Hinge type car protective cover

A hinged, protective cover technology, applied to vehicle parts, movable outer sheaths, transportation and packaging, etc., can solve the problems of complex structure of the protective cover, large wear of the protective cover, complicated operation methods, etc., to achieve different operating methods Complex, strong protection ability, good safety protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

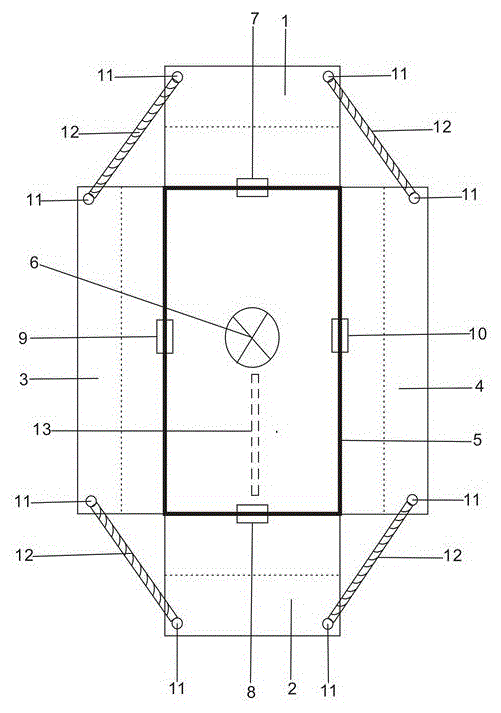

[0021] Example 1: Such as figure 1 As shown, a hinged automobile protective cover includes a front cover 1, a rear cover 2, a left side cover 3, a right side cover 4, a storage box 5, a control system 6, a hinge 7, a hinge 8, a hinge 9, and a hinge 10, It is characterized in that: the front cover 1 is installed on the front side of the storage box 5; the rear cover 2 is installed on the rear side of the storage box 5; the left side cover 3 is installed on the left side of the storage box 5; The side cover 4 is installed on the right side of the storage box 5; the storage box 5 is provided with a hinge 7 and a driving device corresponding to the front cover 1, and the front cover 1 can be opened by the hinge 7 and the driving device on the storage box 5. Opening and closing movement; the storage box 5 is provided with a hinge 8 and a driving device corresponding to the rear cover 2, and the rear cover 2 can be opened and closed by the hinge 8 and the driving device on the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com