioned at the rear of the car shell 20, and a hinge at the top of the car shell 20. arm 18, the chassis 2 is provided with a boom lifting hydraulic cylinder 17, and the boom lifting hydraulic cylinder 17 is connected with the boom 18 to lift the boom 18;

[0020] The free end of the moving arm 18 is hinged with a gripper frame, and the gripper frame is provided with multiple groups of mutually engaging lower side grippers 8 and upper side grippers 10, and the lower side grippers 8 are fixed on the grippers. On the frame, the upper side grabber 10 is hinged on the grabber frame, and the grabber hydraulic cylinder 7 is also provided on the grabber frame, and the grabber hydraulic cylinder 7 can open and press the upper side grabber 10 tight; the boom 18 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com