A kind of preparation method of ultrathin metal shell nanoparticle

A nanoparticle and ultra-thin metal technology is applied in the field of preparation of ultra-thin metal shell nanoparticles to achieve the effects of easy implementation, simple operation and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

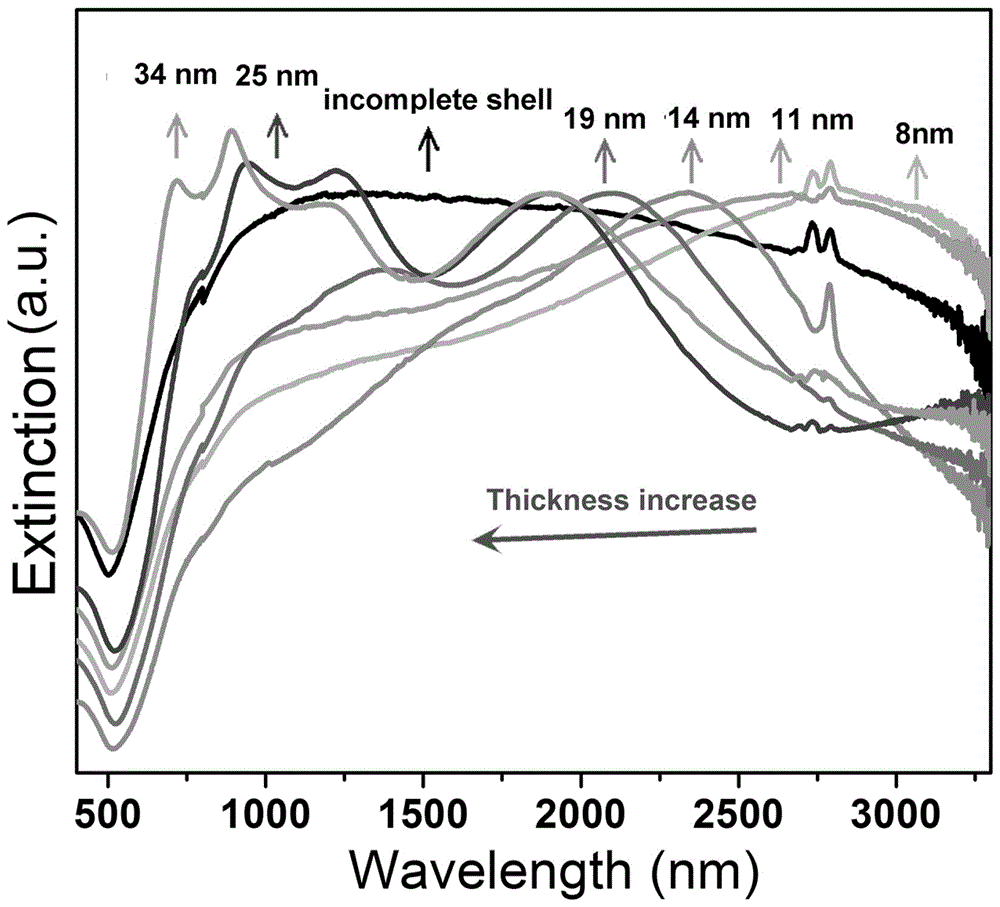

Method used

Image

Examples

Embodiment 1

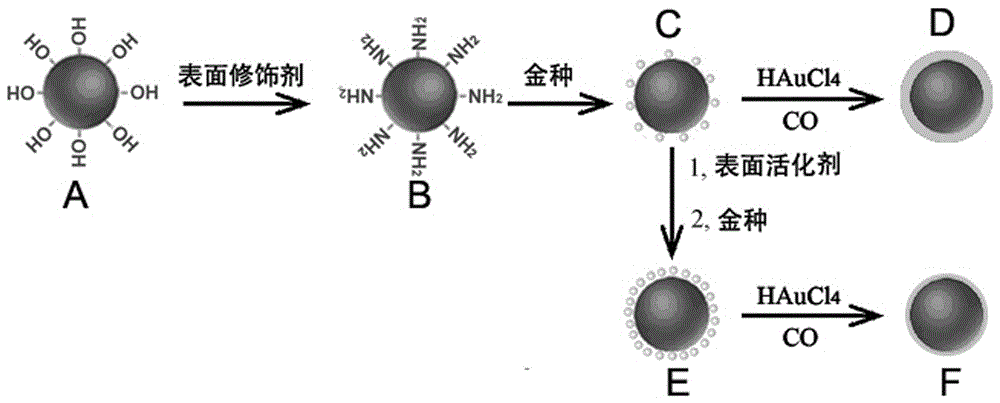

[0044] The preparation of ultra-thin gold-shell silica nanoparticles is carried out according to the following process steps:

[0045] (1) Preparation of silica colloidal microspheres with hydroxyl groups on the surface: Mix 150mL of isopropanol, 60mL of water and 30mL of ammonia water evenly at room temperature, control the stirring speed at 270-300rpm, add 14mL of ethyl orthosilicate dropwise to the system ester, the rate of addition was 1mL / min, the reaction temperature was controlled at 25-30°C, and the reaction time was 30 minutes. The silica colloidal microspheres were obtained by centrifugation. The silica colloidal microspheres were dispersed in ethanol and ultrasonically oscillated for 10 minutes to obtain Hydroxyl silica colloidal microspheres;

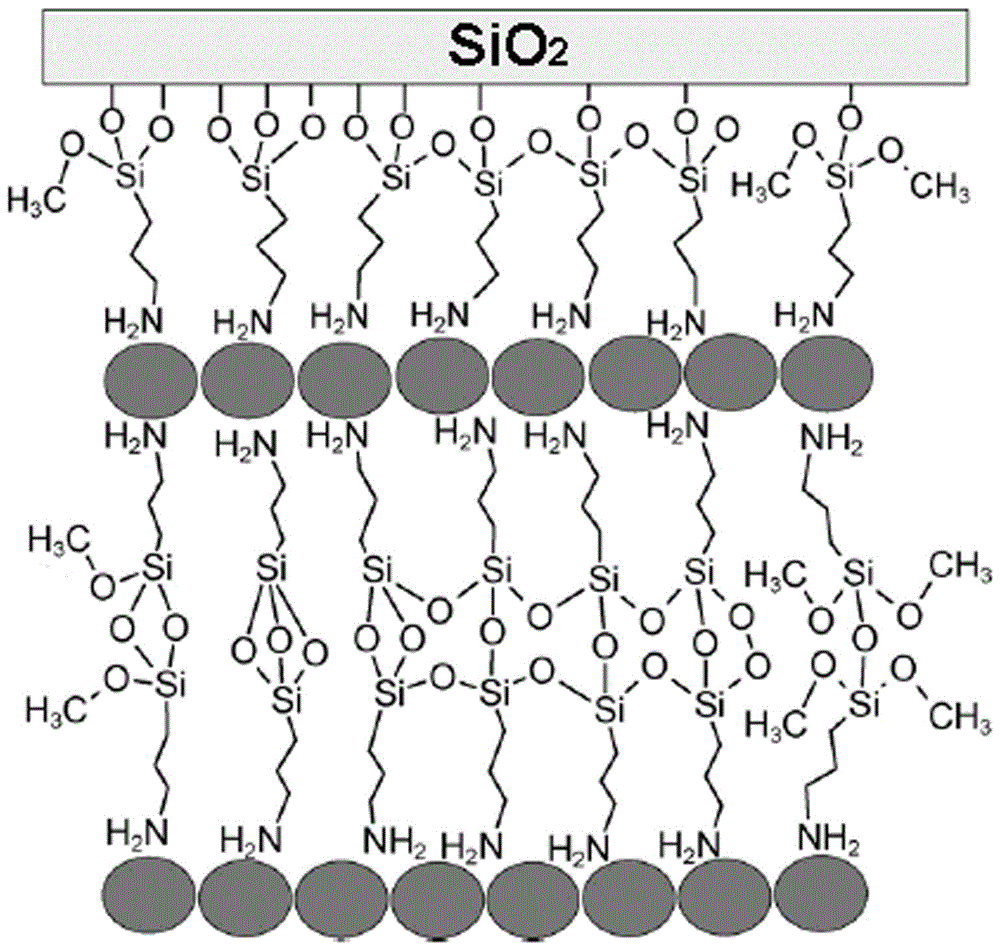

[0046] (2) Surface modification of silica colloidal microspheres: add aminopropyltrimethoxysilane dropwise to the ethanol solution of silica colloidal microspheres with hydroxyl groups on the surface, the amount of aminoprop...

Embodiment 2

[0052] The preparation of ultra-thin gold-shell polystyrene nanoparticles is carried out according to the following process steps:

[0053] (1) Preparation of polystyrene colloidal microspheres with hydroxyl groups on the surface: mix 30mL water, 40mL ethanol, 0.5g sodium lauryl sulfate and 0.2g potassium persulfate at room temperature, and control the stirring speed to 270-300rpm, Add 10mL of styrene and 0.5g of divinylbenzene, control the reaction temperature to 50-60°C, and the reaction time is 10h, under nitrogen protection throughout the reaction, centrifuge to obtain polystyrene colloidal microspheres; disperse polystyrene colloidal microspheres in concentrated Sonicate in sulfuric acid for 50 minutes, and centrifuge to obtain polystyrene colloidal microspheres with sulfonic acid groups on the surface;

[0054] (2) Surface modification of polystyrene colloidal microspheres: disperse polystyrene colloidal microspheres with sulfonic acid groups on the surface into ethanol,...

Embodiment 3

[0060] The preparation of the ultra-thin gold shell layer ferric iron tetroxide fusiform colloidal particle is carried out according to the following process steps:

[0061] (1) Preparation of ferric oxide fusiform colloidal particles with hydroxyl groups on the surface: mix water and potassium dihydrogen phosphate evenly at room temperature, wherein the concentration of potassium dihydrogen phosphate in the aqueous solution is 5 × 10 -4 M, control the stirring speed at 270-300rpm, add ferric chloride, control the concentration of ferric chloride in the aqueous solution to 0.05M, control the reaction temperature at 85-90°C, and the reaction time is 36h, centrifuge to obtain the fusiform iron tetraoxide Colloidal particles; disperse ferric oxide fusiform colloidal particles in ethanol and ultrasonically vibrate for 30 minutes to obtain ferric ferric oxide fusiform colloidal particles with hydroxyl groups on the surface, and its scanning electron microscope picture is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com