Pneumatic tire

A technology for pneumatic tires and treads, applied in pneumatic tires, reinforcement layers of pneumatic tires, motorcycle tires, etc., can solve problems such as impaired riding comfort, and achieve excellent riding comfort, handling stability and high-speed stability. Improves and realizes the effect of handling stability and high-speed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

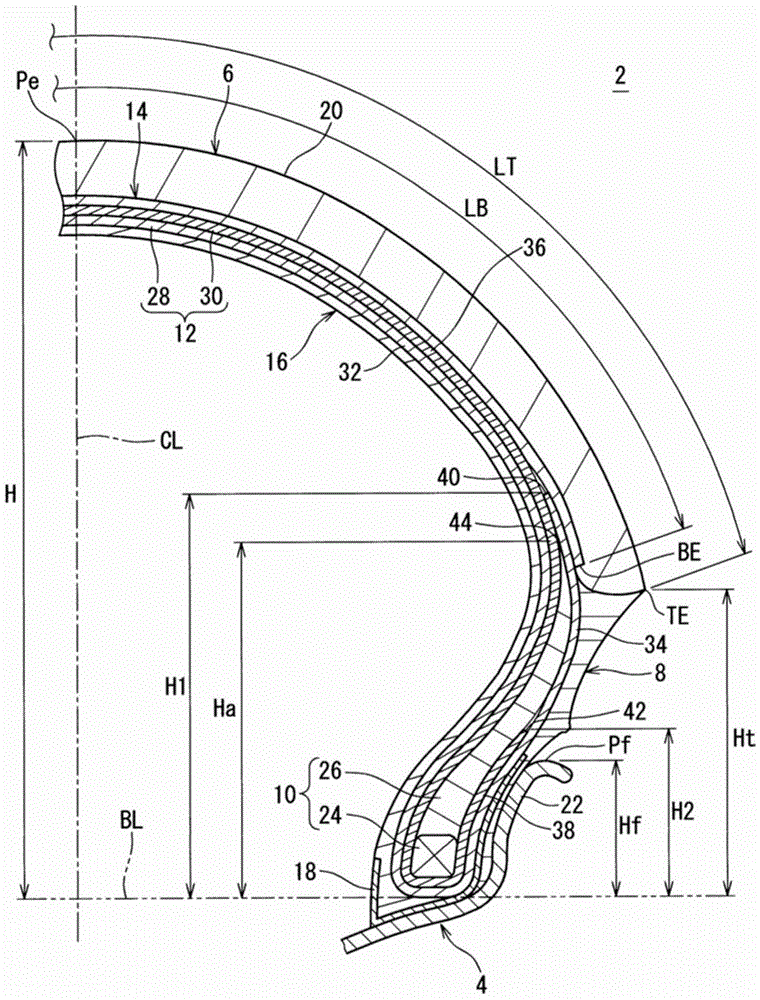

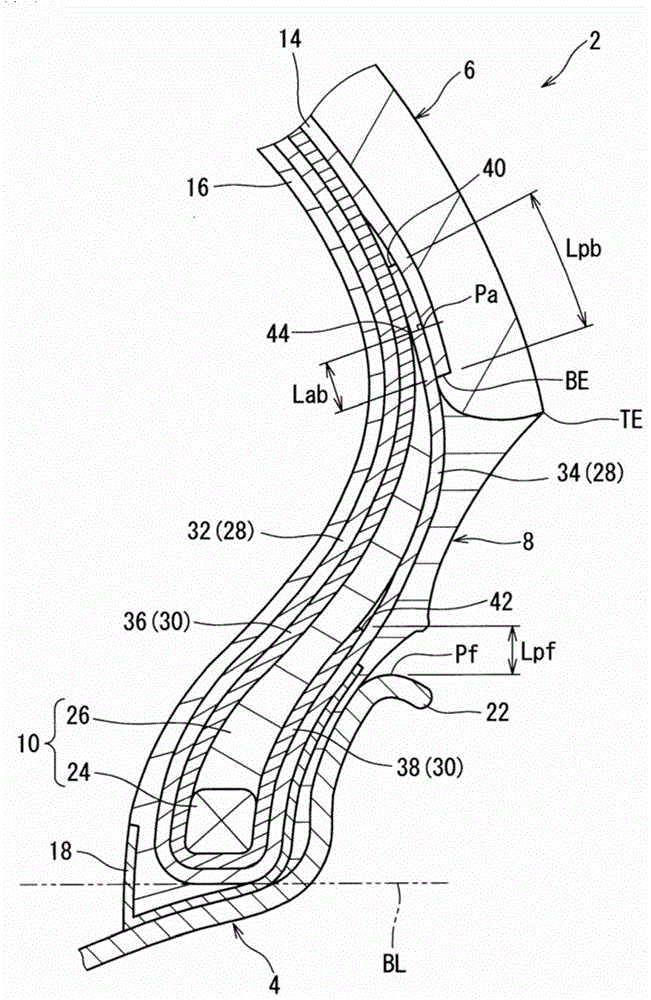

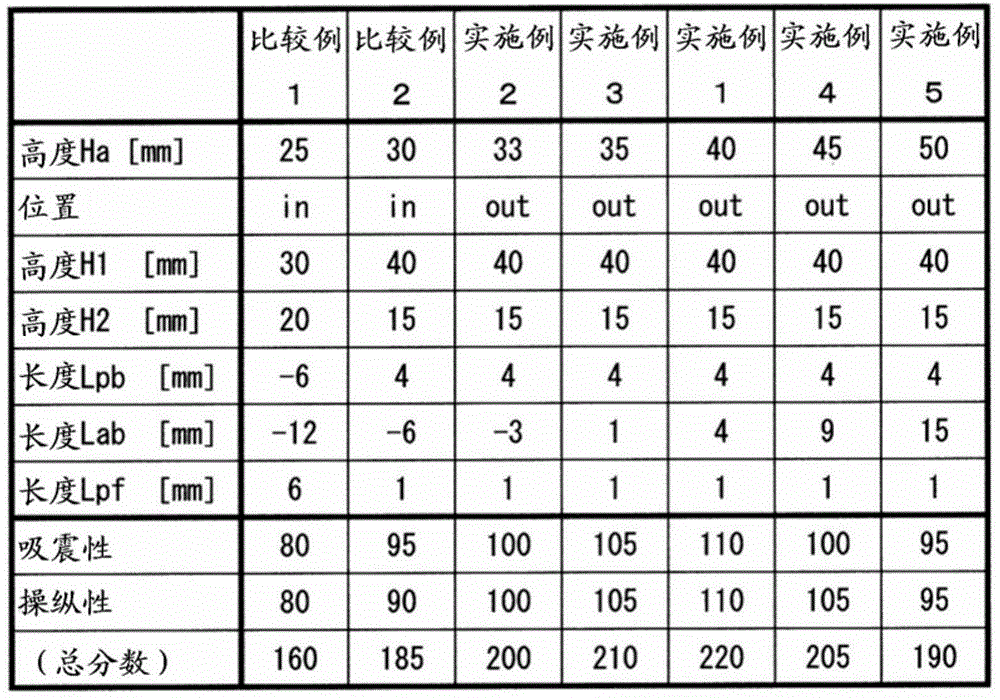

[0071] made Figure 1 ~ Figure 2 tires shown. The size of this tire is 120 / 70ZR17. The outer end of the apex is located radially outward from the end TE of the tread surface. This is indicated by "out" in the "Position" column of the table. The height Ha of the apex was 40 mm, the height H1 of the folded portion of the first ply was 40 mm, and the height H2 of the folded portion of the second ply was 15 mm. The length Lpb from the end BE of the reinforcing layer to the end of the folded-back portion of the first ply was 4 mm. The length Lab from the end BE of the reinforcing layer to the outer end of the apex is 4 mm. The radial length Lpf from the outer end Pf of the flange to the end of the turned-back portion of the second ply was 1 mm.

Embodiment 2~5 and comparative example 2

[0073] The tires of Examples 2 to 5 and Comparative Example 2 were obtained in the same manner as in Example 1 except that the height Ha was adjusted and the length Lab was set as shown in Table 1 below. In Comparative Example 2, the outer end of the apex rubber is positioned radially inward of the end portion TE of the tread surface. This is indicated by "in" in the "Position" column of the table.

Embodiment 6~11

[0077] Except for adjusting the height H1 and the height H2, and setting the length Lpb and the length Lpf as shown in Table 2 below, the rest were the same as in Example 1, thereby obtaining tires of Examples 6 to 11. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com