A kind of reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and support layer, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., and can solve problems such as poor chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of reverse osmosis membrane provided by the invention comprises the following steps:

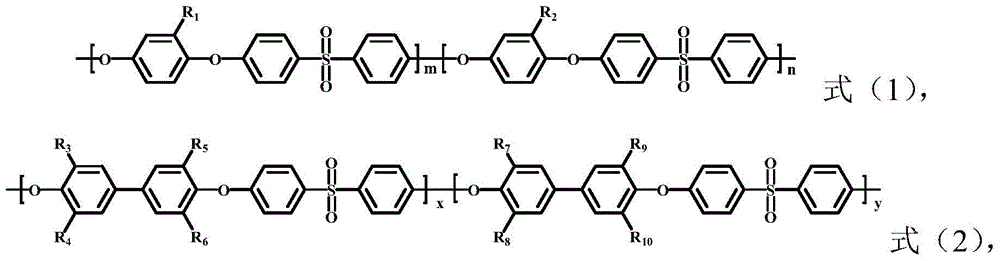

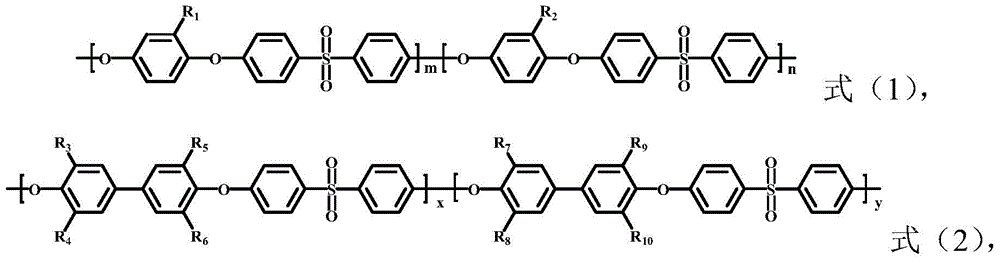

[0037] (1) forming a support layer containing a mixture of halogenated polyethersulfone represented by formula (1) and / or formula (2) and polysulfone and / or non-halogenated polyethersulfone;

[0038] (2) forming a separation layer on one surface of the support layer, the separation layer being a polyamide layer;

[0039]

[0040]

[0041] Among them, R 1 with R 2 The same or different, each independently CH 2 X or CH 3 , and R 1 with R 2 not at the same time as CH 3 , X is a halogen atom; R 3 -R 10 The same or different, each independently CH 2 Y or CH 3 , and R 3 -R 10 not at the same time as CH 3 , Y is a halogen atom; m+n=A, A is an integer of 50-250; x+y=W, and W is an integer of 80-300.

[0042] The halogen atom may be a fluorine atom, chlorine atom, bromine atom or iodine atom, but from the viewpoint of availability of raw materials, th...

preparation example

[0053] In the following preparation examples, examples and comparative examples:

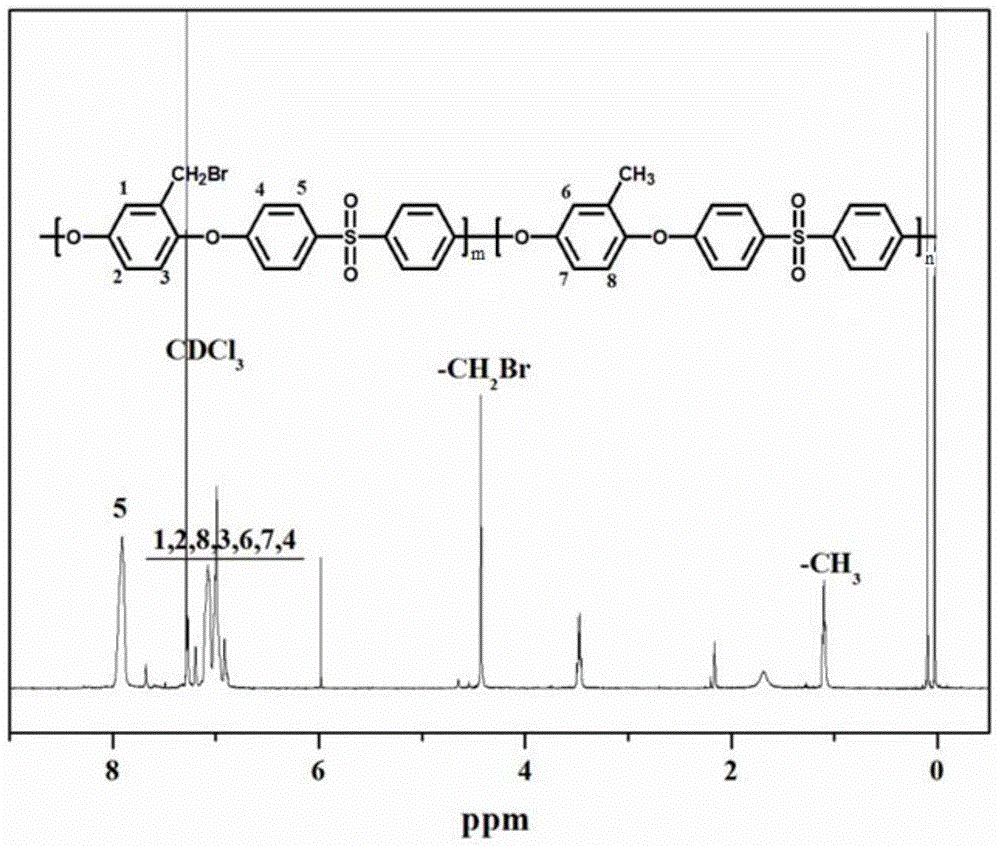

[0054] (1) The nuclear magnetic spectrum of brominated polyether sulfone PES-Br and brominated polyether sulfone PAES-Br adopts Swiss Bruker company AVANCE DRX400MHz nuclear magnetic resonance spectrometer to measure, and solvent is deuterated chloroform; Number average molecular weight adopts 410 of Waters company Gel permeation chromatography was used for determination, wherein THF was used as the mobile phase, narrow distribution polystyrene was used as the standard sample, and the test temperature was 25°C.

[0055] (2) The degree of bromination of brominated polyethersulfone PES-Br is calculated by nuclear magnetic integration, and the specific calculation formula is as follows:

[0056]

[0057] Among them, ∑H a Represent-CH 2 The sum of the peak areas of hydrogen atoms in Br, ΣH b Represent-CH 3 The sum of the peak areas of the hydrogen atoms, n represents the degree of bromination...

Embodiment 1

[0073] This example is used to illustrate the reverse osmosis membrane provided by the present invention and its preparation method.

[0074] Prepare reverse osmosis membrane according to the method of comparative example 1 and carry out the mensuration of water flux and desalination rate, difference is, described polysulfone is replaced with the mixture of the PES-Br of 1 weight part and the polysulfone of 16 weight parts, obtain reverse osmosis The permeable membrane M1, wherein the support layer has a thickness of 50 microns, and the separation layer has a thickness of 0.31 microns. The water flux and desalination rate of the reverse osmosis membrane M1 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com