Conveying belt for bottom plate of compartment vehicle

A van floor and conveyor belt technology, which is applied in the field of cargo transportation, can solve the problems of reduced transmission efficiency, low transmission efficiency, and poor stability, and achieve high transmission efficiency, avoid slipping and offset, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

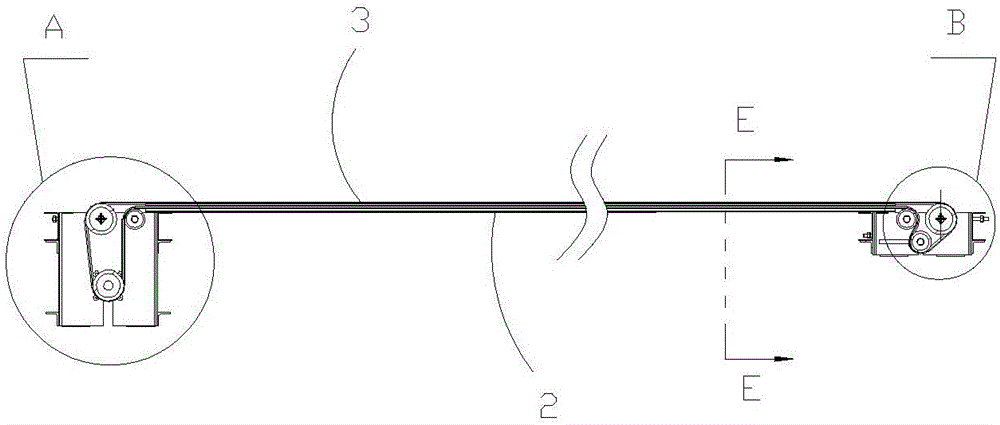

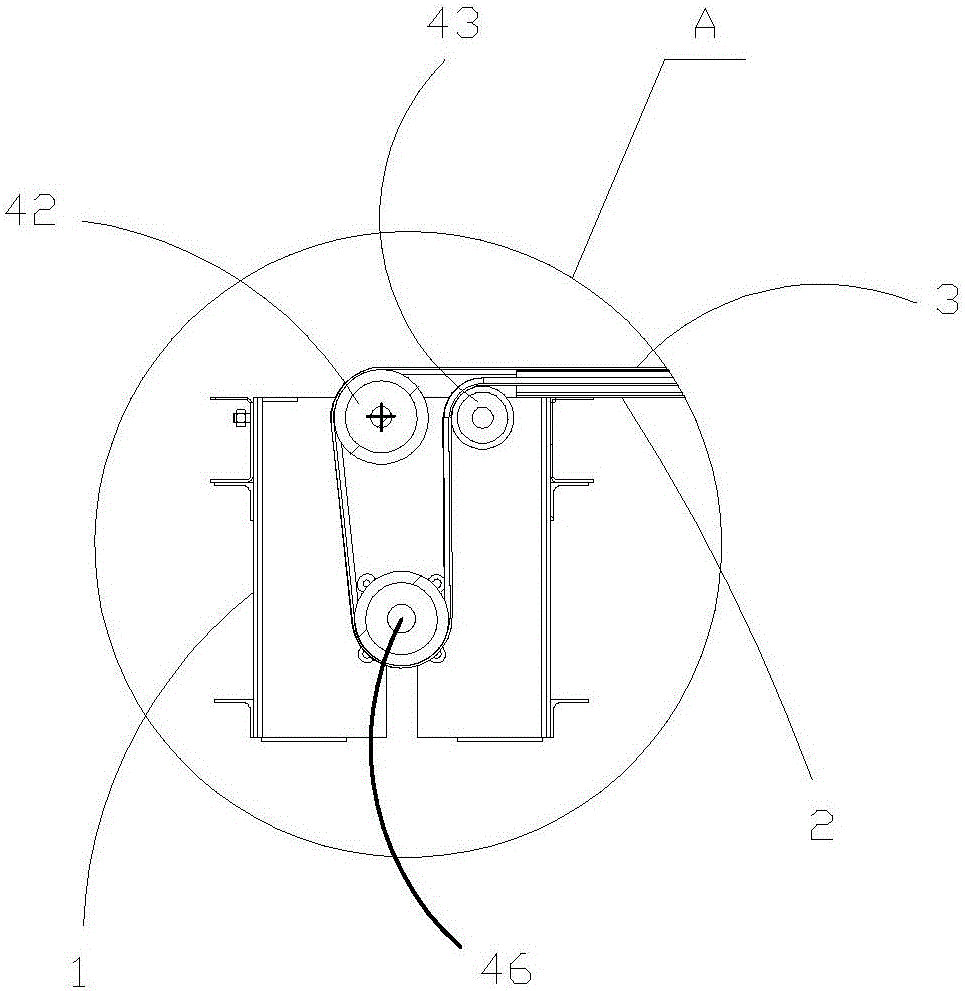

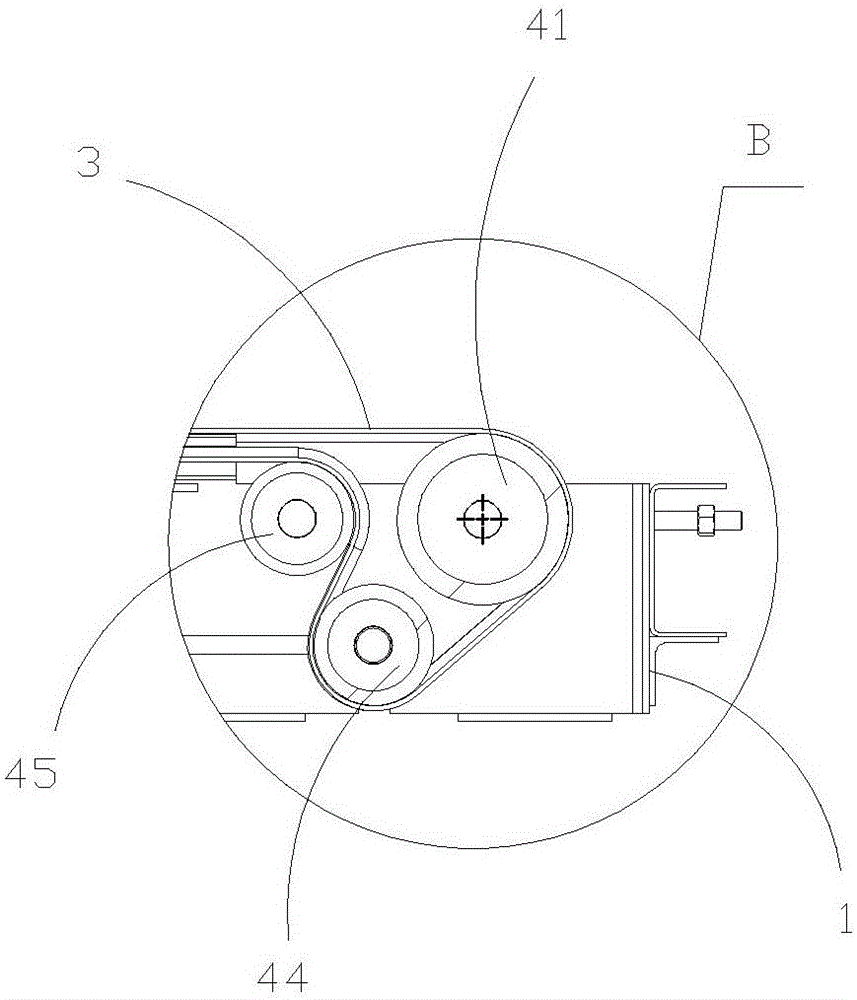

[0018] Such as Figure 1-Figure 7 As shown, a conveyor belt for the floor of a van of the present invention includes a frame 1, a floor located above the frame 1, a driving wheel 46 and a driven wheel 41 installed at both ends of the frame 1, and connecting the driving wheel 46 and a number of conveyor belts 3 of the driven wheel 41, a power mechanism (not shown) that drives the driving wheel 46 to rotate, and a first guide wheel 43, a second guide wheel 45, and a third guide wheel 42, the bottom plate 2 includes A plurality of receiving cavities 22 arranged side by side along its width direction and passing through the front and rear ends of the conveyor belt 3 includes an upper side belt 32 located above the bottom plate and a lower side belt 33 passing through the receiving cavity 22. A guide wheel 43 and a second guide wheel 45 are lower side belt guide wheels, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com